Three Phase Servo Voltage Stabilizer

Top sponsor listing

Top sponsor listing

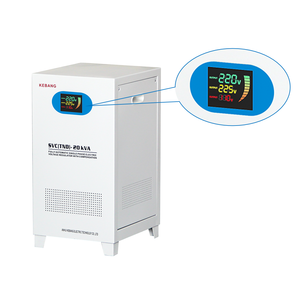

About three phase servo voltage stabilizer

Where to Find Three Phase Servo Voltage Stabilizer Suppliers?

China remains the dominant manufacturing hub for three phase servo voltage stabilizers, with key production clusters concentrated in Zhejiang, Guangdong, and Anhui provinces. These regions host vertically integrated supply chains encompassing copper winding fabrication, core lamination, control circuit assembly, and final testing—enabling efficient production scaling. Dongguan and Yueqing serve as primary centers for low-to-medium power units (5–100 kVA), leveraging proximity to component suppliers and export ports. Anhui and Wenzhou have emerged as cost-competitive sources for high-capacity industrial models (up to 150 kVA), supported by localized transformer manufacturing ecosystems.

The industrial clusters offer buyers economies of scale, with many facilities operating automated coil winding lines and CNC-cut laminations that reduce material waste by 12–18%. Lead times for standard configurations typically range from 15–30 days, while customized units require 30–45 days. Export-ready logistics networks enable direct container loading for bulk orders, with FOB pricing commonly available for global shipments. The integration of online sales channels has increased price transparency, allowing procurement teams to compare technical specifications and transaction metrics across multiple suppliers efficiently.

How to Choose Three Phase Servo Voltage Stabilizer Suppliers?

Procurement decisions should be guided by structured evaluation criteria focusing on technical capability, quality assurance, and transaction reliability:

Technical & Design Capabilities

Verify supplier expertise in servo-controlled regulation systems, including response time (typically 10–50ms), input voltage range (±15% to ±50%), and output accuracy (±1–3%). Confirm availability of both TNS/SVC and SBW series designs for different load types. For industrial applications, ensure compliance with IEC 61000-4-30 power quality standards. Suppliers with in-house PCB design and motorized variac assembly demonstrate greater control over performance consistency.

Production Infrastructure Assessment

Evaluate operational scale and process control through the following indicators:

- Minimum factory area exceeding 3,000m² for stable batch production

- In-house copper winding and toroidal/core-type transformer assembly

- Automated calibration stations with load simulation testing (resistive/inductive)

- Dedicated R&D or engineering support for custom voltage ranges or enclosure types

Cross-reference these capabilities with on-time delivery rates above 95% and response times under 5 hours to assess operational responsiveness.

Quality Management & Transaction Security

Prioritize suppliers with documented quality management systems (ISO 9001 preferred). While CE marking is frequently listed, request test reports validating EMC and dielectric strength (IEC 61000-4-4 surge, IEC 61000-4-5 ESD). Use secure payment mechanisms such as trade assurance or escrow services, especially for first-time transactions. Request sample units to verify build quality, cooling efficiency, and noise levels (ideally below 55 dB at 1m distance) before full-scale ordering.

What Are the Best Three Phase Servo Voltage Stabilizer Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Sample MOQ | Key Strengths |

|---|---|---|---|---|---|---|---|

| Anhui Pinkong Energy Technology Co., Ltd. | Voltage Regulators/Stabilizers, Inverters | US $160,000+ | 98% | ≤1h | <15% | 1 set | Customization options (color, logo, packaging); strong export volume |

| Zhejiang Kaiyi Electric Co., Ltd. | Voltage Regulators/Stabilizers, ATS, MCBs | US $30,000+ | 100% | ≤1h | 20% | 1 set | Broad product line; high-power SBW series up to 150kVA |

| Dongguan Kunmai Power Supply Co., Ltd. | Voltage Regulators/Stabilizers, Transformers | US $8,000+ | 100% | ≤1h | <15% | 1 piece | Specialized in voltage regulation; consistent delivery performance |

| Yueqing Zhongming Electric Co., Ltd. | Voltage Regulators/Stabilizers, Solar Controllers | US $3,000+ | 100% | ≤5h | <15% | 1 piece | Competitive pricing; copper-wound models from $150 |

| Wenzhou Wenyu Electric Co., Ltd. | Transformers, Voltage Regulators/Stabilizers | US $6,000+ | 75% | ≤3h | 16% | 1 piece | Diverse TNS/SVC series; lower-cost entry point models |

Performance Analysis

Anhui Pinkong leads in customization and transaction volume, offering tailored branding and packaging—ideal for distributors seeking private-label solutions. Zhejiang Kaiyi distinguishes itself with high-power industrial models and flawless delivery records, making it suitable for mission-critical installations. Dongguan Kunmai and Yueqing Zhongming deliver reliable performance with fast response times, though their lower reorder rates suggest limited post-sale engagement. Wenzhou Wenyu offers budget-friendly options but exhibits a significantly lower on-time delivery rate (75%), indicating potential fulfillment risks. Buyers prioritizing uptime should favor suppliers with ≥98% on-time delivery and in-house transformer production.

FAQs

What certifications should a reliable stabilizer supplier have?

At minimum, ISO 9001 for quality management. CE marking is common, but verify through test reports rather than self-declaration. For regulated markets, confirm compliance with local standards such as UL 1310 (North America) or BS EN 61558 (UK/EU).

What is the typical MOQ and lead time?

Standard MOQ is 1 unit for sample testing, with bulk discounts starting at 5–10 units. Lead time averages 15–20 days for stock models and 30–45 days for custom configurations involving specific voltages or enclosures.

Can three phase servo stabilizers be customized?

Yes. Common modifications include input/output voltage ranges (e.g., 220V to 380V conversion), IP-rated enclosures (IP20–IP55), analog/digital meters, bypass switches, and OEM labeling. Suppliers like Anhui Pinkong explicitly list color, logo, and packaging customization.

What materials are used in core components?

High-efficiency models use 100% copper windings and grain-oriented silicon steel cores. Avoid aluminum-wound transformers for loads exceeding 20kVA due to thermal limitations. Confirm material type in product descriptions or request material certificates.

How to validate supplier claims before ordering?

Request product test videos under load conditions, factory tour links, or third-party inspection reports. Conduct sample testing for regulation accuracy, temperature rise, and harmonic distortion. Use incremental order scaling—start with a single unit before committing to container loads.