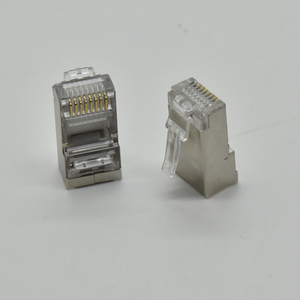

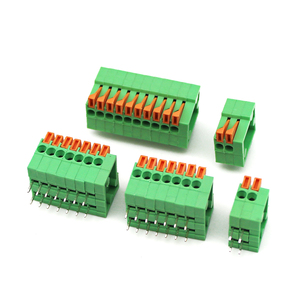

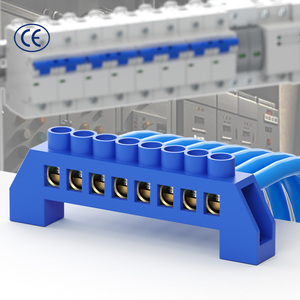

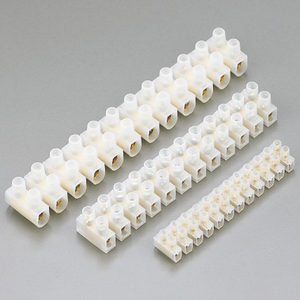

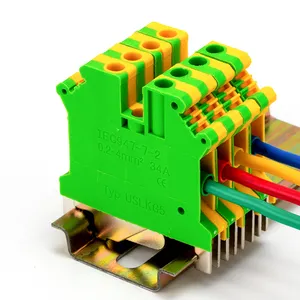

Terminalblock

Top sponsor listing

Top sponsor listing

1/3

1/3

1/52

1/52

1/48

1/48

1/25

1/25

1/10

1/10

1/5

1/5

1/33

1/33

1/10

1/10

0

0

1/33

1/33

1/3

1/3

0

0

1/9

1/9

1/8

1/8

1/26

1/26

1/32

1/32

1/11

1/11

0

0

1/19

1/19

About terminalblock

Where to Find Terminal Block Suppliers?

China remains the central hub for terminal block manufacturing, with key production clusters in Guangdong, Hubei, and Fujian provinces driving global supply. Shenzhen and Dongguan in Guangdong province host advanced electronics component ecosystems, enabling rapid prototyping and high-volume output for PCB, DIN rail, and pluggable terminal blocks. Hubei’s manufacturing base specializes in industrial-grade insulating materials, supporting cost-efficient production of thermoplastic housings used in power distribution applications.

These regions benefit from vertically integrated supply chains—spanning mold fabrication, copper alloy stamping, and surface treatment processes—reducing lead times by 20–35% compared to offshore alternatives. Suppliers leverage localized access to raw materials such as PA66 nylon, brass contacts, and tin-plated phosphor bronze, ensuring consistent material traceability. Average monthly production capacities range from 500,000 to over 2 million units per facility, with standard lead times averaging 15–25 days for MOQ-compliant orders. Export-ready infrastructure supports shipments to North America, Europe, and Southeast Asia, with most suppliers experienced in compliance documentation for international markets.

How to Choose Terminal Block Suppliers?

Selecting reliable partners requires a structured evaluation across technical, operational, and transactional dimensions:

Quality & Compliance Verification

Confirm adherence to international standards including IEC 60947 (low-voltage terminals), UL 1059 (terminal blocks), and RoHS/REACH for hazardous substances. CE marking is essential for European market access, while UL recognition enhances acceptance in North American electrical systems. Request test reports on dielectric strength (typically 2,500–6,000V AC), temperature resistance (up to 130°C), and flame rating (UL94 V-0).

Production & Customization Capability

Assess supplier flexibility through the following criteria:

- In-house tooling and molding facilities for custom housing geometries

- Capacity to modify contact configurations (pin count, pitch spacing, wire gauge compatibility)

- Surface labeling, laser marking, color coding, and packaging customization options

Prioritize manufacturers offering full design-to-production workflows, particularly for specialized variants such as angled PCB headers, shielded blocks, or waterproof IP66/IP69K-rated enclosures.

