Turing Machine

1/18

1/18

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/23

1/23

0

0

1/3

1/3

CN

CN

1/17

1/17

1/3

1/3

1/14

1/14

1/3

1/3

CN

CN

1/14

1/14

0

0

1/3

1/3

1/1

1/1

CN

CN

1/18

1/18

About turing machine

Where to Find Turing Machine Suppliers?

The global supply base for machinery associated with the term "Turing machine" is primarily concentrated in China’s advanced manufacturing hubs, particularly in Guangdong, Zhejiang, and Liaoning provinces. While the theoretical Turing machine remains a conceptual model in computer science, industrial suppliers using this nomenclature typically offer precision automation equipment, CNC machining centers, wire processing systems, and component finishing machines—often branded under "Turing" as a proprietary name. Dongguan and Shenzhen in Guangdong province host specialized automation technology firms producing cable stripping and foam machinery, while Ningbo in Zhejiang focuses on motor rotor and armature processing systems. Dalian in Liaoning serves high-end lathe and turning center production, integrating milling and multi-axis CNC capabilities.

These regional clusters benefit from vertically integrated ecosystems, where raw material sourcing, precision machining, and final assembly occur within compact geographic zones. This integration enables lead times averaging 30–45 days for standard configurations, with cost advantages of 20–35% over equivalent Western-built industrial systems. Suppliers leverage local access to hardened steel, aluminum die-casting facilities, and electronic control components, reducing dependency on external procurement. Buyers gain flexibility in ordering single sets or scaled batches, supported by responsive logistics networks capable of air or sea freight dispatch within 72 hours post-inspection.

How to Choose Turing Machine Suppliers?

Selecting reliable suppliers requires structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance

Confirm adherence to internationally recognized quality standards such as ISO 9001, especially for manufacturers offering custom machining services or automated production lines. For export-bound equipment involving electrical systems (e.g., motor armature finishing machines), verify compliance with CE or RoHS directives to ensure compatibility with European and North American regulatory frameworks. Request test reports for critical subsystems including spindle accuracy, tool positioning repeatability, and thermal stability in continuous operation.

Production Capability Audits

Assess supplier infrastructure through verifiable metrics:

- Facility size exceeding 2,000m² for full-scale production capacity

- In-house CNC machining, welding, and assembly lines

- Dedicated R&D departments supporting customization (e.g., OEM/ODM tooling, software integration)

Cross-reference online revenue indicators and on-time delivery rates—prioritize suppliers with ≥97% fulfillment performance and response times under 4 hours to ensure operational responsiveness.

Transaction Safeguards

Utilize secure payment mechanisms such as escrow services that release funds only upon successful inspection at destination. Evaluate reorder rates as a proxy for customer satisfaction; values above 25% indicate consistent quality and service reliability. Conduct sample testing before bulk orders—benchmark cutting precision, surface finish quality, and cycle time efficiency against defined technical specifications.

What Are the Best Turing Machine Suppliers?

| Company Name | Location | Verification Status | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Min. Order Value |

|---|---|---|---|---|---|---|---|---|

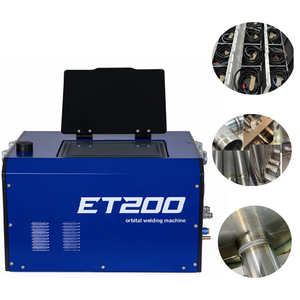

| Dalian R&C Machinery Co., Ltd. | Liaoning, CN | Multispecialty Supplier | CNC Turning Centers, High-End Lathe-Milling Machines | 75% | ≤3h | 18% | US $690,000+ | $78,775/set |

| Ningbo NIDE Tech Co., Ltd. | Zhejiang, CN | Custom Manufacturer | Armature Finishing, Rotor Die-Casting Machines | 100% | ≤11h | <15% | - | $5,000/set |

