Tool Cases Producer

Top sponsor listing

Top sponsor listing

About tool cases producer

Where to Find Tool Cases Producers?

China remains the global epicenter for tool case manufacturing, with concentrated production clusters in Zhejiang and Guangdong provinces driving competitive advantage. Hangzhou and Ningbo in Zhejiang host vertically integrated facilities specializing in aluminum and composite material fabrication, supported by mature metalworking supply chains that reduce component lead times by 20–30%. Shenzhen in Guangdong focuses on injection-molded plastic cases, leveraging local expertise in precision molding and rapid prototyping to serve high-volume OEMs.

These industrial hubs offer streamlined access to full-cycle production—from raw material sourcing to final assembly—within tightly networked ecosystems. Suppliers benefit from co-located CNC machining, foam inlay cutting, and surface treatment services, enabling faster turnaround for both standard and custom configurations. Buyers can expect typical lead times of 15–30 days for bulk orders, with cost efficiencies derived from localized logistics and economies of scale. The region’s specialization supports flexible order volumes, from small batches with customization to large-scale exports.

How to Choose Tool Cases Producers?

Effective supplier selection requires rigorous evaluation across three core dimensions:

Production & Customization Capability

Prioritize manufacturers with in-house production lines capable of handling multiple materials—aluminum, ABS, PP, and EVA sponge inserts. Confirm capacity for key processes: CNC cutting, vacuum forming, UV printing, laser etching, and custom foam die-cutting. Suppliers should support dimensional adjustments, color matching, logo integration (via silk screen, sticker, or mold imprint), and interior layout design. Verified product listings exceeding 80 SKUs indicate robust catalog diversity and engineering flexibility.

Quality & Operational Performance

Assess operational reliability using verifiable metrics:

- On-time delivery rate ≥95%

- Average response time ≤3 hours

- Reorder rate below 25% (indicating stable customer satisfaction)

- Minimum online transaction volume of US $100,000+ as evidence of consistent export activity

Cross-reference these indicators with documented quality control procedures. While formal ISO 9001 certification is not always listed, consistent performance metrics suggest established internal QC systems. For sensitive applications (medical, electronics, defense), verify material compliance with RoHS or flame-retardant standards.

Transaction Security & Support

Favor suppliers offering transparent pricing structures, low minimum order quantities (MOQs as low as 1–10 pieces), and sample availability. Evaluate communication responsiveness and technical clarity during inquiry phases. Use secure payment methods with milestone-based release terms where possible. Pre-shipment inspection rights and clear return policies mitigate fulfillment risks, especially for customized units.

What Are the Best Tool Cases Producers?

| Company Name | Main Products (Listings) | Customization Options | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate |

|---|---|---|---|---|---|---|

| Hangzhou Gude Tools Co., Ltd. | Tool Cases (872), Tool Boxes (200) | Color, shape, foam, lid, sticker, UV sticker, mold, packaging, label, EVA sponge, size, drawings, paper sticker, accommodation, logo, waterproof PVC, graphic, dimensions, height | US $40,000+ | 100% | ≤7h | <15% |

| Ningbo Bluespeed Tech Co., Ltd. | Tool Cases (82), Electronics Enclosures (16) | Not specified | US $1,000+ | 100% | ≤2h | <15% |

| Shenzhen Hengtime Plastic Co, Ltd. | Tool Cases (137), Tool Boxes (33) | Not specified | US $10,000+ | 80% | ≤10h | <15% |

| Ningbo Uworthy Electronic Technology Co., Ltd. | Tool Cases (Not specified) | Color, material, size, foam design, logo, packaging style, label, graphic, catalogue | US $330,000+ | 95% | ≤2h | 15% |

| Ningbo Sunyoung Enclosure Co., Ltd. | Tool Cases (Not specified), Aluminum Enclosures | Tray, wheels, color, foam, fireproof, hard plastic, tie rods, rectangular cuts, lock, logo, waterproof, graphic, UV printing, silk print, drawers, inlay, sticker, mold, packaging, label, strap, laser etching, hole, explosion-proof, material, size, style, sleeves, dimensions, frame | US $1,800,000+ | 100% | ≤3h | 22% |

Performance Analysis

Hangzhou Gude Tools demonstrates extensive product breadth with over 870 tool case listings, indicating strong market presence and diversified design capability. Despite a longer response time (≤7h), its 100% on-time delivery and low reorder rate suggest reliable execution for standard products. Ningbo Bluespeed stands out for exceptional responsiveness (≤2h) and perfect delivery record, though its smaller listing base may limit configurability for niche requirements.

Ningbo Sunyoung leads in customization depth, supporting over 25 modification parameters including structural features like drawers, explosion-proof materials, and laser etching—ideal for specialized industrial or military-grade applications. With the highest reported revenue (US $1.8M+) and flawless delivery performance, it is well-suited for medium-to-large volume buyers requiring advanced personalization. Ningbo Uworthy balances scalability and service, combining high transaction volume (US $330K+) with fast response and 95% punctuality, making it a viable option for export-oriented buyers seeking responsive partners.

Shenzhen Hengtime, while offering competitive pricing and plastic-focused expertise, shows lower delivery reliability (80%) and slower response (≤10h), which may pose risks for time-sensitive procurement. Its strength lies in injection-molded solutions but should be evaluated carefully for critical supply chains.

FAQs

What materials are commonly used by tool cases producers?

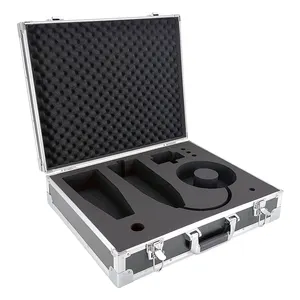

Primary materials include aircraft-grade aluminum for impact-resistant flight cases, high-density polyethylene (HDPE), ABS, and PP for lightweight plastic variants. Interior linings typically use die-cut EVA foam or velvet for equipment stabilization and protection.

What is the typical MOQ for custom tool cases?

MOQs vary by manufacturer and complexity. Basic models start at 1–10 pieces; fully customized designs (with molds, logos, unique foam layouts) often require 50–100 units to amortize setup costs. Some suppliers offer prototype samples at reduced MOQs.

How long does production take for custom tool cases?

Standard orders take 15–20 days after confirmation. Custom tooling or complex foam inserts add 5–10 days. Add 7–14 days for international shipping via air or sea freight depending on destination.

Can suppliers provide design assistance for custom cases?

Yes, leading producers offer engineering support including 2D/3D drawings, foam layout planning, and material recommendations. Suppliers like Ningbo Sunyoung and Hangzhou Gude list comprehensive customization parameters, suggesting in-house design teams capable of translating functional requirements into manufacturable solutions.

Are samples available before placing bulk orders?

Most suppliers provide samples, often at a premium price covering production and shipping. Sample fees may be credited toward future orders. Expect 7–15 days for sample production, depending on customization level.