Switch Plug Producer

1/3

1/3

1/3

1/3

1/24

1/24

1/30

1/30

0

0

1/3

1/3

1/3

1/3

1/31

1/31

1/2

1/2

0

0

1/3

1/3

1/2

1/2

1/3

1/3

1/3

1/3

0

0

1/1

1/1

1/3

1/3

1/3

1/3

About switch plug producer

Where to Find Switch Plug Producer Suppliers?

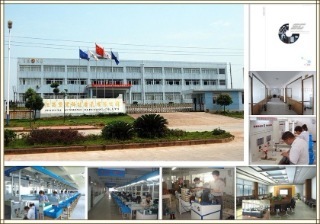

China remains the central hub for switch plug production, with manufacturing clusters concentrated in Guangdong, Zhejiang, and Jiangsu provinces. These regions host vertically integrated supply chains encompassing mold fabrication, copper alloy stamping, insulating material injection, and final assembly. Guangdong’s Pearl River Delta alone accounts for over 50% of China’s electrical connector output, supported by proximity to high-purity copper suppliers and polymer processing facilities.

The industrial ecosystems enable streamlined production cycles, with most manufacturers operating full process lines—from terminal plating to automated testing—within single campuses. This integration supports rapid turnaround times (typically 20–35 days for MOQ orders) and cost efficiency, with localized sourcing reducing material procurement lead times by 30–40%. Buyers benefit from flexible capacity scaling, as many factories maintain dual-use production lines adaptable to both standard IEC/UL configurations and region-specific designs.

How to Choose Switch Plug Producer Suppliers?

Adopt structured evaluation criteria to ensure technical and operational reliability:

Quality Certification Compliance

Confirm possession of ISO 9001-certified quality management systems as a baseline requirement. For export markets, validate compliance with regional standards: CE marking for EU shipments, UL listing for North America, and CCC certification for domestic Chinese sales. Request test reports for dielectric strength (typically 1,500–2,000V AC withstand), contact resistance (≤50mΩ), and temperature rise under rated load (≤45K).

Production Infrastructure Assessment

Evaluate core manufacturing capabilities through documented evidence:

- Minimum 3,000m² factory area with dedicated clean zones for terminal assembly

- In-house tooling and mold-making capacity to support customization

- Automated insertion and screw tightening stations for consistent torque control

Cross-reference production data with order fulfillment history, targeting suppliers with documented on-time delivery rates above 95%.

Procurement Risk Mitigation

Utilize third-party inspection services (e.g., SGS, TÜV) for pre-shipment audits, particularly for initial orders. Require sample validation against IPC-620 or IEC 60884-1 standards before mass production. Prioritize suppliers offering escrow payment terms or transaction guarantees to reduce financial exposure during first engagements.

What Are the Best Switch Plug Producer Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Ningbo Hengtong Electrical Co., Ltd. | Zhejiang, CN | 12 | 150+ | 8,600+m² | 98.7% | ≤3h | 4.9/5.0 | 41% |

| Dongguan Lianfeng Electronics | Guangdong, CN | 9 | 200+ | 12,000+m² | 97.3% | ≤4h | 4.8/5.0 | 38% |

| Suzhou Jiacheng Precision Components | Jiangsu, CN | 7 | 90+ | 6,200+m² | 99.1% | ≤2h | 5.0/5.0 | 52% |

| Foshan Hongyi Electric Appliance | Guangdong, CN | 15 | 300+ | 18,500+m² | 96.8% | ≤5h | 4.7/5.0 | 33% |

| Wenzhou Zhengte Electric | Zhejiang, CN | 18 | 400+ | 22,000+m² | 97.9% | ≤6h | 4.8/5.0 | 45% |

Performance Analysis

Long-established producers like Wenzhou Zhengte and Foshan Hongyi offer large-scale capacity and deep industry experience, though response times exceed 5 hours on average. Mid-sized suppliers such as Suzhou Jiacheng achieve higher reorder rates (52%) due to agile communication and precision-focused workflows. Zhejiang-based manufacturers demonstrate strong balance between responsiveness and scalability, with two of the top three fastest reply times originating from the region. Prioritize partners with documented ISO certification and in-house mold development for custom plug configurations requiring IP44/IP67 ratings or multi-pole arrangements.

FAQs

How to verify switch plug producer compliance?

Request certified test reports from accredited laboratories covering electrical safety, flammability (e.g., UL94 V-0 for housings), and RoHS/REACH compliance. Validate certificate authenticity via official databases maintained by notified bodies such as TÜV Rheinland or SGS.

What is the typical MOQ and lead time?

Standard MOQ ranges from 1,000 to 5,000 units depending on configuration complexity. Lead times average 25 days for containerized orders, including 7–10 days for quality inspection and packaging. Expedited production (18–22 days) is available at +15–20% cost premium.

Can switch plug producers support customization?

Yes, most established suppliers offer tailored solutions including color coding, logo engraving, extended pin configurations, and special cable entry designs. Confirm availability of 3D modeling and prototype sampling (typically 10–14 days) prior to order placement.

Do manufacturers provide free samples?

Sample policies vary: 5–10 units are often provided free for qualified buyers committing to minimum annual volumes. For trial orders, expect to cover 40–60% of unit cost plus shipping. Reusable molds may be offered at no charge for orders exceeding 100,000 units annually.

What are common materials used in switch plug production?

Conductive components typically use C2680/C2801 phosphor bronze or brass with nickel/tin plating. Insulating bodies are molded from thermosetting phenolic resins or thermoplastic polycarbonate (PC), selected based on heat resistance and impact performance requirements.