Supplier Monitoring System

Top sponsor listing

Top sponsor listing

About supplier monitoring system

Where to Find Supplier Monitoring System Manufacturers?

China remains the central hub for monitoring system production, with key manufacturing clusters in Guangdong and Guangzhou provinces driving innovation and volume output. Shenzhen and Guangzhou host a dense network of electronics manufacturers specializing in embedded sensors, wireless communication modules, and IoT-integrated monitoring solutions. These regions benefit from mature supply chains for PCBs, microcontrollers, and display components, enabling rapid prototyping and scalable production.

The industrial ecosystem supports vertical integration across design, firmware development, and assembly, reducing component lead times by 20–35% compared to non-specialized regions. Suppliers in this zone typically operate within 50km of tier-one component vendors and logistics hubs, facilitating faster order fulfillment. Buyers can expect standard lead times of 15–30 days for pre-configured systems, with cost advantages of 15–25% due to localized sourcing and optimized labor efficiency. The concentration of technical talent also enables agile customization for data logging, mobile app integration, and sensor fusion applications.

How to Choose Supplier Monitoring System Manufacturers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical & Functional Compliance

Confirm adherence to relevant safety and electromagnetic compatibility standards such as CE, RoHS, and FCC. For industrial or hazardous environments, verify intrinsic safety certifications (e.g., ATEX, IECEx) where applicable. Evaluate system specifications including sensor types (radar, acoustic emission, gas, structural strain), data sampling rates, storage capacity, and remote access capabilities via mobile apps or cloud platforms.

Production and Customization Capacity

Assess manufacturer capabilities through the following indicators:

- Minimum facility size of 2,000m² for sustained batch production

- In-house R&D teams supporting firmware updates, UI/UX customization, and API integration

- Flexible configuration options: color, material, LED displays, labeling, packaging, and OEM branding

Cross-reference product listings with on-time delivery performance (target ≥94%) and reorder rate (≥20%) to gauge reliability and customer satisfaction.

Quality Assurance and Transaction Security

Prioritize suppliers with documented quality management systems and responsive after-sales support (response time ≤4 hours). Utilize secure payment mechanisms tied to shipment milestones. Conduct sample testing to validate sensor accuracy, environmental durability, and software functionality before scaling orders. Request demonstration units or field trial reports for mission-critical deployments.

What Are the Leading Supplier Monitoring System Manufacturers?

| Company Name | Main Products | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Customization Options | Product Range |

|---|---|---|---|---|---|---|---|

| QingCheng AE Institute (Guangzhou) Co., Ltd. | Testing Equipment, Acoustic Emission, Structural Health Monitoring | 100% | 25% | ≤4h | US $10,000+ | Multi-channel AE systems, unattended operation, wireless transmission | $630–$5,838 per set |

| Hong Kong Wanhong International Limited | Surveillance Systems, CCTV, POE/WiFi Camera Solutions | 100% | 16% | ≤7h | US $2,000+ | Channel count, NVR storage, AHD/WiFi support | $74–$383 per piece |

| Shenzhen Cisbo Technology Co., Ltd. | Car Reversing Aid, Safety Driving Systems, Auto Electronics | 89% | 16% | ≤3h | US $60,000+ | LED display, logo, packaging, radar sensor, mobile app | Multiple SKUs across automotive safety |

| Guangzhou Pingfu Electronics Co., Ltd. | Blind Spot Detection, AI Truck BSD, 4G Vehicle Tracking | 94% | 20% | ≤2h | US $50,000+ | Sensor frequency (77GHz), camera integration, 4G connectivity | $22.80–$115 per set |

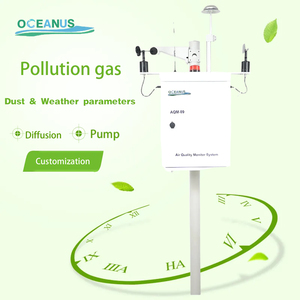

| WOBO Industrial Group Inc | Gas Analyzers, Air Quality Monitors, Dust Samplers | - | - | ≤3h | - | Detection range (ppm/ug/m³), IP66 rating, constant flow design | $290–$300 per piece |

Performance Analysis

QingCheng AE Institute and Hong Kong Wanhong International achieve perfect on-time delivery records, indicating robust production planning and inventory control. Guangzhou Pingfu Electronics stands out with a 94% on-time rate and industry-leading ≤2-hour response time, supported by a high reorder rate of 20%, suggesting strong post-sale service execution. Shenzhen Cisbo leads in online revenue generation (US $60,000+), reflecting broad market reach in automotive monitoring systems with extensive customization—particularly in mobile app integration and branded packaging. WOBO Industrial targets niche environmental monitoring applications with standardized pricing and fast response, though transaction metrics are unverified. For high-volume or regulated deployments, prioritize suppliers with proven compliance documentation and scalable infrastructure.

FAQs

How to verify monitoring system supplier reliability?

Cross-check stated certifications (CE, RoHS) with official databases or third-party inspection reports. Request evidence of internal QA processes, including burn-in testing, environmental stress screening, and firmware validation. Analyze historical buyer feedback focused on long-term system stability and technical support responsiveness.

What is the typical lead time for customized monitoring systems?

Standard configurations ship within 15–20 days. Custom firmware, sensor integration, or branded interfaces extend timelines to 30–45 days depending on complexity. Prototypes for new designs are typically delivered within 3–4 weeks after specification finalization.

Do suppliers support global shipping and compliance?

Yes, most established manufacturers offer international logistics via air or sea freight under FOB or CIF terms. Confirm that devices comply with destination-country regulations for radio frequency emissions (e.g., FCC Part 15 in the U.S.) and electrical safety (e.g., UL, CSA). Pre-shipment inspections are recommended for bulk orders.

Are samples available for testing?

Sample availability depends on unit value and customization level. Suppliers often provide samples at 1.5–2x unit price, which may be credited toward first orders exceeding 10 units. For high-end systems (e.g., structural health monitors), expect sample fees covering full production cost unless under NDA-based collaboration.

What customization options are commonly offered?

Manufacturers routinely support modifications in housing material, color coding, display type, sensor sensitivity, data logger capacity, and wireless protocols. Advanced options include private-label mobile applications, custom calibration curves, multi-language interfaces, and API access for enterprise integration. Submit detailed technical requirements early in negotiations to assess feasibility and tooling costs.