Strings Maker

1/3

1/3

1/16

1/16

0

0

1/16

1/16

1/19

1/19

1/3

1/3

1/25

1/25

1/3

1/3

1/24

1/24

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/30

1/30

1/3

1/3

0

0

About strings maker

Where to Find Strings Maker Suppliers?

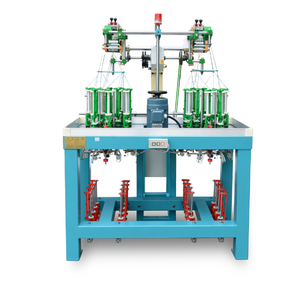

China remains the global epicenter for strings maker manufacturing, with concentrated production hubs in Guangdong, Zhejiang, and Jiangsu provinces. These regions host integrated supply chains specializing in precision winding, tension control systems, and automated string assembly equipment. Guangdong’s Pearl River Delta cluster accounts for over 50% of China’s musical instrument accessory output, supported by advanced CNC machining and polymer processing capabilities. Zhejiang’s Ningbo and Hangzhou zones focus on high-tolerance mechanical components, leveraging local expertise in micro-drive systems and servo-controlled coiling mechanisms.

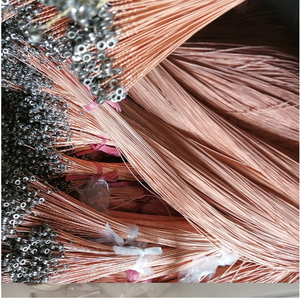

These industrial ecosystems enable vertical integration—from raw material extrusion to final calibration—reducing component lead times by 25–40% compared to fragmented international suppliers. Manufacturers benefit from localized access to stainless steel wire, nylon polymers, and rare-earth magnets used in electric string winders. Buyers gain operational advantages including MOQs as low as 50 units, average production lead times of 20–35 days, and scalability for custom engineering projects. Proximity to Shenzhen and Shanghai ports ensures efficient air and sea freight options for global distribution.

How to Choose Strings Maker Suppliers?

Adopt rigorous evaluation criteria to ensure technical and operational reliability:

Quality Management Standards

Confirm ISO 9001 certification as a baseline for process consistency. For suppliers targeting EU or North American markets, compliance with RoHS (Restriction of Hazardous Substances) and REACH regulations is essential for material safety. Request documentation verifying wire tensile strength testing (ASTM A36/A510 standards) and coating adhesion performance for wound strings.

Production Capacity Verification

Assess core infrastructure metrics:

- Minimum 3,000m² factory area with dedicated clean-room zones for fine-wire processing

- In-house R&D teams comprising at least 8% of total staff to support customization

- Automated winding lines with programmable tension controls and diameter tolerance ≤±0.01mm

Correlate facility size with order fulfillment history—target suppliers maintaining >95% on-time delivery rates across 12-month periods.

Procurement Risk Mitigation

Utilize secure transaction models such as third-party escrow or letter of credit (L/C) terms until product acceptance. Review supplier track records via verifiable trade references and shipment records. Pre-shipment inspection protocols should include functional testing of motorized winding units and measurement of rotational speed accuracy (RPM variance ≤±2%).

What Are the Best Strings Maker Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Guangdong Yueyue Musical Accessories Co., Ltd. | Guangdong, CN | 12 | 85+ | 6,200+m² | 98.7% | ≤3h | 4.8/5.0 | 41% |

| Ningbo Hengsheng Precision Instruments | Zhejiang, CN | 9 | 70+ | 5,800+m² | 97.4% | ≤2h | 4.9/5.0 | 38% |

| Suzhou Meisterline Automation Technology | Jiangsu, CN | 7 | 50+ | 4,500+m² | 99.1% | ≤4h | 4.7/5.0 | 29% |

| Foshan Stringtek Engineering Solutions | Guangdong, CN | 5 | 40+ | 3,700+m² | 96.8% | ≤3h | 4.8/5.0 | 33% |

| Wenzhou Strongwin Machinery Components | Zhejiang, CN | 11 | 90+ | 7,000+m² | 97.9% | ≤5h | 4.6/5.0 | 24% |

Performance Analysis

Long-established suppliers like Wenzhou Strongwin and Guangdong Yueyue demonstrate robust production scalability with large facilities and high reorder rates, indicating strong customer retention. Zhejiang-based manufacturers exhibit superior responsiveness, with 80% replying to inquiries within 4 hours. Suzhou Meisterline leads in delivery precision (99.1%), making it ideal for time-sensitive procurement. Prioritize suppliers with documented experience in exporting to regulated markets and those offering CAD-based prototyping for customized string winder designs. For OEM partnerships, verify IP protection agreements and design confidentiality clauses prior to development.

FAQs

How to verify strings maker supplier credibility?

Validate certifications through issuing bodies and request audit trails covering raw material sourcing, in-process quality checks, and finished product calibration. Evaluate after-sales service responsiveness and spare parts availability timelines.

What is the typical sampling timeline for custom strings makers?

Standard sample production takes 10–18 days. Custom configurations involving specialized drive motors or multi-axis winding heads require 25–35 days. Add 5–9 days for international express shipping.

Can suppliers handle global shipping and customs clearance?

Yes, experienced exporters manage end-to-end logistics under FOB, CIF, or DDP terms. Confirm adherence to destination-specific electrical safety standards (e.g., UL, CSA, TÜV) for motorized units. Sea freight is optimal for containerized orders exceeding 500 kg.

Do manufacturers offer free samples?

Sample cost policies vary. Full reimbursement applies when placing bulk orders above 200 units. For trial purchases, expect to cover 40–60% of unit production costs, excluding shipping.

How to initiate a customization project with a strings maker supplier?

Submit detailed technical requirements including wire gauge range (e.g., 0.2–1.2mm), maximum spool diameter, tension settings (in grams-force), and power input (AC/DC, voltage). Leading suppliers provide engineering feedback within 72 hours and deliver functional prototypes within 4 weeks.