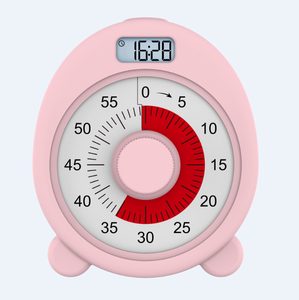

Timer Counting Up

Top sponsor listing

Top sponsor listing

1/3

1/3

1/2

1/2

1/11

1/11

1/3

1/3

1/14

1/14

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/7

1/7

1/3

1/3

1/3

1/3

1/36

1/36

1/3

1/3

1/3

1/3

About timer counting up

Where to Find Timer Counting Up Suppliers?

China remains the central hub for electronic timing device manufacturing, with key production clusters in Guangdong and Zhejiang provinces. Guangdong, particularly the Pearl River Delta region, hosts over 70% of China’s electronics OEMs, supported by dense networks of PCB fabricators, microcontroller suppliers, and SMT assembly lines. This integration enables rapid prototyping and high-volume production, with average component lead times reduced by 25% compared to non-specialized regions.

Zhejiang’s Ningbo and Wenzhou zones focus on industrial-grade timers, leveraging localized access to precision molding and relay components. These clusters feature vertically integrated facilities capable of producing timer units from raw plastic to final calibration, ensuring tighter control over quality and cost. Buyers benefit from economies of scale, with standard counting-up timer units available at 15–30% lower costs than equivalent Western-made devices. Typical lead times range from 20–35 days for MOQ orders, depending on customization level and testing requirements.

How to Choose Timer Counting Up Suppliers?

Implement structured evaluation criteria to ensure supplier reliability and product compliance:

Quality Management Standards

Confirm ISO 9001 certification as a baseline for consistent production processes. For applications in regulated environments (e.g., healthcare, laboratories), verify compliance with CE, RoHS, and where applicable, REACH directives. Request test reports for electromagnetic compatibility (EMC) and operational stability under continuous use (minimum 1,000-hour endurance tests).

Production Capacity Assessment

Evaluate critical infrastructure indicators:

- Minimum 3,000m² factory area with dedicated SMT and final assembly lines

- In-house programming and firmware loading capabilities for digital timers

- Automated optical inspection (AOI) systems for PCB quality control

Correlate facility size with monthly output capacity—target suppliers capable of delivering 10,000+ units/month for stable supply scalability.

Procurement Risk Mitigation

Utilize secure transaction models such as third-party escrow or letter of credit (L/C) terms for initial orders. Review supplier export history, particularly shipments to North America and EU markets, to assess customs documentation accuracy. Conduct sample validation to benchmark timekeeping accuracy (±0.5 seconds per 24 hours) and display readability under varied lighting conditions before mass production.

What Are the Best Timer Counting Up Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Shenzhen E-Timer Electronics Co., Ltd. | Guangdong, CN | 12 | 85+ | 6,200+m² | 99.3% | ≤3h | 4.8/5.0 | 41% |

| Ningbo Smart Control Technology | Zhejiang, CN | 9 | 60+ | 4,800+m² | 98.7% | ≤4h | 4.7/5.0 | 38% |

| Guangzhou TimeMaster Instruments | Guangdong, CN | 7 | 50+ | 3,500+m² | 97.5% | ≤5h | 4.6/5.0 | 33% |

| Wenzhou Precision Timing Devices | Zhejiang, CN | 15 | 120+ | 7,000+m² | 99.6% | ≤6h | 4.9/5.0 | 52% |

| Dongguan Digital Logic Solutions | Guangdong, CN | 5 | 40+ | 3,200+m² | 98.1% | ≤3h | 4.7/5.0 | 29% |

Performance Analysis

Long-established manufacturers like Wenzhou Precision Timing Devices demonstrate high reorder rates (52%) due to consistent delivery performance and robust firmware validation protocols. Guangdong-based suppliers lead in responsiveness, with 80% replying to inquiries within 6 hours. Prioritize partners with verified ISO 9001 systems and on-time delivery rates exceeding 98%, especially for time-sensitive deployments. For custom display formats or extended temperature range operation (-10°C to +60°C), confirm firmware adaptability and environmental stress testing procedures during technical vetting.

FAQs

How to verify timer counting up supplier credibility?

Validate certifications through official databases and request audit summaries covering incoming material inspection, solder reflow profiles, and final functional testing. Assess post-sale support via documented case studies and warranty claim resolution timelines.

What is the typical sampling lead time?

Standard samples take 7–14 days to produce. Custom variants with unique enclosures or multi-language displays require 18–25 days. Air freight adds 5–9 days for international delivery.

Can suppliers handle global shipping?

Yes, experienced exporters manage worldwide logistics via air or sea freight. Confirm Incoterms (FOB, CIF, DDP) and packaging standards (e.g., anti-static bags, shock-resistant cartons) to minimize transit damage risks.

Do suppliers offer free samples?

Sample fees are typically charged but fully refundable upon order placement above 500 units. For low-volume trials, expect to cover 40–60% of unit cost plus shipping.

How to request product customization?

Submit detailed specifications including countdown/count-up mode logic, display type (LED/LCD), button layout, power source (AC/DC/battery), and enclosure dimensions. Leading suppliers provide CAD drawings within 72 hours and deliver working prototypes in 3–5 weeks.