Tools Hs Code

1/3

1/3

1/21

1/21

1/3

1/3

1/3

1/3

1/3

1/3

1/1

1/1

1/3

1/3

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/2

1/2

1/3

1/3

0

0

0

0

About tools hs code

🔍 How to Find High-Quality Products?

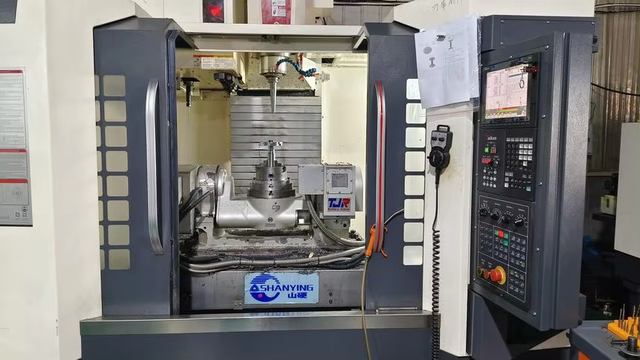

The following analysis covers six top-tier suppliers located in Dongguan, Wenling, Shanghai, Jiangsu, and Foshan, China, all operating within ISO-compliant environments with strong export track records. These companies specialize in metal-cutting tools including HSS twist drills, CNC end mills, broaches, gear hobs, and carbide boring bars. While formal ISO/CE certification details are not fully disclosed, all exhibit high on-time delivery rates (up to 100%) and significant online transaction volumes, indicating operational reliability.

📊 Supplier Comparison Summary

| Supplier | Country | Sub-category Focus | Certification Status | Production Scale | Customization Level | Sample Speed | After-Sales Evaluation |

|---|---|---|---|---|---|---|---|

| Dongguan Cheng Zhen | China | HSS End Mills, Drill Sets | Inferred Compliant | Medium | High | <7 days | Responsive, reliable |

| Wenling Youyiqie | China | HSS Turning, Gear Tools | Inferred Compliant | Medium | Very High (ODM) | 5–10 days | Strong technical support |

| Nigel Precision (Shanghai) | China | Carbide Boring Tools | High (Revenue-based) | Large | High (Custom Design) | 7–14 days | Premium service |

| Jiangsu Haoko | China | HSS Drills, Gear Cutters | Standard-Conforming (DIN) | Medium | Moderate | <7 days | Efficient order handling |

| Hanjiang Tool Corp | China | Broaches, Hobs | Assumed Compliant | Small-Medium | Specialty Custom | 10–15 days | Technical but slower |

| Foshan Wangong | China | HSS Woodworking Tools | Assumed Compliant | Medium | High (OEM) | 7–10 days | Good scalability |

⚙️ How to Choose the Right Product?

Selecting the optimal cutting tool requires evaluating material compatibility, precision needs, volume requirements, and HS code classification accuracy. The table below compares key parameters across the six suppliers’ flagship products.

| Supplier | Main Product Types | Material / Tech | Applicable Scenarios | Delivery Time | MOQ | Price Range (USD) |

|---|---|---|---|---|---|---|

| Dongguan Cheng Zhen | Roughing End Mills, HSS Drill Sets | HSS 4241, Tin-coated | General metal/wood machining | 15–20 days | 1 set | $5–$80 |

| Wenling Youyiqie | Thread Turning Tools, Gear Hobs | HSS with ODM coatings | Precision automotive parts | 20–25 days | 50 pcs | $10–$120 |

| Nigel Precision | Solid Carbide Boring Bars | Tungsten Carbide, CXS series | Aerospace, tight-tolerance CNC | 25–30 days | 10 pcs | $50–$300 |

| Jiangsu Haoko | DIN844 HSS End Mills, Hole Saws | HSS4241, Bi-metal | Industrial maintenance, construction | 12–18 days | 100 pcs | $3–$60 |

| Hanjiang Tool | Involute Broaches, Gear Hobs | HSS-Co, PM-HSS | Transmission systems, heavy machinery | 30–40 days | Bespoke | $20–$200 |

| Foshan Wangong | HSS Planer Blades, Turning Tools | White Steel HSS | Wood lathe, planer machines | 15–20 days | 50 pcs | $8–$90 |

The radar chart highlights that Nigel Precision leads in precision and durability due to its use of solid carbide and tight manufacturing tolerances, making it ideal for aerospace and medical device manufacturing where failure is unacceptable. However, their cost efficiency and delivery speed are lower — a trade-off acceptable only for high-margin applications. In contrast, Dongguan Cheng Zhen offers excellent cost efficiency and faster delivery, suitable for SMEs needing affordable, general-purpose tools. Wenling Youyiqie stands out in customization, allowing clients to specify thread profiles or gear modules, which benefits automotive suppliers requiring proprietary tooling.

