Transformer Winding Machine Price

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

About transformer winding machine price

Where to Find Transformer Winding Machine Suppliers?

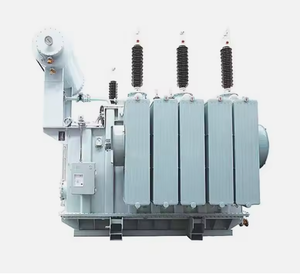

China remains the central hub for transformer winding machine manufacturing, with key production clusters in Fujian, Henan, Guangdong, and Zhejiang provinces. These regions host vertically integrated industrial ecosystems that support precision engineering, automation integration, and cost-efficient component sourcing. Xiamen and Dongguan have emerged as centers for CNC-controlled coil winding systems, leveraging proximity to electronics and power equipment supply chains. Henan’s electric machinery cluster benefits from established transformer component suppliers, enabling rapid prototyping and scalable production.

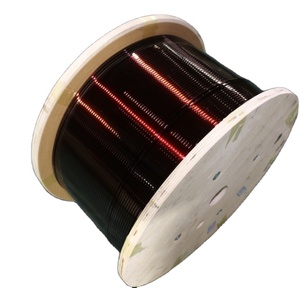

The concentration of technical expertise and supporting infrastructure allows manufacturers to offer competitive pricing and flexible configurations. Suppliers in these zones typically operate end-to-end production lines—from mechanical fabrication and electrical assembly to software calibration—reducing dependency on external vendors. This integration translates into lead times averaging 20–40 days for standard units and up to 60 days for fully customized systems. Buyers benefit from localized access to raw materials such as copper wire, insulation films, and motor components, which helps maintain stable pricing despite global commodity fluctuations.

How to Choose Transformer Winding Machine Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Capabilities and Equipment Specialization

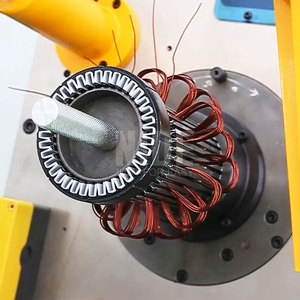

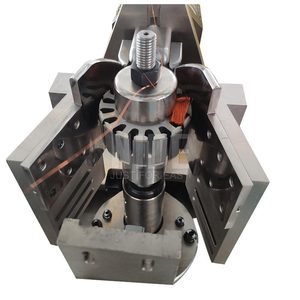

Assess whether the supplier specializes in specific winding technologies—such as toroidal, axial, or helical coil formation—and verify compatibility with your target applications (e.g., distribution transformers, UPS systems, or industrial inverters). Prioritize companies offering CNC-controlled machines with programmable logic controllers (PLCs), digital tension control, and multi-axis synchronization for high repeatability. Machines priced above $20,000 often include automated loading, real-time monitoring, and error detection systems.

Quality Assurance and Compliance

Confirm adherence to international quality standards. While formal ISO 9001 certification is not explicitly stated in available data, consistent on-time delivery rates (≥97%) and low reorder rates (<15%) indicate robust internal processes. For export compliance, ensure machines meet CE or IEC 61558 safety standards where applicable, particularly for use in European or North American markets. Request documentation on motor efficiency, insulation class ratings, and dielectric strength testing.

Production Capacity and Responsiveness

Evaluate supplier scalability through operational metrics:

- On-time delivery performance: Target suppliers with ≥98% fulfillment consistency

- Response time: Sub-6-hour response indicates strong customer service infrastructure

- Customization capability: Look for evidence of configurable options in material handling, spool size, wire gauge range, and HMI interfaces

- Online transaction volume: Suppliers reporting annual revenues over US $50,000 demonstrate market validation and order processing maturity

Procurement Safeguards

Utilize secure payment methods with inspection-based release terms. Conduct pre-shipment verification via video audits or third-party inspection services to validate machine functionality and build quality. Sample testing should assess winding accuracy, cycle time consistency, and fault recovery mechanisms before full-scale orders.

What Are the Best Transformer Winding Machine Suppliers?

| Company Name | Main Products | Price Range (USD) | Min. Order Quantity | On-Time Delivery | Avg. Response Time | Reorder Rate | Revenue Tier | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Xiamen Tob New Energy Technology Co., Ltd. | Coating Machines, Battery Equipment, Sealing Machines | Not publicly listed | Not specified | 100% | ≤3h | <15% | $50,000+ | Color, material, size, logo, packaging, graphics |

| Henan Yubian Electrician Co., Ltd. | Transformers, Electrical Wires | $2,880–26,800 | 1 piece | 100% | ≤4h | Not available | Data not available | Limited information |

| Dongguan Jinju Automation Equipment Co., Ltd. | Coil Winding Machines, Shafts | $10,000–21,142.86 | 1 piece | 100% | ≤6h | Not available | Data not available | High-efficiency, automatic CNC models |

| Wenzhou Wenyu Electric Co., Ltd. | Transformers, Voltage Regulators, Inverters | $8–336 | 1 piece | 80% | ≤3h | <15% | $9,000+ | Basic models at economy pricing |

| Guangzhou Minder-Hightech Co., Ltd. | Coil Winding Machines, Electronics Production Machinery | $3,000–$38,000 | 1 set | 100% | ≤21h | <15% | $130,000+ | Automatic, CNC, toroidal-specific systems |

Performance Analysis

Dongguan Jinju and Henan Yubian stand out for specialized winding equipment within the mid-to-high price segment ($10,000+), offering advanced automation features suitable for industrial-grade transformer production. Both report perfect on-time delivery records, indicating reliable logistics execution. Guangzhou Minder-Hightech presents the broadest product range and highest reported revenue tier, suggesting extensive export experience and capacity for large-volume contracts. Xiamen Tob offers customization flexibility across design elements, making it suitable for buyers requiring branded or integrated solutions. Wenzhou Wenyu provides entry-level machines at significantly lower price points but has a notably lower on-time delivery rate (80%), signaling potential fulfillment risks. Response times vary widely—from ≤3h among top-tier suppliers to over 20h—highlighting the importance of aligning procurement timelines with supplier responsiveness.

FAQs

What determines transformer winding machine price variation?

Price differences reflect automation level, control system sophistication, maximum wire diameter capacity, winding speed (rpm), and software capabilities. Manual semi-automatic models range from $50–$500, while CNC-driven systems with closed-loop feedback and multi-spindle operation exceed $20,000. Custom tooling, dual-station setups, and IoT connectivity further increase costs.

What is the typical MOQ and lead time?

Most suppliers list a minimum order quantity of 1 unit or set. Standard lead times range from 15 to 30 days post-deposit, depending on complexity. Customized machines may require 45–60 days for production and factory acceptance testing.

Can suppliers provide technical training and after-sales support?

Yes, many suppliers offer remote setup assistance, operation manuals in English, and troubleshooting guides. Some provide on-site technician deployment at additional cost. Verify warranty terms (typically 12 months) and availability of spare parts before purchase.

Are there options for energy-efficient or smart winding machines?

Advanced models incorporate variable frequency drives (VFDs), regenerative braking, and Ethernet/IP communication for Industry 4.0 integration. These features improve energy efficiency by 15–25% and allow centralized monitoring of winding parameters across production lines.

How to assess machine durability and precision?

Request test reports showing turn-to-turn tolerance (±0.1 mm typical), tension control stability, and alignment accuracy. Examine frame construction (steel vs. aluminum), bearing quality, and encoder resolution. High-end models use servo motors with sub-micron positioning accuracy for critical applications.