Performance Metrics & Transaction Security

Analyze verified performance indicators: target on-time delivery rates ≥95%, response times under 5 hours, and reorder rates above 15% as proxies for customer satisfaction. Favor suppliers with documented quality management systems (e.g., ISO 9001) and participation in third-party inspection programs. Use secure payment escrow mechanisms until product verification at destination, especially for first-time engagements.

What Are the Best Terminal Block Suppliers?

| Company Name | Main Products | Customization Options | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order (Pieces) | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Westsam Technology (Shenzhen) Co., Ltd. | Connectors, EV Connectors, Terminals, Power Cables | Color, cable length, pins, label, connector type, mounting size, material, logo, moldable design, angled socket, PCB contact dimensions | US $160,000+ | 100% | ≤1h | <15% | 50 | $0.07–0.13 |

| Xiamen Leaka Electrical Equipment Co., Ltd. | Terminal Blocks, Waterproof Connectors, Subsea Solutions | Color, material, size, logo, packaging, label, graphic | US $330,000+ | 100% | ≤1h | 17% | 100 | $0.06–14.99 |

| Hubei Wanta Plastic Co., Ltd. | Industrial Terminal Blocks, Shielding Blocks, Battery Lugs | Color, material, size, logo, packaging, label, graphic | US $80,000+ | 100% | ≤1h | 16% | 100 | $0.02–0.12 |

| Zhongshan Hongyue Lighting Electrical Appliance Factory | Terminal Blocks, Cable Glands, Connectors | Limited customization reported | US $30,000+ | 100% | ≤5h | 22% | 500 | $0.01–0.13 |

| Dongguan Aosi Electronics Co., Ltd. | PCB Terminal Blocks, Spring Terminals, Pluggable Connectors | Color, size, logo, packaging, label, specifications, dimensions | US $20,000+ | 88% | ≤3h | 18% | 10 poles / 100 pieces | $0.04–$10.00 |

Performance Analysis

Westsam Technology and Xiamen Leaka demonstrate strong technical agility with extensive customization capabilities and sub-1-hour response times, making them ideal for complex or time-sensitive procurement. Xiamen Leaka stands out for high-value niche products, including IP69K-rated underwater connectors priced up to $67/set. Hubei Wanta offers the lowest price points starting at $0.02/unit, suitable for high-volume industrial deployments. Zhongshan Hongyue achieves a high reorder rate (22%), indicating solid customer retention despite limited customization visibility. Dongguan Aosi provides flexible pole-based ordering but exhibits lower on-time delivery performance (88%), suggesting potential fulfillment risks for urgent timelines. Buyers should prioritize suppliers with 100% on-time delivery records and robust customization frameworks for mission-critical applications.

FAQs

How to verify terminal block supplier reliability?

Cross-check claimed certifications (CE, RoHS, UL) with official databases or request copies of test reports from accredited labs. Conduct virtual factory audits to assess production lines, inventory management, and QC procedures. Review transaction history for consistency in order fulfillment and dispute resolution.

What is the typical MOQ and pricing structure?

Standard MOQs range from 50 to 1,000 pieces depending on complexity. Prices vary significantly: basic screw-type blocks start at $0.01–0.05/unit, while compact lever-nut or waterproof models reach $0.35+; high-spec connectors can exceed $50/set. Volume discounts are commonly available beyond 10,000 units.

Can suppliers provide free samples?

Most suppliers offer samples for evaluation, often waiving fees for qualified buyers committing to future volume orders. Expect to pay partial or full sample costs for highly customized or high-value configurations. Shipping charges typically apply unless otherwise negotiated.

What customization options are available?

Common customization includes contact material (brass, phosphor bronze), wire gauge compatibility (AWG 14–28), insulation color, laser engraving, special labeling, modular stacking, and mounting styles (DIN rail, panel mount). Full OEM branding—including custom molds—is supported by manufacturers with in-house tooling capabilities.

How to ensure quality control during mass production?

Implement pre-shipment inspections (PSI) using third-party agencies like SGS or TÜV. Define clear AQL (Acceptable Quality Level) thresholds—commonly 0.65 for critical defects. Request batch-specific test data on continuity, insulation resistance, and mechanical durability prior to shipment.