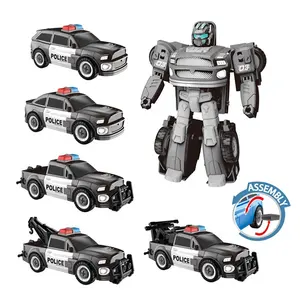

Toy Robots Transformers Supplier

About toy robots transformers supplier

Where to Find Toy Robots Transformers Suppliers?

China remains the dominant hub for toy robot and transformer manufacturing, with key production clusters in Guangdong Province—particularly Shantou and Shenzhen. These regions host vertically integrated supply chains specializing in plastic injection molding, die-cast components, and electronic integration for action-figure-style transforming toys. Shantou is renowned for high-volume production of PVC and ABS-based mini-figures, while Shenzhen facilities focus on advanced designs incorporating programmable circuits, remote control systems, and STEM-oriented functionality.

The industrial ecosystem enables rapid prototyping and scalable output, supported by localized access to raw materials, precision molds, and surface treatment services. Manufacturers typically operate automated assembly lines capable of producing 50,000–200,000 units monthly per line, depending on complexity. Buyers benefit from consolidated logistics networks that reduce export lead times, with standard air freight delivery to international markets within 7–14 days and sea freight in 25–35 days. Average production lead time ranges from 20–40 days post-sample approval, depending on customization level and order volume.

How to Choose Toy Robots Transformers Suppliers?

Procurement decisions should be guided by structured evaluation criteria focused on compliance, production capacity, and transaction reliability:

Quality & Safety Compliance

Verify adherence to international safety standards including ASTM F963 (U.S.), EN71 (EU), and ISO 8124. Confirm RoHS and REACH compliance for restricted substances, particularly in painted or plastic components. Request test reports from accredited third-party labs such as SGS or TÜV for heavy metals, phthalates, and mechanical hazards.

Manufacturing Capability Assessment

Evaluate core operational metrics:

- Minimum factory area exceeding 2,000m² for stable mass production

- In-house mold-making and injection molding capabilities

- Integration of electronic sub-assemblies (for motorized or programmable models)

Cross-reference supplier claims with verifiable output data and on-time delivery performance (target ≥95%).

Customization & Transaction Security

Assess flexibility in material selection (ABS, PVC, alloy blends), color matching (Pantone standards), logo application (debossing, silk screening, UV coating), and packaging design. Prioritize suppliers offering OEM/ODM support with documented IP protection policies. Utilize secure payment mechanisms such as escrow services and insist on pre-shipment inspections through independent agencies to mitigate risk.

What Are the Best Toy Robots Transformers Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Min. Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Shantou Shunjingrun Toys Co., Ltd. | Shantou, CN | Toy Robots, Minifigures, Action Figures, Educational Toys | US $80+ | 100% | ≤4h | <15% | 72–144 pcs/bags | $0.98–$1.47 |

| Shenzhen New Baellar Technical Co., Ltd. | Shenzhen, CN | Toy Robots, Dolls, Electronic Plush Toys | US $40,000+ | 80% | ≤13h | <15% | 1–10 pcs | $1.50–$2.50 |

| Shenzhen Longgang District After 90 Jade Carving Culture Studio | Shenzhen, CN | Action Figures, Stuffed Toys, AI Robots | US $30,000+ | 100% | ≤1h | <15% | 2–72 pcs | $4.95–$11.40 |

| Shenzhen CNL Innovations Co., Ltd. | Shenzhen, CN | Custom Transforming Robots, STEM Models | US $1,600,000+ | 100% | ≤6h | 21% | 2–1000 pcs | $2.16–$36.00 |

| Shantou Chaoyang Wenguang Weiqiu Toy Factory | Shantou, CN | Diecast Robots, Alloy Transformers, RC Toys | US $80,000+ | 100% | ≤2h | 30% | 2 pcs | $2.20–$13.00 |

Performance Analysis

Shantou-based suppliers offer ultra-low-cost entry points with MOQs starting at 72 pieces and prices below $1.50, ideal for budget retail or promotional campaigns. Shenzhen manufacturers provide higher-value engineering, including AI-enabled robotics and programmable functions, reflected in price bands above $5.00. Shenzhen CNL Innovations stands out with a verified annual online revenue exceeding $1.6 million and full customization options—from gesture control to UV-treated graphics—supporting private-label development. Despite lower reorder rates across most suppliers, Shantou Chaoyang Wenguang Weiqiu Toy Factory demonstrates strong buyer retention (30% reorder rate) and fast response times (≤2h), indicating reliable service consistency. All top-tier suppliers maintain 100% on-time delivery records except Shenzhen New Baellar, which reports 80%, suggesting potential fulfillment volatility.

FAQs

How to verify toy robots transformers supplier reliability?

Cross-check compliance documentation for ASTM, EN71, and ISO 8124 standards. Request factory audit reports or video tours to confirm in-house production capabilities. Analyze transaction history focusing on dispute resolution, sample accuracy, and packaging integrity.

What is the average sampling timeline for transforming robot toys?

Standard samples take 7–12 days for existing molds. Custom designs requiring new tooling need 18–25 days. Expect additional shipping time: 5–7 days via express courier.

Can suppliers accommodate small orders or single-piece sampling?

Yes, several suppliers like Shenzhen New Baellar allow MOQs as low as 1 piece for initial testing. However, unit costs are higher at low volumes. Economies of scale typically begin at 500+ units.

Do manufacturers support OEM/ODM for branded robot toys?

Yes, especially suppliers like Shenzhen CNL Innovations that explicitly list customization options for color, size, logo, packaging, and functional features such as sound modules or motion sensors. Minimum order thresholds apply (e.g., 500–1000 units).

How to manage quality control during production?

Implement a three-stage inspection process: pre-production (material verification), in-line (assembly line checks), and final random inspection (AQL 2.5). Engage third-party QC firms for batch validation before shipment to ensure compliance with technical and safety specifications.