Types Of Api

Top sponsor listing

Top sponsor listing

1/16

1/16

1/3

1/3

1/1

1/1

1/17

1/17

CN

CN

1/13

1/13

1/1

1/1

1/3

1/3

1/3

1/3

1/3

1/3

1/2

1/2

1/3

1/3

1/20

1/20

1/3

1/3

1/1

1/1

1/15

1/15

0

0

1/1

1/1

1/3

1/3

About types of api

Where to Find API Equipment Suppliers?

China remains a central hub for manufacturing API-compliant oilfield and industrial equipment, with key production clusters in Shandong, Tianjin, and Jiangsu provinces. Shandong is home to vertically integrated facilities specializing in OCTG (Oil Country Tubular Goods), drilling rigs, and mud pumps, supported by regional steel supply chains that reduce material costs by 15–20%. Dongying and Qingdao serve as focal points for API-certified component production, offering streamlined logistics via port access and mature supplier ecosystems.

Tianjin and Nantong-based manufacturers focus on precision-forged valves, elevators, and sucker rod systems under API 6A, 7K, and 8C standards. These regions benefit from concentrated engineering talent and proximity to metallurgical processing centers, enabling tighter tolerances and faster prototyping. The clustering effect allows suppliers to maintain lead times of 30–45 days for standard orders, with scalability for bulk shipments exceeding 5-ton lots. Buyers gain access to consolidated networks encompassing raw material sourcing, heat treatment, threading, and non-destructive testing—all within localized industrial zones.

How to Choose API Equipment Suppliers?

Selecting reliable partners requires structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Standards

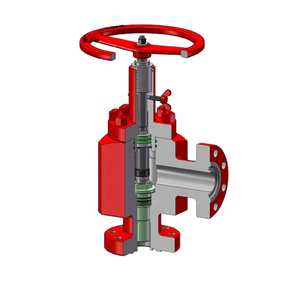

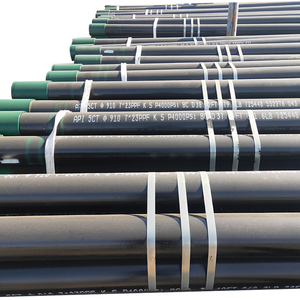

Confirm adherence to relevant API specifications (e.g., API 5CT for casing/tubing, API 6A for wellhead equipment, API 7K for drill stem tools). While formal ISO 9001 certification is not explicitly stated in available data, consistent on-time delivery rates above 95% suggest established quality management systems. For critical applications, request test reports covering hydrostatic pressure testing, tensile strength, and thread accuracy (NPT or premium connections).

Production Capacity Verification

Assess infrastructure maturity through measurable indicators:

- Minimum monthly output capacity of 5+ tons for seamless pipe products

- In-house capabilities including hot/cold rolling, welding, threading, and surface treatments (e.g., galvanization)

- Customization support for diameter, length, wall thickness, material grade (PLS1, PLS2), and end finishes

Cross-reference product listings with order fulfillment metrics—suppliers reporting 100% on-time delivery are more likely to have stable production scheduling and inventory control.

Procurement Risk Mitigation

Implement safeguards before full-scale ordering:

- Require sample validation for dimensional accuracy and material composition prior to bulk production

- Use secure payment terms with milestone-based disbursements tied to shipment milestones

- Analyze reorder rates as a proxy for customer satisfaction—rates above 30% indicate strong post-sale performance

- Verify responsiveness (≤2-hour average reply time) to ensure real-time issue resolution during production

What Are the Leading API Equipment Suppliers?

| Company Name | Location | Main Product Lines | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|

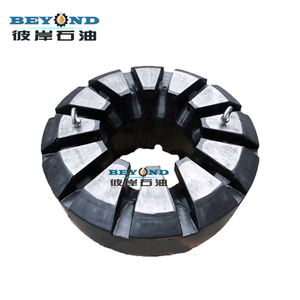

| Shandong Beyond Petroleum Equipment Co., Ltd. | Shandong, CN | Mud Pump, Drilling Rig, Shale Shaker, Mining Parts | 100% | ≤2h | 33% | US $30,000+ | Material, size, color, logo, packaging, flange type |

