Tape Edge Machine Distributor

Top sponsor listing

Top sponsor listing

About tape edge machine distributor

Where to Find Tape Edge Machine Suppliers?

China remains the central hub for tape edge machine manufacturing, with key supplier clusters concentrated in Henan and Shandong provinces. These regions host vertically integrated industrial ecosystems specializing in textile, furniture, and mattress machinery production. Zhengzhou in Henan has emerged as a core center for mattress-specific tape edge sewing machines, supported by a dense network of component suppliers and skilled technical labor. Qingdao in Shandong focuses on woodworking and edge banding equipment, leveraging proximity to steel and automation supply chains to optimize production efficiency.

The regional specialization enables cost advantages of 20–30% compared to European or North American manufacturers, driven by localized sourcing of motors, drive systems, and control units. Integrated logistics infrastructure supports rapid export fulfillment, with average lead times ranging from 15 to 30 days for standard models. Buyers benefit from scalable production capacity, particularly for automated and semi-automatic configurations, with many suppliers offering modular designs adaptable to different material thicknesses and stitching patterns.

How to Choose Tape Edge Machine Suppliers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Expertise and Product Range

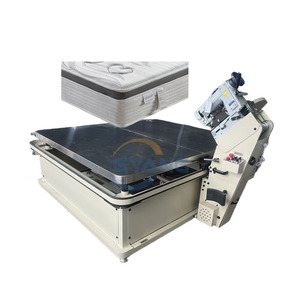

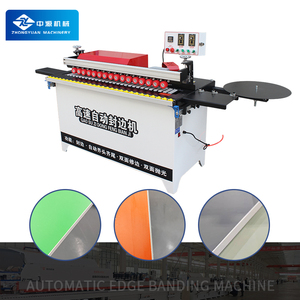

Assess whether the supplier specializes in the specific type of tape edge application—mattress border sewing, foam edge binding, or wood edge banding. Suppliers like Zhengzhou Kovi Machinery and Zhengzhou Yize Machinery focus on high-speed mattress tape edge sewing machines with chain-stitch or overlock capabilities, while Qingdao Zhongding Machinery targets woodworking applications with automatic edge banders. Verify product specifications including stitch rate (typically 1,000–2,500 rpm), motor power (1.5–3kW), and compatibility with materials such as polyurethane foam, cotton tape, or PVC edging.

Production and Customization Capability

Evaluate customization options critical for integration into existing production lines:

- Adjustable material size input (e.g., mattress widths from 700–2200mm)

- Configurable functions: pre-milling, glue application, trimming, polishing, end-corners sealing

- OEM/ODM support for branding (logo, color scheme, packaging label)

- In-house engineering teams capable of modifying feed mechanisms or control panels

Cross-reference customization claims with actual product listings and client feedback to confirm implementation consistency.

Quality Assurance and Transaction Security

Prioritize suppliers demonstrating consistent on-time delivery performance (>98%) and responsive communication (response time ≤4 hours). While formal certifications such as ISO 9001 are not explicitly stated in available data, consistent Trade Assurance participation and reorder rates above 15% indicate operational reliability. For international buyers, confirm compliance with electrical safety standards (CE marking preferred) and request test reports for insulation resistance, grounding continuity, and mechanical guarding.

What Are the Best Tape Edge Machine Suppliers?

| Company Name | Specialization | Main Products (Listings) | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Key Features |

|---|---|---|---|---|---|---|---|

| Ningbo Jiangbei Esun Machinery Co., Ltd. | Foam & Furniture Machinery | Foam Machinery (101), Quilting Machines (62) | 100% | ≤20h | - | - | Broad industrial machinery portfolio; limited response speed |

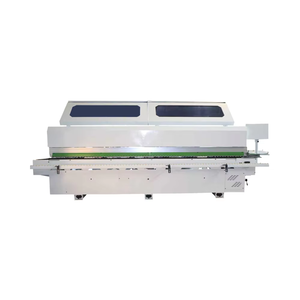

| Qingdao Zhongding Machinery Co., Ltd. | Wood Edge Banding | Automatic Edge Banders, Cold Press Machines | 100% | ≤3h | 18% | US $550,000+ | Italy-style designs; full customization including hydraulic pre-milling and corner trimming |

| Zhengzhou Kovi Machinery Co., Ltd. | Mattress Tape Edge Sewing | Tape Edge Sewing Machines, Quilting Equipment | 100% | ≤4h | 17% | US $180,000+ | Competitive pricing ($1,550–$1,800 range); strong focus on mattress production lines |

| Henan Joconn Machinery Co., Ltd. | Multifunctional Mattress Closing Systems | Mattress Edge Stitching, Chain-Stitch Binding | 100% | ≤3h | 20% | US $110,000+ | High customization flexibility; wide price band ($3,000–$6,000) |

| Zhengzhou Yize Machinery Co., Ltd. | Automatic Mattress & Quilt Edging | Overlock Tape Edge, Portable Sewing Units | 98% | ≤2h | 29% | US $450,000+ | Highest reorder rate; fast response; diverse output from $498 entry-level to $5,000+ premium models |

Performance Analysis

Zhengzhou Yize Machinery stands out with the highest reorder rate (29%) and fastest average response time (≤2h), indicating strong customer satisfaction and service agility. Qingdao Zhongding offers advanced woodworking solutions with extensive functional customization, suitable for buyers integrating edge banding into CNC-based furniture workflows. For mattress manufacturers, Henan-based suppliers dominate the segment—Kovi and Joconn provide competitive pricing and scalability, with Joconn offering higher-end multifunctional systems. Despite slightly lower online revenue, all top-tier suppliers maintain 100% on-time delivery except Yize (98%), which still falls within acceptable thresholds for industrial procurement.

FAQs

How to verify tape edge machine supplier reliability?

Analyze verified transaction metrics: prioritize suppliers with documented on-time delivery ≥98%, reorder rates >15%, and response times under 4 hours. Request reference clients or third-party inspection reports if available. Validate machine performance through video demonstrations of live operation and stitch quality testing.

What is the typical MOQ and lead time?

Minimum order quantity is typically 1 set for standard models. Lead time ranges from 15 to 25 days after deposit confirmation, depending on customization level. Express production may be available for urgent orders at additional cost.

Can suppliers customize voltage and control systems?

Yes, most suppliers offer dual-voltage configurations (e.g., 220V/380V, 50Hz/60Hz) and can integrate PLC controls or foot pedal interfaces upon request. Confirm IEC-standard compliance for electrical components prior to order finalization.

Do suppliers provide installation support or training?

Limited post-delivery support is standard. Some suppliers offer basic instructional videos or remote guidance via chat. On-site technician deployment is rare unless contracted separately. Buyers should plan for local technical staffing or third-party commissioning services.

Are spare parts and after-sales service available?

Spare parts such as needles, presser feet, belts, and servo motors are generally available upon request. However, formal warranty terms (typically 12 months) often exclude consumables. Long-term service depends on buyer-supplier relationship continuity and inventory planning.