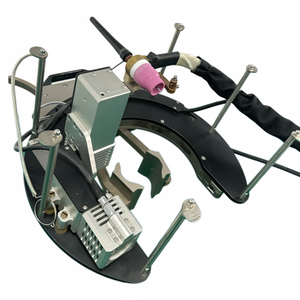

| Dongguan Turing Automation Technology Co., Ltd. | Guangdong, CN | Unverified | Cable Stripping, Mute Semi-Auto Wire Processing | 100% | ≤4h | - | - | $472/set |

| Shenzhen Da Tai Xin Intelligent Manufacturing Technology Co., Ltd. | Guangdong, CN | Unverified | High-Precision Boring, ODM Machining Services | 100% | ≤3h | 50% | US $8,000+ | $2.38/piece (MOQ: 10) |

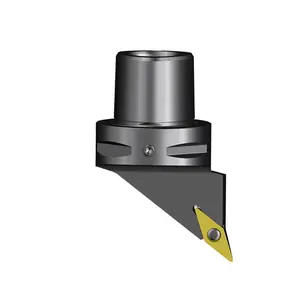

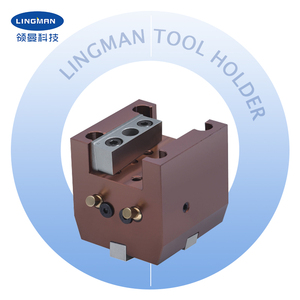

| Softool Manufacturing Co., Ltd. | Unknown, CN | Unverified | PSC Turning Tools, CNC Tool Holders | 100% | ≤3h | 28% | US $10,000+ | $89.22/piece |

Performance Analysis

Dalian R&C Machinery represents a high-capacity producer of heavy-duty CNC turning centers, though its 75% on-time delivery rate suggests potential logistical constraints. In contrast, Ningbo NIDE Tech and Dongguan Turing Automation achieve perfect on-time fulfillment, indicating robust production planning despite lower reorder rates. Notably, Shenzhen Da Tai Xin stands out with a 50% reorder rate—among the highest in the dataset—indicating strong client retention likely driven by responsive service and reliable machining output. Softool Manufacturing offers precision tooling solutions at competitive pricing, with sub-$100 entry points ideal for spare part procurement. Buyers seeking large-format CNC systems should prioritize Dalian-based suppliers, while those requiring specialized automation or component-level finishing may favor Guangdong and Zhejiang-based vendors.

FAQs

How to verify Turing machine supplier reliability?

Validate certifications (ISO 9001, CE) through official registries and request audit trails covering material sourcing, process controls, and final inspection protocols. Analyze transaction history, focusing on consistent on-time delivery (>95%) and documented after-sales support. Video factory tours can confirm in-house production capabilities versus trading company intermediation.

What is the average sampling timeline?

Standard samples for CNC tools or small machinery units are typically produced within 10–20 days. Complex automated systems (e.g., multicore wire strippers or rotor finishing lines) require 25–40 days for prototyping. Air freight adds 5–10 days for international delivery, depending on destination region.

Can suppliers ship machinery worldwide?

Yes, most established suppliers support global shipping via FOB, CIF, or DDP terms. Confirm packaging standards (export-grade wooden crates), insurance coverage, and compliance with import regulations for electrical and mechanical equipment in the target market. Sea freight is recommended for full-container loads due to cost efficiency.

Do manufacturers provide free samples?

Sample policies vary by product value and customization level. Low-cost items like turning tools may incur partial fees ($20–$50), often deductible from future orders. For high-value machinery, suppliers typically charge full sample costs (30–60% of unit price), with waivers applied upon confirmation of volume contracts.

How to initiate customization requests?

Submit detailed technical drawings, material specifications (e.g., alloy type, hardness), dimensional requirements, and functional parameters (speed, load capacity). Reputable suppliers will respond with feasibility assessments, 3D models, or CAD renderings within 72 hours and deliver prototypes within 3–5 weeks, depending on complexity.