Tetrapack Automatic Packing Machine Distributor

Top sponsor listing

Top sponsor listing

1/23

1/23

1/10

1/10

1/7

1/7

1/24

1/24

1/10

1/10

1/14

1/14

1/27

1/27

About tetrapack automatic packing machine distributor

Where to Find Tetrapack Automatic Packing Machine Distributors?

China remains the global epicenter for automated packaging machinery, with key supplier clusters concentrated in Fujian and Shandong provinces. Quanzhou, Fujian, hosts a specialized ecosystem for flexible packaging systems, where over 70% of local manufacturers focus on liquid and powder filling solutions compatible with Tetra Pak-style cartons. Qingdao, Shandong, leverages its proximity to steel and automation component suppliers to produce integrated packaging lines at reduced material costs—achieving up to 18% lower production expenses compared to EU-based competitors.

These industrial hubs offer vertically aligned supply chains, enabling rapid prototyping and scalable production. Facilities typically integrate CNC machining, robotic assembly, and conveyor integration under one roof, supporting lead times of 25–40 days for standard configurations. Buyers benefit from localized access to sealing units, film feed systems, and control panels, minimizing dependency on external vendors. The region’s logistics infrastructure supports efficient containerized shipping via Xiamen and Qingdao ports, with established export channels to Southeast Asia, Europe, and North America.

How to Choose Tetrapack Automatic Packing Machine Suppliers?

Evaluating suppliers requires a structured assessment across technical, operational, and transactional dimensions:

Technical Compliance & Certification

Confirm adherence to international safety and quality benchmarks. ISO 9001 certification is a baseline indicator of consistent manufacturing processes. For exports to regulated markets (EU, USA), verify CE marking and compliance with machinery directives. Review documentation for electrical components (e.g., PLCs, HMI interfaces) and mechanical safety guards.

Production and Customization Capability

Assess core competencies through the following criteria:

- Proven ability to customize machine parameters: bag size, fill volume, sealing type (three-side, four-side, plug seal), and integration with upstream/downstream equipment

- In-house engineering teams capable of providing CAD layouts, material flow diagrams, and control system schematics

- Support for multi-language HMI panels, nitrogen flushing, date coding, and labeling integration

- Experience with food-grade materials (SUS-304 stainless steel) and hygienic design standards

Cross-reference customization claims with product listings showing diverse configurations—from small-scale liquid sachet machines ($398–$498 range) to high-capacity granule packing systems exceeding $8,500.

Performance Metrics and Transaction Security

Prioritize suppliers with verifiable performance records:

- On-time delivery rate ≥98%

- Response time ≤2 hours for initial inquiries

- Reorder rate >20%, indicating customer retention

- Minimum online revenue transparency (e.g., US $100,000+ annual turnover)

Utilize secure payment mechanisms such as escrow services and request sample testing before full-order commitment. Insist on video demonstrations of machine operation and factory walkthroughs to validate production capacity.

What Are the Top Tetrapack Automatic Packing Machine Suppliers?

| Company Name | Location | Verified Type | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Key Product Range | Customization Scope |

|---|---|---|---|---|---|---|---|---|

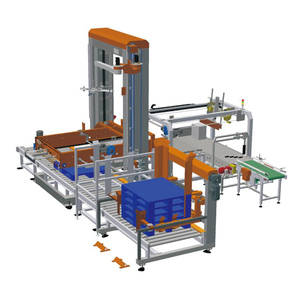

| Qingdao Ausense Packing Equipment Co., Ltd. | Shandong, CN | Custom Manufacturer | 100% | ≤2h | 21% | US $1,200,000+ | Packaging Lines, Wrapping, Sealing, Conveyors | Pallet size, robotic arm, strapping, label, layout |

| Quanzhou Qianshou Mechanical Equipment Co., Ltd. | Fujian, CN | Custom Manufacturer | 100% | ≤2h | 27% | US $110,000+ | Doypack, Liquid, Snack Packaging Machines | Color, material, logo, packaging label, graphic |

| Quanzhou Huapai Machinery Co., Ltd. | Fujian, CN | Custom Manufacturer | 98% | ≤2h | 17% | US $210,000+ | Liquid, Powder, Food, Filling & Seal Machines | Bag dimensions, film width, speed, language, automation |

| Liaoyang Pharma Machinery Imp. & Exp. Co., Ltd. | Liaoning, CN | Multispecialty Supplier | 72% | ≤3h | 33% | US $110,000+ | Teabag, Powder, Liquid Vertical Packers | Material, size, color, label, logo |

| Xinxiang Chenwei Machinery Co., Ltd. | Henan, CN | Multispecialty Supplier | 100% | ≤2h | <15% | US $240,000+ | Granule, Sauce, Liquid, Multifunction Pouch Machines | Belt, sensor, inner/outer bag, signage, weight |

Performance Analysis

Qingdao Ausense stands out with the highest reported online revenue and comprehensive system integration capabilities, making it suitable for turnkey packaging line installations. Quanzhou Qianshou demonstrates strong customer retention (27% reorder rate) and responsiveness, ideal for buyers requiring iterative design collaboration. Despite lower on-time delivery (72%), Liaoyang Pharma Machinery shows the highest reorder rate (33%), suggesting strong post-sale satisfaction in niche applications like liquid seasoning and pharmaceutical packaging. Xinxiang Chenwei offers robust engineering depth with high stainless steel content and advanced weighing systems, though its lower reorder rate may indicate market positioning challenges. Fujian-based suppliers excel in liquid and flexible pouch applications, while Shandong and Henan manufacturers provide broader material handling integration.

FAQs

How to verify tetrapack automatic packing machine supplier reliability?

Validate certifications (ISO 9001, CE) through official registries. Request factory audit reports or video tours confirming CNC facilities, assembly lines, and QC stations. Analyze transaction history, focusing on on-time delivery consistency and dispute resolution outcomes.

What is the typical minimum order quantity (MOQ) and lead time?

Standard MOQ is 1 set across suppliers, enabling low-volume procurement for testing. Lead times range from 20–40 days depending on customization level. Simple modifications (label placement, voltage adjustment) add ≤5 days; full custom designs (new sealing heads, robotic integration) may extend timelines to 60 days.

Can suppliers customize machines for specific packaging formats?

Yes, most suppliers support extensive customization including bag type (stand-up pouch, spouted pouch), seal configuration (three-side, plug, zipper), film thickness (up to 120μm), and integration with nitrogen flushing or date printing. Provide detailed specifications including dimensions, material type, and production speed requirements.

Do suppliers offer technical support and installation assistance?

Leading manufacturers provide remote commissioning support via video guidance. Some offer on-site installation services at additional cost. Ensure availability of English manuals, wiring diagrams, and spare parts lists before purchase. Post-warranty service agreements should be clarified upfront.

What are common payment and shipping terms?

Payment terms typically include T/T (30% deposit, 70% before shipment) or Trade Assurance-backed transactions. Shipping options include FOB (port of origin) or CIF (destination port). Sea freight is standard for full-container loads; air freight is viable for urgent single-machine deliveries.