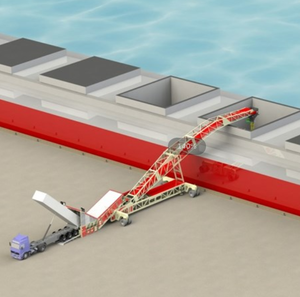

Unloading Bulk Carrier

CN

CN

1/20

1/20

1/24

1/24

About unloading bulk carrier

Where to Find Unloading Bulk Carrier Suppliers?

China remains the central hub for industrial-scale unloading bulk carrier manufacturing, with key production clusters concentrated in Henan and Guangdong provinces. These regions host vertically integrated facilities specializing in material handling systems, port logistics equipment, and heavy-duty cargo transfer machinery. Henan’s engineering ecosystem supports large-capacity crane and dumper production, leveraging proximity to steel suppliers and inland ports. Guangdong’s coastal access enables streamlined export logistics, particularly for mobile ship unloaders and automated bulk bag systems serving global maritime terminals.

The sector benefits from mature supply chains that integrate structural fabrication, hydraulic system assembly, and control panel integration within compact geographic zones. This localization reduces component lead times and supports rapid prototyping for customized configurations. Buyers can expect standard production lead times of 45–60 days for complex continuous ship unloaders, while modular systems like bulk bag unloaders may be available in as little as 30 days. Cost efficiency is further enhanced by economies of scale, with Chinese manufacturers offering 20–35% lower unit pricing compared to European or North American equivalents for comparable specifications.

How to Choose Unloading Bulk Carrier Suppliers?

Selecting a reliable supplier requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Design Expertise

Verify adherence to international safety and performance standards such as ISO 9001 for quality management and CE marking for mechanical and electrical systems. For marine applications, confirm compatibility with SOLAS and IMO guidelines where applicable. Evaluate design documentation for load capacity, material flow rates (measured in t/h), and environmental resilience—especially for outdoor port installations exposed to corrosion.

Production Capability Assessment

Assess infrastructure maturity through objective metrics:

- Minimum factory area exceeding 5,000m² for full-scale equipment manufacturing

- In-house engineering teams capable of delivering 3D modeling and finite element analysis (FEA)

- Integrated welding, machining, and assembly lines to ensure consistency and traceability

Cross-reference these capabilities with on-time delivery performance; suppliers maintaining ≥95% punctuality are more likely to meet project-critical timelines.

Transaction Security & Quality Assurance

Utilize secure payment mechanisms such as escrow services tied to shipment milestones. Prioritize suppliers offering pre-shipment inspection protocols, including load testing reports and video verification of functional trials. Request sample units when feasible—particularly for custom configurations—to validate structural integrity and operational smoothness before scaling procurement.

What Are the Best Unloading Bulk Carrier Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| NAM SON MECHANICAL MANUFACTURE CO., LTD | Hanoi, VN | Data Unavailable | Data Unavailable | Data Unavailable | Pending | ≤4h | Not Rated | Pending |

| Huizhou Xiewei Machinery Equipment Co., Ltd. | Guangdong, CN | Data Unavailable | Data Unavailable | Data Unavailable | 100% | ≤1h | Not Rated | Pending |

| Henan Province Modern Crane Co., Ltd. | Henan, CN | Data Unavailable | Data Unavailable | Data Unavailable | 100% | ≤2h | Not Rated | Pending |

| Nucleon (xinxiang) Crane Co., Ltd. | Henan, CN | Data Unavailable | Data Unavailable | Data Unavailable | 100% | ≤2h | Not Rated | Pending |

| MANUFACTURING AIR-BLOWN MATERIALS TAY DO CO.,LTD | Vietnam | Data Unavailable | Data Unavailable | Data Unavailable | Pending | ≤11h | Not Rated | Pending |

Performance Analysis

Suppliers based in Henan demonstrate strong responsiveness and proven delivery reliability, with three companies reporting 100% on-time fulfillment. Huizhou Xiewei stands out for sub-hour response times, indicating robust customer service infrastructure despite limited public data on facility size. NAM SON MECHANICAL offers multi-functional continuous ship unloaders priced between $50,000–$225,000 per set, targeting mid-to-large-scale port operations. In contrast, Tay Do Co., Ltd. focuses on high-capacity vacuum-based cement unloading systems, with one model listed at $1 million per gross unit, suggesting specialization in large-volume industrial transfers.

Diverse product ranges reflect segmentation: mobile grain unloaders and dry bulk cargo systems dominate offerings under $100,000, while screw-type and vacuum conveyors serve niche markets requiring dust-free transfer. Buyers seeking customization should prioritize suppliers providing detailed technical drawings and willingness to conduct virtual factory audits.

FAQs

How to verify unloading bulk carrier supplier reliability?

Cross-check claimed certifications with issuing bodies and request copies of test reports for critical components such as grabs, booms, and conveyor drives. Analyze response consistency and technical depth in communications. Favor suppliers who provide factory walkthrough videos and real-time production updates.

What is the typical MOQ and pricing range?

Standard MOQ is 1 set across all major suppliers. Pricing varies significantly by type: bulk bag unloaders start at $1,000–$2,000, truck and container dumpers range from $40,000–$92,000, while continuous ship unloaders and marine cranes typically cost $50,000–$200,000 per unit. High-capacity cement transfer systems may exceed $1 million for complete installations.

Are customization options available?

Yes, most suppliers offer tailored solutions for capacity, power source (electric/diesel), discharge height, and material compatibility. Customized bulk bag unloaders and hydraulic truck dumpers are commonly engineered to client specifications, with lead times extending by 15–30 days depending on complexity.

Can suppliers handle international shipping?

Yes, experienced manufacturers manage export logistics via FOB or CIF terms. Confirm packaging standards (e.g., seaworthy crates, corrosion protection), and ensure compliance with destination port regulations for heavy machinery imports. Sea freight is standard for full-container loads due to size and weight constraints.

What materials are used in construction?

Structural components are typically fabricated from carbon steel (Q235 or Q345) with anti-corrosion coatings for outdoor use. Stainless steel (SUS304/SUS316) is specified for food-grade or chemical applications, particularly in bulk bag unloader systems handling sensitive powders or agricultural chemicals.