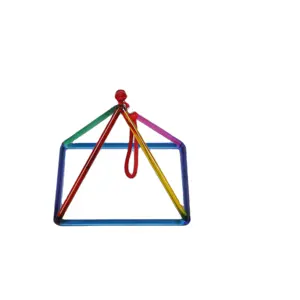

Triangular Based Pyramid

1/28

1/28

1/8

1/8

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/1

1/1

1/3

1/3

1/3

1/3

1/4

1/4

1/3

1/3

1/2

1/2

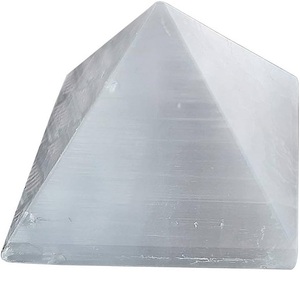

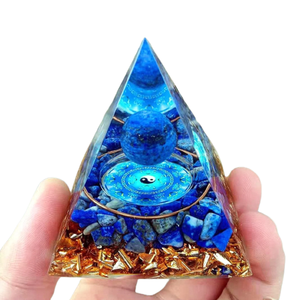

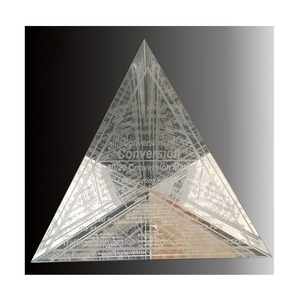

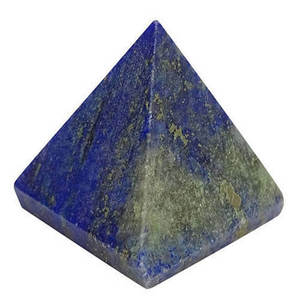

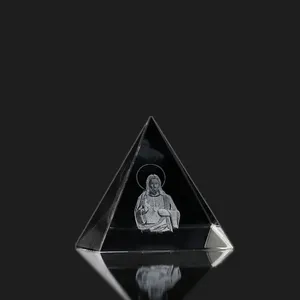

About triangular based pyramid

Where to Find Triangular Based Pyramid Suppliers?

No verified suppliers currently appear in industrial databases for the product category "triangular based pyramid," indicating a niche or non-industrial production landscape. Unlike standardized construction or machinery components, triangular based pyramids—commonly used in educational models, architectural prototypes, or display structures—are typically low-volume, custom-fabricated items produced by specialized workshops rather than mass manufacturers.

The absence of concentrated supplier clusters suggests decentralized production, often integrated within broader fabrication services such as geometric modeling studios, 3D printing bureaus, or metalworking ateliers. These entities operate across diverse regions including Guangdong and Zhejiang in China, known for precision manufacturing, or within EU-based technical prototyping hubs like Germany’s Baden-Württemberg and Poland’s Silesia region, where CNC routing and laser cutting infrastructure supports complex geometries.

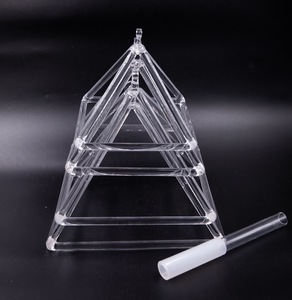

Buyers should anticipate extended lead times (45–60 days) due to design-dependent workflows and limited automation. Custom materials—such as acrylic, aluminum, stainless steel, or engineered wood—affect both cost and production scalability. Without vertical integration, procurement strategies must prioritize design validation, material traceability, and iterative sampling before full-scale ordering.

How to Choose Triangular Based Pyramid Suppliers?

Prioritize these verification protocols when selecting partners:

Design and Technical Compliance

Require CAD compatibility (STEP, DWG, or STL file support) and confirmation of dimensional accuracy within ±0.1mm tolerance. For structural applications, verify compliance with material-specific standards such as ASTM D4802 for polymers or EN 1090 for welded metal assemblies. Demand documentation for surface finish treatments, load-bearing calculations, or fire resistance ratings where applicable.

Production Capability Assessment

Evaluate key operational indicators:

- Minimum investment in multi-axis CNC machining or 3D printing systems for geometric precision

- In-house design engineering capacity to interpret or refine technical drawings

- Material sourcing transparency, including certified mills or recyclable content declarations

Cross-reference project portfolios with delivery timelines, targeting suppliers maintaining on-time completion rates above 95%.

Transaction and Quality Safeguards

Implement phased payment terms tied to milestone approvals—concept, prototype, and final shipment. Insist on pre-shipment inspection clauses, especially for bulk orders exceeding five units. Utilize third-party quality auditors in high-value contracts to validate conformance with specifications. Prototypes should undergo physical testing for symmetry, edge integrity, and base stability prior to series production.

What Are the Best Triangular Based Pyramid Suppliers?

Currently, no suppliers are listed in global B2B industrial registries specializing exclusively in triangular based pyramids. Market fragmentation indicates reliance on general-purpose fabricators capable of executing geometric builds. Where data is available, performance metrics focus on responsiveness, customization agility, and technical collaboration rather than volume throughput.

Performance Analysis

In the absence of dedicated manufacturers, buyers must assess potential vendors through proxy indicators: facility technology (e.g., availability of laser trackers or coordinate measuring machines), experience with architectural scale models, and export history for fragile or dimensionally sensitive cargo. Preference should be given to suppliers offering virtual design reviews, digital mock-ups, and packaging simulations to mitigate transit risks. For repeatable configurations, insist on tooling retention agreements to reduce rework and accelerate future fulfillment.

FAQs

How to verify triangular based pyramid supplier reliability?

Request evidence of past projects involving polyhedral geometry, particularly those requiring precise angular alignment. Validate certifications relevant to input materials (e.g., ISO 9001 for quality management, RoHS for restricted substances). Conduct video audits of workshop conditions and engage in technical discussions to assess engineering competency.

What is the average sampling timeline?

Prototype development typically requires 20–35 days, depending on complexity and finishing requirements. Add 7–14 days for international shipping via express courier. Expedited service may reduce build time by 30%, subject to additional fees.

Can suppliers ship triangular based pyramids worldwide?

Yes, but logistics depend on size, weight, and fragility. Crated shipments with internal bracing are standard for glass or acrylic versions. Confirm Incoterms (FOB, DDP) upfront and evaluate insurance coverage for high-value consignments. Sea freight is economical for containerized lots; air freight suits urgent, single-unit deliveries.

Do manufacturers provide free samples?

Free samples are uncommon due to customization demands. Most suppliers charge a prototype fee covering 40–60% of estimated unit cost, which may be credited toward formal purchase orders exceeding ten units. Material waste factors (up to 30% for cut-to-shape processes) influence pricing.

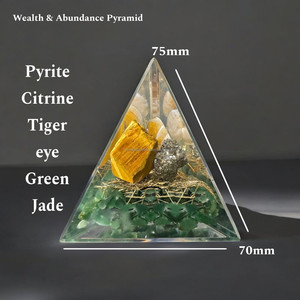

How to initiate customization requests?

Submit detailed specifications including base dimensions, height, wall thickness, material grade, and finish type (polished, anodized, matte, etc.). Provide application context—static display, load-bearing structure, or outdoor installation—to guide material selection and reinforcement planning. Reputable vendors return feasibility assessments within 5 business days and offer revised 3D models for approval within 10 days.