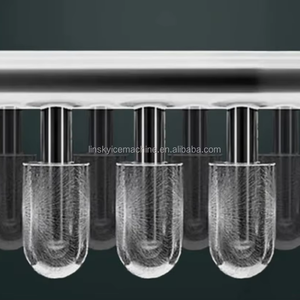

Tiny Ice Maker Machine

Top sponsor listing

Top sponsor listing

1/2

1/2

1/8

1/8

1/28

1/28

1/10

1/10

1/18

1/18

1/4

1/4

1/14

1/14

CN

CN

1/21

1/21

About tiny ice maker machine

Where to Find Tiny Ice Maker Machine Suppliers?

China remains the dominant hub for compact refrigeration equipment manufacturing, with key production clusters in Guangdong, Zhejiang, and Henan provinces. These regions host vertically integrated supply chains encompassing compressor fabrication, sheet metal processing, injection molding, and final assembly—enabling streamlined production of tiny ice maker machines. Guangdong’s Foshan and Shenzhen zones specialize in consumer-grade appliances, leveraging proximity to port infrastructure for rapid export fulfillment. Meanwhile, Zhejiang’s Ningbo and Hangzhou areas focus on mid-to-high-end models with smart controls and energy-efficient compressors, supported by localized R&D centers.

The industrial ecosystem supports cost efficiency through consolidated component sourcing—evaporators, condensers, refrigerant charging systems, and control boards are available within 50km radii of major factories. This integration reduces logistics overhead and enables faster prototyping cycles (typically 7–14 days). Buyers benefit from scalable output, with leading facilities reporting monthly capacities exceeding 10,000 units. Average production lead times range from 25–40 days for standard orders, while air freight options allow delivery within 5–8 days post-shipment.

How to Choose Tiny Ice Maker Machine Suppliers?

Procurement decisions should be guided by systematic evaluation of technical, operational, and transactional performance indicators:

Quality Management Systems

Prioritize suppliers with ISO 9001 certification or equivalent quality frameworks. For markets requiring regulatory compliance (EU, North America), confirm CE, RoHS, or ETL certification availability. Request test reports for critical parameters: refrigerant leakage (R600a/R134a), energy consumption per cycle, noise levels (≤45 dB), and ice yield consistency over 24-hour operation.

Production and Customization Capability

Assess supplier infrastructure based on the following benchmarks:

- Minimum factory area of 3,000m² indicating capacity for dedicated production lines

- In-house capabilities including sheet metal stamping, plastic injection molding, refrigerant filling, and electronic control board assembly

- Demonstrated customization scope: color variants (ABS/PP housing), logo printing, voltage adaptation (110V/220V), tank capacity adjustments (0.5L–2L), and compressor type (rotary vs. reciprocating)

- Design for manufacturability support—suppliers should provide CAD drawings and 3D renderings within 72 hours of inquiry

Transaction Reliability Metrics

Analyze verifiable performance data from trusted sourcing platforms:

- On-time delivery rate ≥97% indicates reliable logistics coordination

- Average response time ≤4 hours reflects operational responsiveness

- Reorder rate above 25% suggests customer satisfaction and product reliability

- Annual online transaction volume exceeding US $300,000 demonstrates market validation

Conduct sample testing before bulk ordering—evaluate ice formation speed (≤6 minutes per batch), cube clarity, automatic shut-off functionality, and thermal insulation efficiency after continuous 8-hour operation.

What Are the Best Tiny Ice Maker Machine Suppliers?

| Company Name | Location | Verified Supplier Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Key Product Features |

|---|---|---|---|---|---|---|---|---|

| Foshan Keku Electrical Appliance Co., Ltd. | Foshan, Guangdong | Custom Manufacturer | US $510,000+ | 58% | ≤10h | 29% | Color, size, logo, packaging, label, material, power, hopper, tank, graphic, compressor, model, body shape | Multi-tank designs, precool function, variable refrigerant capacity |

| Ningbo Yingyi International Trade Co., Ltd. | Ningbo, Zhejiang | Multispecialty Supplier | US $210,000+ | 100% | ≤2h | 27% | Color, size, logo, packaging, label, graphic | Smart countertop models, dual water inlet, portable design |

| Luohe Xingdian Electromechanical Equipment Co., Ltd. | Luohe, Henan | Multispecialty Supplier | US $640,000+ | 99% | ≤1h | <15% | Not specified | Commercial-grade mini units, 100kg/24h output, grid ice cubes |

| Shanghai Sihao Machinery Equipment Co., Ltd. | Shanghai | Unverified | US $2,100,000+ | 97% | ≤5h | 15% | Color, weight, packaging, label, output, material, size, condensation, logo, storage capacity, graphic, compressor, dimensions | Portable home/car units, instant ice making, pop-style desktop models |

| Guangdong No. 7 Warehouse Hotel Supplies Co., Ltd. | Guangdong | Multispecialty Supplier | US $350,000+ | 99% | ≤4h | 26% | Capacity | Electric countertop, solar-powered variants, freezer combos |

Performance Analysis

Shanghai Sihao leads in transaction volume (US $2.1M+ annual revenue), suggesting strong market penetration and distribution networks, though its reorder rate (15%) may indicate room for improvement in post-sale satisfaction. Ningbo Yingyi stands out for responsiveness (≤2h average reply) and perfect on-time delivery (100%), making it a reliable choice for time-sensitive procurement. Luohe Xingdian offers high-output commercial models but lacks detailed customization transparency. Foshan Keku provides extensive configurability across materials, aesthetics, and components—ideal for private-label branding—despite a lower on-time delivery rate (58%). Guangdong No. 7 Warehouse shows balanced performance with consistent fulfillment (99%) and moderate reorder activity (26%), supporting scalability for hospitality and retail sectors.

FAQs

How to verify tiny ice maker machine supplier reliability?

Cross-check certifications (CE, RoHS, ISO) via official registries. Request factory audit reports or video walkthroughs confirming production lines, QC stations, and inventory management. Evaluate supplier credibility using platform-verified metrics: on-time delivery history, dispute resolution records, and buyer feedback focusing on product durability and after-sales service.

What is the typical sampling timeline?

Standard samples are produced within 7–12 days. Customized units requiring mold modifications or new control boards may take 18–25 days. Air shipping adds 5–9 days depending on destination. Sample costs typically cover 40–60% of unit price, often deductible from future bulk orders.

Can suppliers ship globally?

Yes, experienced exporters manage international logistics under FOB, CIF, or DDP terms. Confirm Incoterms alignment with your import strategy. Most suppliers partner with major carriers (DHL, FedEx, COSCO) and can provide customs documentation, including packing lists, commercial invoices, and certificates of origin.

Do manufacturers offer free samples?

Free samples are rare for finished appliances due to component costs. However, suppliers may waive fees for trial orders exceeding 100 units. Some offer discounted sampling programs to qualified buyers with verified business credentials.

How to initiate customization requests?

Submit detailed specifications covering desired dimensions, ice output (kg/24h), power requirements, housing material (ABS vs. stainless steel), user interface (LED vs. digital), and branding elements (logo placement, color Pantone codes). Reputable suppliers will respond with engineering drawings, BOM breakdowns, and tooling cost estimates within 3–5 business days.