Tile Maker

Top sponsor listing

Top sponsor listing

CN

CN

1/19

1/19

CN

CN

1/19

1/19

1/11

1/11

1/14

1/14

1/14

1/14

CN

CN

1/18

1/18

1/11

1/11

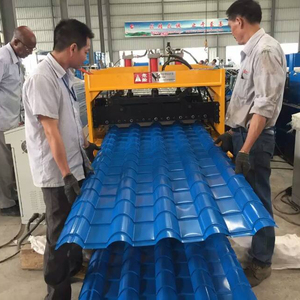

About tile maker

Where to Find Tile Maker Suppliers?

China remains the global epicenter for tile making equipment manufacturing, with key production clusters concentrated in Hebei, Henan, and Jiangsu provinces. These regions host vertically integrated industrial ecosystems that support rapid prototyping, mass production, and export logistics. Cangzhou in Hebei Province is particularly notable for its specialization in cold roll forming technology used in roofing and wall tile machinery, enabling high-precision profile shaping with PLC-controlled automation. Henan’s Gongyi City leverages decades of metallurgical expertise to produce robust hydraulic systems for concrete and terrazzo tile makers, while Nanjing in Jiangsu has emerged as a hub for advanced ceramic and clay-based tile machinery with strong R&D capabilities.

The clustering effect allows suppliers to maintain tight control over supply chains—from raw material sourcing to final assembly—reducing lead times by up to 30% compared to decentralized operations. Facilities typically operate within 5–10km proximity to component manufacturers (e.g., roller stations, hydraulic decoilers, air compressors), ensuring efficient maintenance and replacement cycles. Buyers benefit from scalable output options, with standard machine delivery timelines averaging 25–40 days depending on customization level. Localized production also enables cost advantages: labor and overhead expenses are 18–25% lower than comparable Western manufacturers, translating into competitive pricing without sacrificing technical performance.

How to Choose Tile Maker Suppliers?

Selecting reliable tile maker suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certifications

Verify ISO 9001 certification as a baseline indicator of quality management systems. For exports to regulated markets (EU, North America), confirm CE marking compliance covering electrical safety, mechanical stability, and noise emissions. Request documentation on core components such as PLC controllers (Siemens or Mitsubishi preferred), hydraulic pumps, and motor specifications. Suppliers using cold roll bending technology should provide material thickness tolerance data (typically ±0.1mm) and coil width compatibility ranges (commonly 800–1250mm).

Production Capability Assessment

Evaluate infrastructure maturity through verifiable metrics:

- Minimum factory area exceeding 3,000m² for sustained volume output

- In-house engineering teams capable of custom design modifications (e.g., graphic hole patterns, triple-layer door frame integration)

- On-site CNC machining, welding, and roller station calibration facilities

Cross-reference these capabilities with on-time delivery rates—suppliers achieving 100% punctuality across multiple fiscal periods demonstrate process reliability. Prioritize those offering digital design submissions (CAD/DWG) and simulation testing prior to fabrication.

Customization & After-Sales Support

Confirm scope of customization including color coating options, logo embossing, sheet-metal peak configurations, and automatic stacking systems. Assess after-sales responsiveness via average reply time (sub-4-hour responses indicate dedicated customer service). Reorder rate above 35% suggests customer satisfaction and product durability. Ensure suppliers offer remote troubleshooting support and spare parts availability for critical wear components like rollers and cutting blades.

What Are the Best Tile Maker Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Customization Options | Notable Features |

|---|---|---|---|---|---|---|---|

| Cangzhou Zhongtuo International Trade Co., Ltd. | Tile Making Machinery, Steel Frame Machines, Pipe Making Machinery | US $4,700,000+ | 100% | ≤2h | 37% | Yes | Hydraulic decoiler, PLC control, multi-layer coil processing, full-line automation |

| Nanjing Brickmac Engineering Co., Ltd. | Clay Tile Machines, Interlocking Tile Molding Systems | US $30,000+ | 100% | ≤4h | 50% | Yes | Color/material/size customization, packaging labeling, graphic shaping |

| Hubei Tengcang Building Materials Technology Co., Ltd. | 3D Ceramic Tiles, Porcelain Flooring Equipment | Not specified | 100% | ≤2h | Not available | Limited | 3D printing integration, polished porcelain finishing, new design models |

| Henan Dingxie Machinery Co., Ltd. | Terrazzo Tile Machines, Manual Clay Tile Presses | US $10,000+ | 60% | ≤1h | 100% | No | Low-cost entry models, manual operation variants, mortar mixing integration |

| Henan Province Gongyi City East China Metallurgical Coal Mine Machinery Factory | Concrete Terrazzo Machines, Full-Automatic Tile Presses | Not specified | 100% | ≤6h | Not available | No | High-capacity output, Italy-inspired designs, complete line solutions |

Performance Analysis

Cangzhou Zhongtuo leads in scalability and technological breadth, offering comprehensive automation packages suitable for large-scale construction material producers. Nanjing Brickmac stands out with the highest reorder rate (50%) and strong customization capacity, indicating consistent buyer retention and adaptability to niche requirements. Hubei Tengcang focuses on aesthetic innovation with 3D-printed ceramic solutions priced at $11,000–$11,600 per set, targeting premium interior markets. In contrast, Henan Dingxie offers budget-friendly alternatives starting below $600 per unit but reports only 60% on-time delivery, signaling potential logistical risks despite excellent post-purchase loyalty. The absence of detailed revenue data for three suppliers underscores the need for direct financial verification during due diligence.

FAQs

How to verify tile maker supplier reliability?

Validate certifications through official registries and request third-party audit reports detailing production workflows and quality inspections. Analyze transaction history, focusing on consistent on-time delivery records (>95%) and response efficiency. Conduct video audits of factory floors to assess CNC machining, roller calibration, and final assembly lines.

What is the typical MOQ and lead time?

Standard minimum order quantity is 1 set for automated systems and 5 sets for manual models. Lead times range from 20–45 days post-deposit, depending on complexity. Customized machines with PLC programming or special mold designs may require additional 10–15 days.

Do suppliers offer customization for tile profiles?

Yes, leading suppliers support dimensional adjustments (length, width, thickness), surface graphics, and structural features like interlocking edges or drainage holes. Custom roller dies take 7–10 days to manufacture, with tooling costs ranging from $800–$2,000 depending on intricacy.

Can tile making machines be shipped globally?

All listed suppliers export internationally. Confirm Incoterms (FOB, CIF) and ensure compliance with destination regulations for electrical and mechanical equipment. Sea freight is standard for full-container loads; air shipping is viable only for compact or spare-part orders.

Is sample testing recommended before bulk purchase?

Essential. Request live demonstrations or factory-produced samples to evaluate output consistency, noise levels, and material waste ratios. Benchmark against industry standards such as ASTM C39 for compressive strength in concrete tiles or ISO 10545 for ceramic finish durability.