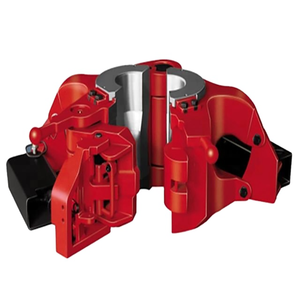

| Dongying Kangya Petroleum Equipment Co., Ltd. | Shandong, CN | API 6A FC Slab Gate Valve, API 16A Cameron-Type BOP, API 5CT Tubing | 95% | ≤1h | <15% | US $1,400,000+ | Color, material, size, logo, packaging |

| Shandong Lurun Trading Co., Ltd. | Shandong, CN | API 5CT Casing & Drill Pipe, Seamless Tubes | 100% | ≤1h | 50% | US $490,000+ | Material, diameter, length, thickness, coating, threading, packaging |

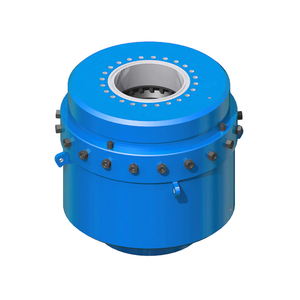

| Tianjin Soright Technology Development Co., Ltd. | Tianjin, CN | Sucker Rod Pump, Production Casing, Centralizers | 100% | ≤2h | <15% | US $1,000+ | Limited customization per listing |

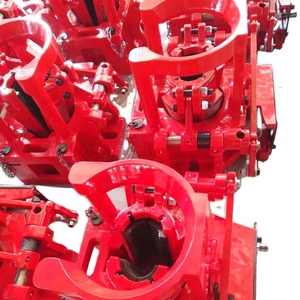

| Nantong Strong Petroleum Technology Co., Ltd. | Jiangsu, CN | API 7K Drill Elevators, API 8C Handling Tools | 100% | ≤2h | 25% | US $5,000+ | Size, configuration, labeling |

Performance Analysis

Shandong-based suppliers dominate in both volume output and customization depth, particularly for tubular goods and drilling machinery. Shandong Lurun stands out with a 50% reorder rate—indicating high customer retention—supported by extensive material and dimensional flexibility for API 5CT products. Dongying Kangya reports the highest online revenue (over US $1.4M), reflecting strong market penetration in forged valve and BOP segments despite a lower reorder rate.

Suppliers achieving 100% on-time delivery—Shandong Beyond, Shandong Lurun, Tianjin Soright, and Nantong Strong—demonstrate reliable operational execution. Fast response times (≤1 hour) at Dongying Kangya and Shandong Lurun enhance communication efficiency, critical for resolving technical queries during order processing. Buyers seeking customized OCTG solutions should prioritize Shandong Lurun for its broad parameter adjustability, while those requiring specialized handling tools may favor Nantong Strong’s API 7K/8C product range.

FAQs

How to verify API compliance in supplier products?

Request documentation including material test reports (MTRs), thread inspection records, and hydrostatic test results. Confirm alignment with specific API standards referenced in product titles (e.g., API 5CT, API 6A). Independent third-party inspection services can validate conformance at origin.

What are typical MOQs for API equipment?

Minimum order quantities vary by product type: seamless pipes and tubing typically require 5 tons or 100 pieces; forged valves and BOP components often have MOQs of 1 set or 1 piece. Sample orders may be available at higher per-unit pricing.

Do suppliers offer customization for API-certified parts?

Yes, most suppliers listed provide customization across material grade, dimensions, coatings, threading types (e.g., NPT), and branding elements like logos and labels. Engineering modifications beyond standard API designs require direct consultation and feasibility assessment.

What is the average lead time for API equipment?

Standard orders typically ship within 30–45 days after deposit confirmation. Custom-fabricated items or large-volume OCTG shipments may extend to 60 days depending on complexity and factory workload.

Can suppliers handle international shipping?

Yes, all listed companies engage in export activities with documented global sales. Confirm Incoterm preferences (FOB, CIF) and coordinate with freight forwarders for customs clearance, especially for regulated oilfield equipment entering North American or EU markets.