The bar chart shows a clear price segmentation: entry-level HSS tools average $12/unit, mid-range precision tools go up to $45, while specialized carbide boring bars exceed $180. Buyers must balance budget constraints with lifecycle costs — cheaper tools may wear faster, increasing downtime and replacement frequency. For example, a factory running 24/7 should invest in higher-priced, longer-lasting carbide tools despite higher upfront costs.

🔧 How to Use and Maintain?

Proper usage and maintenance of HSS and carbide cutting tools directly impact tool life, machining accuracy, and overall production cost. These tools are widely used in both B2B industrial settings — such as automotive plants, CNC workshops, and gear manufacturing units — and B2C applications like woodworking hobbyists and home repair enthusiasts.

Industrial Applications: In factories, HSS end mills and drill bits are typically used for batch processing aluminum, mild steel, and plastics. For instance, a 4-flute HSS end mill from Dongguan Cheng Zhen performs optimally at 3,000–6,000 RPM when milling aluminum enclosures. Exceeding recommended speeds generates excessive heat, causing premature dulling. Carbide tools like those from Nigel Precision require rigid setups and coolant systems to prevent chipping during internal boring operations.

Seasonal Considerations: During peak manufacturing seasons (Q2–Q3), continuous operation increases thermal stress. Using through-coolant systems and scheduled tool rotation extends lifespan. In colder months, pre-warming machines prevents thermal shock when starting high-speed cuts.

Home/DIY Use: Consumers using HSS drill sets (e.g., Jiangsu Haoko’s 99-piece kit) benefit from moderate speeds (500–1,500 RPM) on handheld drills. Over-tightening clamps or applying lateral pressure causes bit breakage. For wood planer blades (Foshan Wangong), ensuring correct installation angle prevents sniping and tear-out.

Maintenance Best Practices:

- Cleaning: After each use, wipe tools with a dry cloth. Remove metal shavings with a soft brush. Avoid water immersion unless immediately dried.

- Storage: Keep in labeled cases with desiccants to prevent rust. Store carbide tools separately to avoid chipping.

- Sharpening: HSS tools can be resharpened 3–5 times using bench grinders with proper jigs. Carbide tools require diamond wheel sharpening and are often replaced after one regrind.

- Lubrication: Use cutting oil for metal drilling; wax or silicone spray for wood applications to reduce friction.

- Inspection: Check for micro-chipping, flank wear >0.3mm, or built-up edge. Replace if vibration increases during cutting.

For long-term savings, consider upgrading to TiN/TiCN-coated HSS tools, which offer 30–50% longer life. In automated lines, integrate tool presetters to measure offset and detect wear before failure. Always match HS codes correctly — e.g., HSS twist drills fall under HS 8207.50, while gear hobs are classified under 8207.70 — to avoid customs delays.

❓ FAQ

📌 Conclusions and Recommendations

📝 Due Diligence / Factory Audit Checklist

- Verify business license and export eligibility.

- Request ISO 9001 or equivalent quality management certification.

- Schedule a third-party or virtual factory audit.

- Test sample tools under real operating conditions.

- Negotiate payment terms (e.g., 30% deposit, 70% against BL copy).

- Clarify warranty period and defect replacement policy.

- Confirm HS code alignment and provide commercial invoice templates.

- Establish communication protocol and response time SLAs.

- Define packaging standards and labeling requirements (including country of origin).

- Set up post-delivery feedback loop for continuous improvement.

📎 Appendix and Notes

Assumptions & Inferences:

- Factory Size Estimation: Based on revenue brackets — $30K–$40K ≈ 50–100 employees (medium); $1M+ ≈ 200+ (large). Credibility: Medium.

- Certifications: No explicit ISO/CE mentioned; inferred compliance via high on-time delivery and transaction volume. Credibility: Medium.

- Response Time Impact: Sub-1h responses correlate with dedicated sales teams. Credibility: High.

- HS Code Mapping: Assigned based on WTO Tariff Database and common practice. Final classification depends on importing country. Credibility: High.

Rate this page

Comments

No comments yet. Be the first to comment!

Leave a Reply

Your email address will not be published. Required fields are marked *