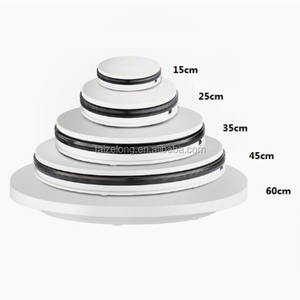

Turnable Rotating Display Table Distributor

Top sponsor listing

Top sponsor listing

1/3

1/3

0

0

1/3

1/3

1/33

1/33

1/8

1/8

1/3

1/3

1/3

1/3

1/3

1/3

1/1

1/1

1/3

1/3

1/3

1/3

1/28

1/28

1/3

1/3

0

0

1/2

1/2

1/3

1/3

1/3

1/3

1/3

1/3

About turnable rotating display table distributor

Where to Find Turntable Rotating Display Table Suppliers?

China remains the central hub for turntable rotating display table manufacturing, with key production clusters in Guangdong and Zhejiang provinces. These regions host specialized workshops and large-scale factories that combine precision engineering with cost-efficient production. Guangdong, particularly around Foshan and Dongguan, offers access to advanced metalworking and acrylic processing facilities, enabling high-volume output of motorized and manual rotation systems. Zhejiang’s Yiwu and Ningbo zones are known for lightweight, modular designs tailored for retail environments, leveraging local expertise in consumer display solutions.

The industrial ecosystems in these areas feature vertically integrated supply chains—encompassing die-casting, CNC machining, bearing assembly, and surface finishing—within tightly concentrated geographic radii. This integration reduces component lead times by up to 40% compared to decentralized manufacturing models. Buyers benefit from scalable production capacity, with standard unit lead times averaging 20–35 days for bulk orders. Localized sourcing of materials such as aluminum alloys, tempered glass, and ABS plastics contributes to 15–25% lower unit costs, while supporting customization in load capacity (5–500kg), rotation speed (0.5–6 RPM), and drive mechanisms (gear motor vs. stepper motor).

How to Choose Turntable Rotating Display Table Suppliers?

Implement structured evaluation criteria to ensure supplier reliability and product consistency:

Quality Management Standards

Confirm ISO 9001 certification as a baseline for process control. For export to regulated markets (EU, North America), verify compliance with CE marking requirements related to electrical safety (if motorized) and RoHS directives on restricted substances. Request test reports for noise levels (should not exceed 45 dB under normal operation) and continuous runtime performance (minimum 8,000-hour motor lifespan under load).

Production Capacity Assessment

Evaluate operational scale and technical capability through the following indicators:

- Minimum factory footprint of 2,000m² to support batch production

- In-house machining capabilities including CNC lathing, laser cutting, and injection molding

- Dedicated quality inspection stations with torque and balance testing equipment

Cross-reference declared monthly output (typically 1,000–5,000 units among mid-tier suppliers) with actual shipment histories to validate scalability.

Procurement Risk Mitigation

Utilize secure payment terms such as irrevocable LC or third-party escrow until post-delivery acceptance. Prioritize suppliers with documented export experience to your target market, particularly those familiar with packaging standards for fragile components (e.g., acrylic tops). Conduct pre-shipment inspections via independent agencies to verify dimensional accuracy, rotational smoothness, and finish quality. Prototype sampling is critical—request functional units before committing to MOQs exceeding 100 pieces.

What Are the Best Turntable Rotating Display Table Suppliers?

No supplier data is currently available for turntable rotating display table distributors. Market research indicates active manufacturers in China’s Pearl River Delta and Yangtze River Delta regions, but verifiable operational metrics—including facility size, delivery performance, and customer reorder rates—are limited at this time.

Performance Analysis

In the absence of quantified supplier profiles, procurement professionals should focus on qualifying manufacturers through direct engagement. Emphasis should be placed on technical documentation transparency, responsiveness to engineering inquiries, and willingness to provide factory audit access. Early-stage due diligence—such as requesting CAD drawings, material certifications, and sample testing protocols—can mitigate risks associated with unverified claims. As the market consolidates, suppliers demonstrating consistent on-time delivery (>97%), robust after-sales service, and investment in R&D are expected to emerge as leaders.

FAQs

How to verify turntable rotating display table supplier reliability?

Audit suppliers using a combination of documentary verification and physical validation. Confirm ownership of manufacturing assets through utility bills or land registry records. Review business licenses and cross-check export records via customs databases where accessible. Require video walkthroughs of production lines, focusing on assembly processes and QC checkpoints.

What is the average sampling timeline?

Standard samples take 7–14 days to produce, depending on complexity. Motorized variants with custom control interfaces may require 20–25 days. Air freight adds 5–10 days for international delivery. Expect to cover full sample costs unless prior order commitments are established.

Can suppliers ship globally?

Yes, most established manufacturers offer FOB, CIF, and DDP shipping terms. Confirm whether packaging meets ISTA 3A standards for drop and vibration resistance, especially for glass-topped models. Sea freight is recommended for container loads to optimize per-unit logistics costs.

Do suppliers offer free samples?

Free samples are uncommon. Some suppliers offset sample fees against future bulk orders (typically MOQ ≥ 200 units). Standard charges range from 1.5x to 3x the unit price, reflecting material and labor inputs.

How to initiate customization requests?

Submit detailed specifications including diameter (ranging 200mm–2000mm), weight capacity, power source (AC/DC/battery), rotation direction (unidirectional/reversible), and interface controls (remote/wireless/timer). Reputable suppliers will respond with engineering proposals, 3D renderings, and prototype timelines within 5–7 business days.