The Factory Automation

CN

CN

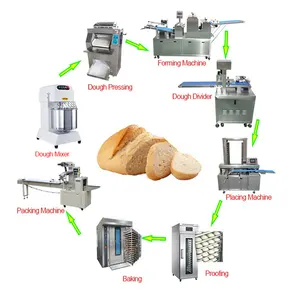

About the factory automation

Where to Find Factory Automation Equipment Suppliers?

China remains the global epicenter for factory automation equipment manufacturing, with key industrial hubs in Guangdong, Henan, and Dongguan driving innovation and cost efficiency. The Pearl River Delta region, particularly Shenzhen and Dongguan, hosts advanced electronics and intelligent manufacturing clusters specializing in automated assembly lines and robotics. Meanwhile, Henan’s Zhengzhou has emerged as a center for bulk material processing automation, leveraging regional logistics advantages and mature supply chains for packaging, mixing, and conveying systems.

These regions offer vertically integrated production ecosystems where component sourcing, machining, system integration, and testing occur within compact geographic zones. This integration enables lead times as short as 30 days for standard configurations and supports rapid prototyping for customized automation solutions. Buyers benefit from 20–35% lower unit costs compared to equivalent Western or Southeast Asian suppliers, driven by economies of scale, localized labor pools, and streamlined regulatory pathways for export.

How to Choose Factory Automation Equipment Suppliers?

Selecting reliable partners requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & System Integration

Verify adherence to international standards such as ISO 9001 for quality management and CE marking for electrical safety compliance. For automation systems involving robotics or high-voltage components, confirm EMC and RoHS certifications. Request detailed schematics and control logic documentation—especially PLC programming platforms (e.g., Siemens, Allen-Bradley)—to ensure compatibility with existing factory infrastructure.

Production Capability Assessment

Evaluate supplier capacity based on tangible metrics:

- Facility size exceeding 3,000m² indicating scalable operations

- In-house engineering teams capable of custom design and simulation (e.g., CAD/3D modeling)

- Integrated testing bays for full-line dry runs before shipment

Cross-reference claimed capabilities with on-time delivery performance (target ≥95%) and evidence of past project deployments.

Customization & Quality Assurance

Confirm scope of customization—including line speed, product handling specifications, material compatibility, and integration with MES/SCADA systems. Prioritize suppliers offering pre-shipment FAT (Factory Acceptance Testing) reports and video validation. Analyze response time (<2 hours ideal) and reorder rates (<15% suggests niche specialization or limited client retention).

What Are the Leading Factory Automation Equipment Suppliers?

| Company Name | Location | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

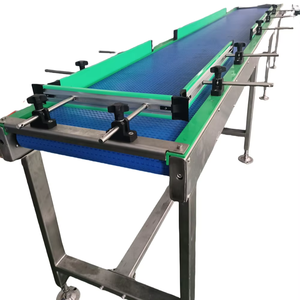

| Zhengzhou Hongdi Machinery Co., LTD. | Henan, CN | Mixing Equipment, Multi-Function Packaging Machines, Assembly Line | $3,197–6,626 | 1 set | 100% | ≤2h | US $70,000+ | <15% |

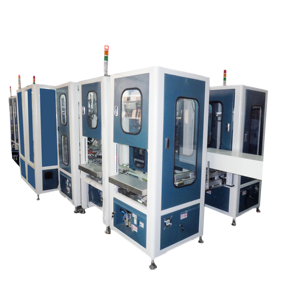

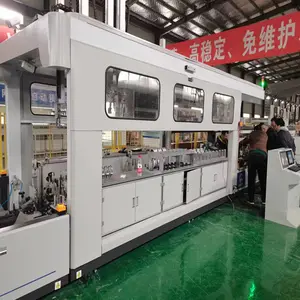

| Dongguan Yicheng Automation Equipment Co., Ltd. | Dongguan, CN | Electronics Production Machinery, Assembly Line, Circuit Breaker Automation | $24,000–120,000 | 1 set / 1 acre | 100% | ≤7h | Data not available | Not specified |

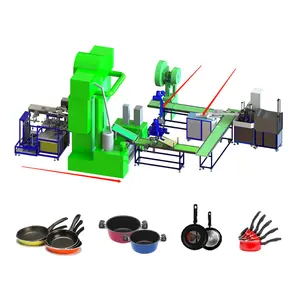

| Guangdong Huazhe Intelligent Manufacturing Co., Ltd. | Guangdong, CN | Automatic Coating, Spraying, Battery Module Pack Systems | $1,000–1,500 | 1 set/piece | 33% | ≤2h | US $20,000+ | <15% |

| Qingzhou Lude Automation Equipment Co., Ltd. | Shandong, CN | Filling Machines, Water Treatment Machinery | $4,999–8,999 | 1 set | 100% | ≤1h | US $1,000+ | <15% |

| Shenzhen Qihang Electronics Co., Ltd. | Shenzhen, CN | Electrophoresis Lines, Paint Coating, Plating Equipment | $25,500–36,000 | 1 piece | 100% | ≤2h | US $270,000+ | <15% |

Performance Analysis

Zhengzhou Hongdi and Qingzhou Lude demonstrate strong reliability with 100% on-time delivery and competitive pricing for food, chemical, and agricultural processing lines. Dongguan Yicheng specializes in high-value industrial automation, offering large-scale electronic and gearbox assembly systems priced above $100,000, indicating advanced engineering capacity. Shenzhen Qihang leads in surface treatment automation, supported by extensive customization options and the highest reported online revenue, reflecting robust export activity. Notably, Guangdong Huazhe shows fast responsiveness but low on-time delivery (33%), suggesting potential fulfillment risks despite flexible customization. Buyers seeking turnkey solutions should prioritize suppliers with documented project experience and verifiable client references.

FAQs

How to verify factory automation supplier credibility?

Cross-check certifications through official registries and request audit trails for quality control processes. Demand video walkthroughs of active production lines and recent client installations. Review transaction history, focusing on dispute resolution records and consistency in delivery performance.

What is the typical lead time for automated production lines?

Standard systems require 30–45 days from order confirmation. Customized lines with PLC programming, robotic integration, or special material handling extend to 60–90 days. Add 10–20 days for international shipping depending on destination and mode.

Do suppliers support OEM and ODM services?

Yes, most suppliers listed offer full customization including branding, control interface localization, dimensional adjustments, and integration with existing SCADA/MES networks. Minimum order quantities typically remain at one set, though tooling charges may apply for bespoke designs.

Are samples available for factory automation equipment?

Full-system sampling is uncommon due to size and complexity. However, suppliers often provide subsystem demonstrations (e.g., filling head operation, conveyor tracking) via video or remote inspection. Some offer modular component testing upon request.

What are common payment and delivery terms?

Standard terms include 30% advance payment with balance before shipment. Escrow services are recommended for first-time transactions. FOB terms are prevalent; CIF can be arranged for large orders. Confirm packaging standards (wooden crates, moisture protection) and insurance coverage prior to dispatch.