Supply Chain Management Order Processing

CN

CN

CN

CN

About supply chain management order processing

Where to Source Supply Chain Management Order Processing Solutions?

Global supply chain management and order processing services are increasingly concentrated in China’s technology and manufacturing hubs, particularly in Shenzhen, Guangzhou, and Fuzhou. These regions host specialized firms integrating software development, hardware customization, and digital logistics coordination into unified order fulfillment systems. Shenzhen leads with a dense ecosystem of electronics innovators and app developers, enabling rapid prototyping and integration of IoT-enabled tracking and inventory modules. Guangzhou suppliers leverage proximity to industrial LED and display manufacturers to deliver real-time warehouse visualization tools, while Fuzhou-based trading companies focus on scalable footwear and consumer goods order processing with integrated labeling and packaging automation.

The clustering effect reduces component sourcing time by 25–40% through localized supplier networks for PCBs, microcontrollers, and cloud infrastructure. This enables faster deployment of customized order management interfaces—typically within 15–30 days from design finalization. Buyers benefit from modular service offerings, including ODM/OEM software builds, API integrations with ERP systems, and mobile application development tailored to B2B or e-commerce workflows. Cost efficiency is further enhanced by competitive labor rates in tech development (averaging $300–$500/month per engineer) and flexible engagement models ranging from fixed-price packages to time-and-materials contracts.

How to Evaluate Supply Chain Management Order Processing Providers?

Selecting reliable partners requires rigorous assessment across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm expertise in full-stack development (Android/iOS, web platforms, backend databases) and integration with common logistics APIs (e.g., shipping carriers, warehouse management systems). Suppliers should demonstrate experience building custom eCommerce applications, POS systems, or inventory dashboards. For hardware-integrated solutions—such as smart LED displays used in warehouse status monitoring—verify compatibility with control units, power supply specifications, and environmental resilience (e.g., waterproofing, high brightness for outdoor use).

Customization & Development Scope

Assess the depth of customization offered:

- Support for logo branding, UI/UX personalization, and multilingual interfaces

- Flexible OEM/ODM frameworks allowing clients to define feature sets and data architecture

- Prototyping timelines: expect 7–14 days for initial app mockups or display designs

- Revisions policy and post-launch support terms

Cross-reference stated capabilities with actual product listings showing completed projects in mobile apps, LED control panels, or online sales platforms.

Operational Reliability Metrics

Prioritize suppliers with documented performance records:

- On-time delivery rate ≥95%

- Average response time ≤2 hours

- Reorder rate above 30%, indicating client retention

- Verified history of online revenue generation (e.g., >US$200,000 annually)

Use these metrics as proxies for organizational stability and service consistency.

What Are the Leading Supply Chain Management Order Processing Suppliers?

| Company Name | Core Services | Min. Order Value | Customization Options | On-Time Delivery | Avg. Response | Revenue Transparency | Reorder Rate | Verification Status |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Kuaiji Interactive Technology Co., Ltd. | Mobile App Design, Custom Software | $100/set | Logo, UI, ODM/OEM | 100% | ≤7h | Not disclosed | - | Trusted service provider |

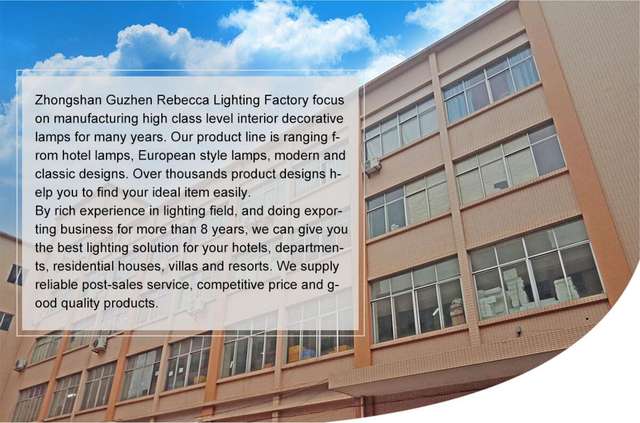

| Guangzhou Canyi Electronic Technology Co., Ltd. | LED Display Systems, Control Units | $400/m² | Size, color, resolution, material, logo, packaging | 95% | ≤3h | US $420,000+ | 46% | Custom Manufacturer |

| CRISTA TECHNOLOGIES LLP | eCommerce Apps, Website Development | $300/unit | Limited to functional scope | 75% | ≤1h | US $400+ | - | Unverified |

| Shenzhen Efun Innovation Electronic Technology Co., Ltd. | Smart Furniture, Illuminated Displays | $42.50/unit | Design, lighting, size, logo | 92% | ≤2h | US $20,000+ | <15% | Unverified |

| Fuzhou Bosirui International Trading Co., Ltd. | Footwear Order Processing, Labeling | $0.99/pair (MOQ 1k) | Color, material, size, logo, packaging | 100% | ≤1h | US $200,000+ | <15% | Multispecialty Supplier |

Performance Analysis

Guangzhou Canyi stands out with a 46% reorder rate and comprehensive customization across screen size, resolution, and control systems, indicating strong client satisfaction in industrial display integration. Fuzhou Bosirui demonstrates robust order reliability (100% on-time delivery) and high annual revenue transparency, making it suitable for bulk consumer goods processing. Shenzhen Kuaiji offers low entry barriers ($100 minimum) for app development but slower response times, which may affect project agility. CRISTA TECHNOLOGIES, despite fast responsiveness, shows lower delivery performance (75%), suggesting potential workflow bottlenecks. Suppliers with verified manufacturer status and higher revenue disclosure (e.g., >US$200K) generally offer more stable operations for long-term partnerships.

FAQs

How to verify a supplier’s technical capability in order processing systems?

Request case studies or demo links for previously developed mobile apps, websites, or integrated LED control panels. Validate coding proficiency by asking for GitHub repositories or technical documentation. For hardware-linked systems, require schematics of control units, power requirements, and compatibility matrices.

What is the typical lead time for customized order management software?

Standard mobile or web application development takes 2–6 weeks depending on complexity. Simple eCommerce sites may be delivered in 10–15 days, while integrated supply chain platforms with API connections require 4–8 weeks. Prototypes are typically available within 7–10 days after requirement finalization.

Are there minimum order quantities for software or digital services?

Most providers do not enforce MOQs for digital services but require a minimum project value (typically $100–$300). For hardware-integrated solutions like smart displays or labeled footwear batches, MOQs range from 1 square meter to 500–2000 units depending on product type.

Can suppliers integrate order processing systems with existing ERP or inventory platforms?

Yes, many suppliers offer API-based integration with mainstream platforms such as Shopify, WooCommerce, SAP, or Oracle NetSuite. Confirm prior experience with your specific system and request test environment access before deployment.

What quality assurance measures should be required?

Insist on structured testing protocols including UI validation, load testing for concurrent users, and security audits for data handling. For physical components (e.g., LED panels), demand photometric reports, ingress protection ratings, and proof of compliance with electrical safety standards applicable to your market.