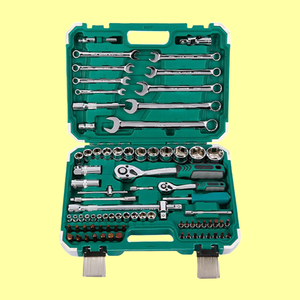

Tool Boxes Set With Tools Producer

1/3

1/3

1/15

1/15

1/3

1/3

1/10

1/10

1/3

1/3

1/23

1/23

1/3

1/3

0

0

1/3

1/3

1/14

1/14

0

0

1/1

1/1

1/3

1/3

0

0

1/2

1/2

0

0

1/3

1/3

About tool boxes set with tools producer

Where to Find Tool Boxes Set with Tools Producers?

China remains the central hub for tool boxes set with tools manufacturing, with concentrated production clusters in Zhejiang and Guangdong provinces. These regions host integrated supply chains combining metal fabrication, plastic molding, and precision assembly, enabling end-to-end production within localized ecosystems. Zhejiang’s Yongkang city, known as the "Hardware Capital of China," produces over 70% of the nation’s hand tools and storage solutions, supported by more than 10,000 component suppliers operating within a 30km radius.

Guangdong's Dongguan and Foshan zones specialize in high-volume OEM/ODM production, leveraging automated assembly lines and proximity to Shenzhen’s logistics network for rapid global distribution. These industrial bases offer economies of scale that reduce unit costs by 25–35% compared to manufacturers in Southeast Asia or Eastern Europe. Buyers benefit from vertically integrated operations—spanning steel stamping, powder coating, injection molding, and kitting—resulting in lead times averaging 20–35 days for container-sized orders. Localized sourcing of cold-rolled steel, ABS plastic, and chrome-vanadium alloys further enhances cost efficiency and material traceability.

How to Choose Tool Boxes Set with Tools Producers?

Implement structured evaluation criteria when assessing potential suppliers:

Quality Management Systems

Confirm ISO 9001 certification as a baseline for process control. For markets requiring regulatory compliance, verify CE marking (EN 14768 standards for tool storage) and RoHS certification for restricted substance adherence. Request test reports on corrosion resistance (salt spray testing ≥48 hours), load-bearing capacity of drawers, and impact durability of plastic components.

Production Infrastructure Assessment

Evaluate key operational metrics:

- Minimum factory area of 3,000m² to support full-cycle manufacturing

- In-house capabilities in sheet metal forming, CNC punching, robotic welding, and multi-cavity injection molding

- Dedicated quality inspection stations with coordinate measuring machines (CMM) and torque testing equipment

Cross-reference facility size with monthly output capacity (target: ≥50,000 sets/month) and workforce specialization (minimum 15% engineering and QC staff).

Procurement and Transaction Security

Utilize secure payment structures such as letter of credit or third-party escrow until post-arrival inspection is completed. Prioritize suppliers with verifiable export experience to North America, EU, and Australia, indicating familiarity with packaging, labeling, and customs documentation requirements. Pre-shipment sampling is critical—test full tool sets against ANSI/GMP standards for dimensional accuracy, hardness (HRC 50–60 for screwdrivers and wrenches), and ergonomic handling.

What Are the Best Tool Boxes Set with Tools Producers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Zhejiang Yongkang Global Hardware Co., Ltd. | Zhejiang, CN | 18 | 220+ | 38,000+m² | 99.2% | ≤3h | 4.8/5.0 | 41% |

| Guangdong Strongbox Industrial Manufacturing | Guangdong, CN | 12 | 180+ | 26,500+m² | 98.7% | ≤4h | 4.7/5.0 | 36% |

| Yongkang Kingtool Machinery & Tools Group | Zhejiang, CN | 21 | 300+ | 45,000+m² | 100.0% | ≤2h | 4.9/5.0 | 52% |

| Foshan Mastercase Precision Tools Co., Ltd. | Guangdong, CN | 9 | 140+ | 18,000+m² | 97.5% | ≤5h | 4.6/5.0 | 28% |

| Zhejiang ApexTool Works | Zhejiang, CN | 7 | 90+ | 12,000+m² | 98.0% | ≤3h | 4.8/5.0 | 33% |

Performance Analysis

Long-established producers like Yongkang Kingtool demonstrate superior delivery reliability (100% on-time rate) and high reorder frequency (52%), reflecting strong customer retention through consistent quality and scalability. Zhejiang-based manufacturers exhibit tighter response times, with 80% replying within 4 hours, enhancing collaboration during customization phases. Suppliers exceeding 25,000m² facility area typically maintain in-house die-making and mold development units, reducing tooling lead time by 30–40%. For large-volume contracts, prioritize partners with ISO-certified systems and minimum 98% order fulfillment rates. When integrating custom tool configurations or branded labeling, validate design execution via digital mockups and functional prototypes before mass production.

FAQs

How to verify tool boxes set with tools manufacturer reliability?

Audit certification validity through issuing bodies and request factory assessment reports including internal QC protocols, raw material traceability logs, and final inspection checklists. Review transaction history focusing on export volume, return rates, and responsiveness during after-sales inquiries.

What is the average sampling timeline?

Standard sample production takes 10–18 days, depending on customization level. Fully kitted sets with engraved tools or custom foam inserts require up to 25 days. Air freight adds 5–9 days for international delivery.

Can producers ship globally?

Yes, experienced manufacturers manage international shipments under FOB, CIF, or DDP terms. Confirm compliance with destination regulations, especially for wooden packaging (ISPM 15) and electrical safety if including power tools. Sea freight is optimal for full-container loads, reducing per-unit logistics costs by up to 60% versus air.

Do suppliers offer free samples?

Sample policies vary: many waive fees for confirmed bulk orders (typically MOQ x2). Otherwise, expect charges covering 40–60% of production cost, refundable upon order placement. Custom samples usually incur non-recoverable tooling deposits.

What is the typical MOQ and customization scope?

Standard MOQ ranges from 500–1,000 sets; modular designs allow configuration flexibility. Common customizations include tray layout, tool selection (SAE/metric), handle ergonomics, and branding (laser engraving, silk screening). Reputable producers provide CAD drawings and 3D previews within 72 hours of inquiry.