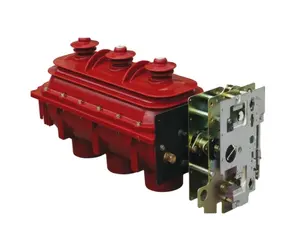

Switch Fuse

Top sponsor listing

Top sponsor listing

0

0

1/3

1/3

0

0

1/3

1/3

1/1

1/1

1/3

1/3

0

0

0

0

1/3

1/3

1/3

1/3

1/12

1/12

1/3

1/3

1/2

1/2

1/1

1/1

1/3

1/3

1/3

1/3

0

0

1/3

1/3

0

0

About switch fuse

Where to Find Switch Fuse Suppliers?

China remains the global epicenter for switch fuse manufacturing, with key production clusters concentrated in Zhejiang and Henan provinces. These regions host vertically integrated electrical equipment ecosystems that combine component sourcing, precision engineering, and export logistics within compact industrial zones. Zhejiang, particularly Yueqing City, is renowned as China’s low-voltage electrical hub, housing over 70% of national fuse and disconnector producers. Henan's Zhengzhou and Luoyang corridors specialize in medium- to high-voltage power distribution systems, supporting large-scale infrastructure projects through scalable fabrication capacity.

The clustering effect enables streamlined supply chains—raw materials like copper alloys, insulating ceramics, and thermoplastic housings are sourced within 50km, reducing lead times by 20–30%. Manufacturers benefit from shared tooling facilities, certified testing labs, and skilled labor pools trained in IEC 60269 and IEC 60947 standards. This integration allows suppliers to maintain MOQs as low as 1–5 units for sample validation while scaling to bulk orders exceeding 500 pieces with average delivery windows of 15–30 days. Export readiness is widespread, with most factories equipped for FOB, CIF, and DDP shipping terms across North America, Europe, and Southeast Asia.

How to Choose Switch Fuse Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certifications

Verify adherence to international safety and performance benchmarks. CE marking is essential for European market access, while UL or CSA alignment may be required for North American deployments. Confirm product conformity with IEC 60269 (fuse standards) and IEC 60947-3 (switch disconnectors). Request test reports on breaking capacity, temperature rise, dielectric strength, and mechanical endurance cycles.

Production Capability Assessment

Evaluate core manufacturing attributes:

- Minimum factory area of 2,000m² indicating dedicated assembly lines

- In-house capabilities including CNC stamping, injection molding, and automated contact welding

- Availability of design engineering support for custom configurations (e.g., pole count, current rating, DIN rail mounting)

- On-time delivery rate exceeding 97% as an indicator of production planning maturity

Cross-reference supplier claims with verifiable metrics such as online revenue volume and reorder rates, which reflect customer retention and product reliability.

Procurement Safeguards

Utilize secure payment mechanisms where feasible, especially for initial transactions. Prioritize suppliers offering product warranties and third-party inspection options (e.g., SGS, BV). Conduct sample testing under real-world load conditions before full-scale ordering. Assess responsiveness—sub-3-hour reply times correlate with proactive order management and after-sales service efficiency.

What Are the Best Switch Fuse Suppliers?

| Company Name | Location | Type | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization |

|---|---|---|---|---|---|---|---|---|

| Henan Longjian Electric Power Equipment Co., Ltd. | Henan, CN | Custom Manufacturer | Transformers, MV&HV Switchgear, Power Distribution Equipment | US $240,000+ | 100% | ≤3h | 20% | Yes (material, color, logo, packaging) |

| Asia Pacific Electrical Group Ltd. | Zhejiang, CN | OEM/ODM | Miniature Circuit Breakers, Fuses, Switch Disconnectors | US $1,000+ | 100% | ≤1h | - | Limited (model-specific variants) |

| Zhejiang Nalei Electric Co., Ltd. | Zhejiang, CN | Manufacturer | Fuses, Low Voltage Disconnectors, Circuit Breakers | US $70,000+ | 97% | ≤1h | 19% | Yes (design, labeling, configuration) |

| Yueqing Aidun Electric Co., Ltd. | Zhejiang, CN | Manufacturer | Fuses, Surge Protection Devices, Air Circuit Breakers | US $6,000+ | 100% | ≤6h | <15% | Standard models only |

| SUPERFINE INTERNATIONAL | Guangdong, CN | Trading Company | Industrial HRC Fuses, Inverters, Batteries | - | - | ≤6h | - | No customization data available |

Performance Analysis

Henan Longjian stands out for high-volume production capacity and robust customization options, backed by a 20% reorder rate and full on-time delivery record. Asia Pacific Electrical Group and Zhejiang Nalei demonstrate superior responsiveness (≤1h), critical for urgent procurement cycles. While both report strong delivery performance, Zhejiang Nalei offers broader engineering flexibility and higher transaction volume. Yueqing Aidun delivers consistent punctuality but has lower customer retention metrics, suggesting potential gaps in post-sale support or niche positioning. Caution is advised with trading companies like SUPERFINE INTERNATIONAL, which lack transparency on production control, quality assurance, and delivery history—factors vital for mission-critical electrical components.

FAQs

What certifications should switch fuse suppliers have?

Essential certifications include CE for EU compliance, CB Scheme recognition for global acceptance, and ISO 9001 for quality management. For specific markets, RoHS (environmental), CCC (China), or KTL (Korea) may apply. Always request valid test certificates from accredited laboratories covering rated current, insulation resistance, and short-circuit withstand capability.

What is the typical MOQ and pricing range?

MOQs vary from 1 piece (sample orders) to 500 pieces (bulk contracts). Pricing depends on amperage rating, pole configuration, and material quality. Basic NH-type fuse switches start at $0.80/unit, while heavy-duty HR17B-800 models reach $72.60/unit at 5-piece quantities. Volume discounts are common beyond 100 units.

Can switch fuses be customized?

Yes, leading manufacturers offer customization in housing material, color coding, branding (logo imprinting), terminal configuration, and packaging. Custom drawings and specifications are typically supported for OEM integration. Confirm tooling costs and NRE fees upfront for non-standard designs.

What are standard lead times?

Standard order fulfillment ranges from 15 to 30 days after deposit confirmation. Sample lead times are shorter—7 to 14 days. Expedited production may reduce timelines by 30%, subject to factory workload and component availability.

How to assess long-term supplier reliability?

Analyze reorder rates (ideally >15%), response consistency, and verified transaction history. Request references or case studies if available. For critical applications, conduct remote or on-site audits focusing on raw material traceability, assembly line controls, and final product testing protocols.