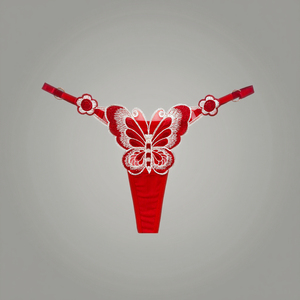

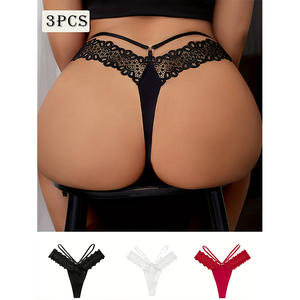

Underwear With Strings

Top sponsor listing

Top sponsor listing

1/3

1/3

1/3

1/3

1/3

1/3

1/28

1/28

1/2

1/2

1/10

1/10

1/3

1/3

1/3

1/3

1/26

1/26

1/40

1/40

1/3

1/3

0

0

1/8

1/8

1/3

1/3

0

0

About underwear with strings

Where to Find Underwear with Strings Suppliers?

China remains the central hub for intimate apparel manufacturing, with key production clusters in Guangdong, Zhejiang, and Jiangsu provinces. Guangdong, particularly around Guangzhou and Shenzhen, hosts a high concentration of lingerie exporters specializing in fashion-forward designs, including underwear with strings. These regions benefit from mature textile ecosystems, offering integrated access to fabric mills, dyeing facilities, and trim suppliers within 30–50km radii.

The industrial clusters support rapid prototyping and scalable production, with many factories operating vertically integrated workflows—from knitting and lace fabrication to cut-and-sew assembly. This localization reduces lead times by up to 40% compared to offshore alternatives. Buyers typically experience 25–35 days for sample development and 30–45 days for bulk order fulfillment, depending on customization level. Labor efficiency, combined with automated sewing lines in larger facilities, enables competitive pricing—production costs are generally 20–30% lower than in South Asian or Eastern European markets.

How to Choose Underwear with Strings Suppliers?

Implement structured evaluation criteria to ensure product quality, compliance, and supply chain reliability:

Quality & Compliance Verification

Confirm adherence to international textile standards such as ISO 9001 for quality management and OEKO-TEX® Standard 100 for harmful substance control. For EU and North American markets, verify REACH and CPSIA compliance, particularly for dyes and elastic components. Request test reports for colorfastness (minimum 3–4 on ISO 105-B02), pilling resistance, and seam strength.

Production Capacity Assessment

Evaluate operational scale and technical capability through the following benchmarks:

- Minimum 3,000m² factory area for consistent volume output

- Dedicated sampling department with turnaround under 7 days

- In-house design team supporting custom patterns, trims, and string configurations

Cross-reference monthly output capacity (typically 50,000–200,000 units) with historical order data to assess scalability and inventory turnover.

Procurement Safeguards

Utilize secure transaction methods such as third-party inspection services (e.g., SGS or TÜV) prior to shipment. Review supplier track records via verified trade histories, focusing on dispute resolution performance and reorder rates. Pre-production sampling is critical—evaluate fit, fabric hand feel, stitching density (minimum 12 stitches per inch), and attachment strength of strings and straps before approving mass production.

What Are the Best Underwear with Strings Suppliers?

No supplier data is currently available for this product category.

Performance Analysis

In the absence of specific supplier profiles, buyers should prioritize manufacturers with demonstrable export experience to Western markets, particularly those with portfolios showcasing lace-trimmed styles, adjustable string detailing, and seamless construction. Factories located in Guangdong province tend to offer faster communication response times (often under 4 hours) and greater familiarity with EU/US sizing and labeling requirements. Focus on suppliers reporting on-time delivery rates above 95%, backed by documented quality control checkpoints at cutting, sewing, and final inspection stages. For private label or custom collections, confirm digital design submission capabilities and pattern-making expertise during initial engagement.

FAQs

How to verify underwear with strings supplier reliability?

Validate business licenses and export credentials through official registries. Request audit trails covering raw material sourcing, in-process quality checks, and finished garment inspections. Prioritize suppliers who provide batch-specific lab testing documentation and allow remote or on-site factory audits.

What is the average sampling timeline?

Standard samples take 5–7 days; customized designs with unique lace, prints, or string placements require 10–14 days. Air shipping adds 5–8 days for international delivery. Expedited service (3–5 days) may be available at a premium.

What are typical MOQs and pricing?

MOQs range from 300–1,000 units per style/colorway for mid-sized factories. Larger exporters may require 2,000+ units but offer unit prices 15–25% lower. Basic cotton-blend string briefs start at $1.20–$2.50/unit FOB, while lace-combination styles range from $2.80–$5.00/unit, depending on complexity.

Can suppliers accommodate custom packaging and labeling?

Yes, most established manufacturers support branded packaging, polybag labeling, swing tags, and care instructions in multiple languages. Minimum runs for custom packaging typically start at 1,000 units.

How to initiate customization requests?

Submit detailed tech packs including flat sketches, measurements, fabric swatches, string placement, and trim specifications. Reputable suppliers will return digital mockups within 48 hours and physical prototypes within two weeks. Confirm revision policies and tooling fees (if applicable) upfront.