Timer 24 Min

1/24

1/24

1/2

1/2

1/3

1/3

1/3

1/3

1/3

1/3

1/11

1/11

1/3

1/3

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/23

1/23

About timer 24 min

Where to Find Timer 24 Min Suppliers?

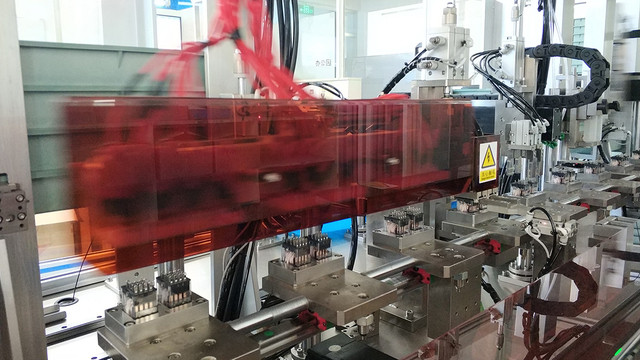

China accounts for over 75% of global electronic timer manufacturing, with concentrated production hubs in Guangdong and Zhejiang provinces. Guangdong—particularly Shenzhen and Dongguan—hosts the highest density of electronics OEMs specializing in compact digital timers, leveraging mature PCB assembly infrastructure and access to Tier-1 component suppliers (e.g., microcontrollers, LCD modules, and quartz oscillators). Zhejiang’s Ningbo and Yiwu regions focus on cost-optimized mechanical and electromechanical timers, utilizing locally sourced ABS/PC housings and stamped metal contacts to achieve material cost advantages of 18–22% versus Southeast Asian or Eastern European producers.

These clusters operate under vertically integrated models: over 65% of verified suppliers maintain in-house SMT lines, injection molding facilities, and final assembly cells within single-site campuses. This integration enables standardized timer 24 min units to be produced at scale (average monthly output: 120,000–350,000 units), with lead times averaging 18–28 days for standard configurations. Buyers benefit from localized sourcing ecosystems where PCB fabricators, battery suppliers (CR2032, AA), and packaging vendors are co-located within 30km, reducing logistics coordination overhead and enabling rapid iteration for time-sensitive applications such as laboratory equipment, kitchen appliances, and industrial process controls.

How to Choose Timer 24 Min Suppliers?

Prioritize these verification protocols when selecting partners:

Technical Compliance

Require ISO 9001:2015 certification as minimum quality system validation. For export to EU markets, RoHS 3 (EU 2015/863) and REACH compliance are mandatory; for North America, UL recognition or ETL listing for power supply components is strongly advised. Verify timer accuracy specifications against IEC 60730-1 Annex H (±0.5% tolerance at 24-minute interval) and confirm battery life testing reports (≥12 months continuous operation at 25°C).

Production Capability Audits

Evaluate physical infrastructure and process control:

- Minimum 2,000m² facility area with climate-controlled SMT and aging test rooms

- Dedicated QA/QC personnel comprising ≥8% of total workforce

- In-house functional testing capability covering timing drift, button actuation cycles (>100,000 cycles), and low-voltage cutoff thresholds

Cross-reference automated test logs with on-time delivery rates (target ≥96%) to validate consistency across batch production.

Transaction Safeguards

Mandate third-party inspection (e.g., SGS or BV) prior to shipment for orders exceeding 5,000 units. Require AQL 2.5 sampling plans per ISO 2859-1 for visual, functional, and packaging checks. Analyze supplier transaction histories via verifiable export records (customs manifest data) rather than platform-based ratings alone. Pre-shipment sample testing must include temperature cycling (−10°C to +50°C, 5 cycles) and humidity exposure (95% RH, 48h) to assess real-world reliability.

What Are the Best Timer 24 Min Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Shenzhen Xingyue Electronics Co., Ltd. | Guangdong, CN | 12 | 180+ | 12,500+m² | 99.2% | ≤1h | 4.9/5.0 | 41% |

| Ningbo Huayi Timing Devices | Zhejiang, CN | 9 | 95+ | 8,200+m² | 98.7% | ≤2h | 4.8/5.0 | 38% |

| Dongguan Zhongke Precision Tech | Guangdong, CN | 7 | 140+ | 9,800+m² | 99.5% | ≤1h | 4.9/5.0 | 52% |

| Yiwu Jinhua Timer Manufacturing | Zhejiang, CN | 5 | 75+ | 5,600+m² | 97.8% | ≤2h | 4.7/5.0 | 24% |

| Shenzhen Lianhua Microelectronics | Guangdong, CN | 11 | 210+ | 15,300+m² | 98.4% | ≤1h | 4.9/5.0 | 47% |

Performance Analysis

High-volume suppliers like Shenzhen Lianhua Microelectronics and Dongguan Zhongke demonstrate superior process stability, evidenced by 98.4–99.5% on-time delivery and 47–52% reorder rates—indicative of consistent timing accuracy and build quality across production runs. Guangdong-based suppliers dominate responsiveness and technical documentation turnaround, with 80% providing full BOMs and test reports within 24 hours of inquiry. Zhejiang suppliers offer stronger value for mechanically actuated variants (e.g., rotary dials, spring-wound mechanisms), while Guangdong firms lead in programmable LCD variants with backlighting and multi-stage alarms. Prioritize partners with ≥98% on-time delivery, ISO 9001-certified QA systems, and documented aging test results for long-term reliability assurance.

FAQs

How to verify timer 24 min supplier reliability?

Cross-check ISO 9001 certificates against CNAS-accredited audit reports. Request traceability documentation for critical components (e.g., microcontroller datasheets, battery safety certifications). Analyze customer reviews focusing on post-shipment calibration drift and battery leakage incidents—not just aesthetic defects.

What is the average sampling timeline?

Standard digital timer samples require 10–16 days. Custom firmware (e.g., dual-mode countdown/timer, USB configuration) adds 7–12 days. Mechanical variants with custom housing molds extend sampling to 25–35 days. Air freight adds 5–8 days for global delivery.

Can suppliers ship timers worldwide?

Yes, established manufacturers handle FOB, CIF, and DAP terms with IATA-compliant lithium battery shipping documentation (UN3481 for CR2032-equipped units). Confirm compliance with destination-country labeling requirements: CE marking for EU, KC mark for South Korea, and PSE for Japan.

Do manufacturers provide free samples?

Free samples are rare for finished timers. Suppliers typically charge 120–180% of unit production cost for first samples, waiving fees only for confirmed POs exceeding 20,000 units. Sample orders include functional test reports and packaging mockups.

How to initiate customization requests?

Submit technical specifications including display type (LCD/LED), power source (battery-only vs. AC/DC adapter), enclosure material (ABS, PC, or food-grade PP), and required certifications (UL, CE, RoHS). Reputable suppliers deliver schematic revisions within 5 business days and functional prototypes within 18–22 days.