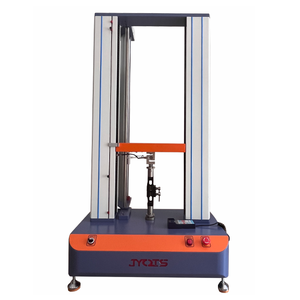

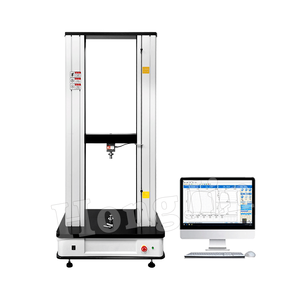

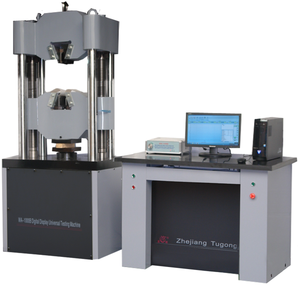

Universal Testing Machine

Top sponsor listing

Top sponsor listing

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/2

1/2

1/2

1/2

1/3

1/3

1/3

1/3

0

0

0

0

1/10

1/10

1/15

1/15

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

About universal testing machine

Where to Find Universal Testing Machine Suppliers?

China remains the global epicenter for universal testing machine (UTM) manufacturing, with concentrated supplier clusters in Shandong and Guangdong provinces driving innovation and cost efficiency. Shandong, particularly Jinan, hosts a high density of specialized test equipment manufacturers leveraging proximity to metallurgical and construction material industries, enabling rapid prototyping and application-specific customization. Guangdong’s Dongguan and Foshan regions offer advanced electronics integration and precision machining infrastructure, supporting high-accuracy digital and computer-controlled UTM systems.

These industrial hubs benefit from vertically integrated supply chains—spanning load cell fabrication, frame casting, software development, and calibration services—reducing component lead times by 25–40%. The regional ecosystem supports scalable production, with typical delivery windows ranging from 15 to 30 days for standard configurations. Buyers gain access to flexible MOQs (often as low as one set), competitive pricing influenced by localized production economies, and strong technical support for both mechanical and software-based system integration.

How to Choose Universal Testing Machine Suppliers?

Effective supplier selection requires structured evaluation across three critical domains:

Technical Compliance & Calibration Standards

Verify adherence to international standards such as ISO 7500-1 (for static tensile/compression testing) and ASTM E4. Look for suppliers providing certified calibration reports traceable to NIST or CNAS. CE marking is essential for European market compliance, while ISO 9001 certification indicates a formal quality management system. Confirm software compatibility with industry-standard data acquisition and analysis protocols.

Production and Engineering Capability

Assess core competencies through verifiable metrics:

- Minimum factory area of 2,000m² to ensure dedicated assembly and testing zones

- In-house engineering teams capable of customizing load frames (ranging from 1kN to 1000kN)

- Integration of digital control systems, servo-hydraulic actuators, and multi-axis testing functionalities

Cross-reference product listings with on-time delivery performance (target ≥90%) and response time (ideally ≤2 hours) to gauge operational responsiveness.

Transaction and Quality Assurance

Prioritize suppliers offering documented post-sale support, including installation guidance, operator training, and remote diagnostics. Utilize secure transaction channels where payment protection aligns with order milestones. Conduct sample testing to validate accuracy, repeatability, and software stability under real-world lab conditions before scaling procurement.

What Are the Best Universal Testing Machine Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range (Min-Max Price) |

|---|---|---|---|---|---|---|---|

| Jinan Fokstest Instrument Co., Ltd. | Shandong, CN | Testing Equipment, Hardness Testers, Tensile Testing Machines, Microscopes | US $10,000+ | 100% | ≤2h | <15% | $200–$5,100 |

| Guangdong Hongyu International Trade Co., Ltd. | Guangdong, CN | Tensile Testing Machine, Compression Tester, Viscometer, Chromatograph | US $100,000+ | 100% | ≤2h | <15% | $200–$4,021 |

| Jinan Zhongchuang Industry Test Systems Co., Ltd. | Shandong, CN | Tensile Testing Machine, Compression Tester, Hardness Testers | US $50,000+ | 90% | ≤2h | <15% | $2,100–$9,200 |

| Dongguan Zhongzhi Times Test Equipment Co., Ltd. | Guangdong, CN | Tensile Testing Machine, Compression Tester | - | 100% | ≤1h | - | $1,000–$9,300 |

| Hangzhou Yueke Instrument Co., Ltd. | Zhejiang, CN | Compression Tester, Soil Tester, Tensile Testing Machine, Viscometer | US $7,000+ | 100% | ≤1h | <15% | $690–$20,000 |

Performance Analysis

Suppliers from Shandong, such as Jinan Fokstest and Jinan Zhongchuang, emphasize robust mechanical design and higher-load-capacity models, catering to metal and construction materials testing. Guangdong-based vendors like Guangdong Hongyu and Dongguan Zhongzhi focus on compact, single-column digital systems ideal for plastics, rubber, and R&D labs. Hangzhou Yueke stands out with a broad price range, indicating flexibility in serving both entry-level and high-end industrial clients.

All top-tier suppliers maintain 100% on-time delivery except Jinan Zhongchuang (90%), suggesting reliable logistics execution across the sector. Response times are consistently fast (≤2h), with two suppliers achieving sub-one-hour averages—critical for timely technical clarification. Reorder rates below 15% indicate predominantly new customer acquisition, which may reflect aggressive pricing or niche market positioning rather than long-term client retention challenges.

FAQs

How to verify universal testing machine supplier reliability?

Cross-validate certifications (ISO 9001, CE) through official registries. Request factory audit reports or video tours confirming in-house production capabilities. Evaluate technical documentation quality, including calibration certificates, user manuals, and software interface demos.

What is the typical lead time for universal testing machines?

Standard models ship within 15–25 days after order confirmation. Custom configurations involving specialized grips, environmental chambers, or non-standard load capacities may extend lead times to 35–45 days, depending on software and hardware integration complexity.

Do suppliers support customization?

Yes, most suppliers offer frame customization (dual/single column), load capacity adjustments (from 1kN to 1000kN), and software branding or language localization. Provide detailed technical specifications—including test standards, sample dimensions, and data output requirements—for accurate quoting.

What are common MOQ and pricing structures?

MOQ is typically 1 set, facilitating pilot purchases and lab upgrades. Pricing varies significantly based on control type: basic digital display units start around $690, while computerized electro-hydraulic servo systems exceed $20,000. Bulk orders (5+ units) often qualify for tiered discounts and reduced shipping costs.

How are universal testing machines packaged and shipped?

Machines are crated in wooden enclosures with foam cushioning and moisture barriers. Most suppliers offer FOB terms, with sea freight recommended for full-container loads due to equipment weight (200–3,000 kg). Air freight is viable for urgent single-unit deliveries but incurs higher costs.