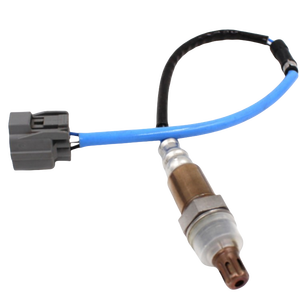

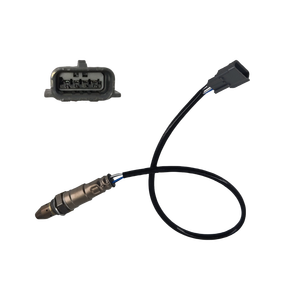

Upstream O2 Sensor

Top sponsor listing

Top sponsor listing

1/27

1/27

1/3

1/3

0

0

1/23

1/23

0

0

0

0

1/3

1/3

0

0

1/24

1/24

1/3

1/3

1/2

1/2

1/10

1/10

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/3

1/3

About upstream o2 sensor

Where to Find Upstream O2 Sensor Suppliers?

China remains the dominant hub for upstream oxygen (O2) sensor manufacturing, with Guangzhou emerging as a key industrial cluster due to its concentrated automotive electronics supply chain. The city hosts multiple specialized suppliers leveraging vertically integrated production networks—from precision machining and ceramic element fabrication to final calibration—enabling competitive pricing and rapid scalability. These ecosystems benefit from proximity to Tier-1 component manufacturers and logistics gateways, reducing lead times and facilitating just-in-time delivery models.

Suppliers in this region typically operate within mature export-oriented frameworks, supporting global aftermarket demand across North America, Europe, and Southeast Asia. Average monthly production capacity among verified suppliers exceeds 50,000 units, with standard lead times ranging from 7–15 days for stocked configurations. Localization of materials such as zirconia electrolytes, platinum electrodes, and stainless-steel housings contributes to a 20–30% cost advantage over Western or Eastern European producers. Buyers also gain access to flexible MOQs, often starting at 1–4 pieces for testing and scaling to container-level volumes.

How to Choose Upstream O2 Sensor Suppliers?

Effective supplier selection requires structured evaluation across technical, operational, and transactional dimensions:

Quality & Compliance Verification

Confirm adherence to ISO 9001 standards as a baseline for quality management. For regulated markets, ensure compatibility with OBD-II (On-Board Diagnostics) requirements and verify performance alignment with OEM specifications (e.g., response time ≤100ms, operating temperature range 300°C–800°C). Request test reports on signal stability, cross-sensitivity resistance, and lifespan validation under simulated exhaust conditions.

Production & Technical Capability Assessment

Evaluate supplier infrastructure based on the following indicators:

- In-house sensor calibration and aging test chambers

- Surface-mount technology (SMT) lines for heater circuit assembly

- Ceramic sintering and laser welding capabilities

Cross-reference declared output with on-time delivery rates; prioritize suppliers maintaining ≥96% fulfillment consistency. A reorder rate above 30% indicates strong customer retention and product reliability.

Customization & Transaction Security

Assess flexibility for branding, packaging, and electrical configuration adjustments. Leading suppliers offer customization of wire length, connector type, thread size, and labeling. Demand secure payment terms via third-party assurance mechanisms. Validate compatibility through sample testing—benchmark against known OEM units for voltage output (0.1–0.9V swing) and switching frequency before mass procurement.

What Are the Best Upstream O2 Sensor Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | MOQ Range | Customization Options |

|---|---|---|---|---|---|---|---|

| Guangzhou Super Technology Co., Ltd. | Auto Sensors, Ignition Coils, Fuel Filters, Injection Valves | US $860,000+ | 99% | 22% | ≤3h | 4–10 pcs | Color, material, logo, packaging, label, graphic |

| Guangzhou Bineng Business Co., Ltd. | Oxygen Sensors, Auto Parts, Engine Components | US $290,000+ | 96% | 22% | ≤2h | 4–10 pcs | Engraving, laser lettering, design, compatibility, original packing |

| Guangzhou Hanzhuang Automotive Electronics Technology Co., Ltd. | Auto Sensors, Ignition Coils, Fuel Pumps, Bearings | US $50,000+ | 93% | 15% | ≤4h | 1–5 pcs | Limited customization (product data not fully disclosed) |

| Guangzhou Gezan Sensor Co., Ltd. | Oxygen Sensors, Lambda Sensors, Automotive Electronics | US $590,000+ | 99% | 47% | ≤2h | 20 pcs | Pinout, color, material, size, model number, schematic, packaging |

| Beijing Changxing Jiuzhou Automobile Service Co., Ltd. | Auto Sensors, Catalytic Converters, LED Headlights | US $5,000+ | 100% | 37% | ≤1h | 1–30 pcs | Not specified |

Performance Analysis

Guangzhou Gezan Sensor Co., Ltd. stands out with a 47% reorder rate—the highest in the dataset—indicating strong buyer satisfaction and consistent product performance. Combined with 99% on-time delivery and sub-2-hour response times, it demonstrates robust operational efficiency despite a higher MOQ of 20 pieces. Guangzhou Super Technology leads in revenue volume (US $860,000+), suggesting extensive market reach and diversified product offerings. Beijing-based Changxing Jiuzhou achieves perfect delivery compliance and fastest response times (≤1h), making it ideal for urgent procurement cycles, though its lower online revenue suggests niche-scale operations. Buyers seeking low MOQs can consider Hanzhuang or Changxing Jiuzhou, both offering single-piece minimums for prototyping or small batches.

FAQs

How to verify upstream O2 sensor supplier reliability?

Cross-check quality claims with documented testing procedures for heater circuit integrity, lambda accuracy, and contamination resistance. Review supplier transaction history, focusing on dispute resolution records and repeat order frequency. Prioritize companies with multispecialty verification and transparent product listings including technical diagrams and material specifications.

What is the typical sampling timeline for upstream O2 sensors?

Standard samples are typically shipped within 3–7 days. Customized versions requiring specific connectors or wiring harnesses may take 10–14 days. Air freight adds 5–7 days for international delivery. Expect partial or full sample fees, which are often credited toward future bulk orders.

Do suppliers support global shipping and customs clearance?

Yes, most established suppliers have experience exporting under FOB, CIF, or DDP terms. Confirm HS code classification (typically 9029.20) and ensure proper documentation for import compliance, especially in regions with strict emissions equipment regulations such as the EU and USA.

Are free samples available for upstream oxygen sensors?

Free samples are uncommon but negotiable, particularly for high-volume prospects. Some suppliers waive costs after placing a confirmed order. Standard practice involves charging 50–100% of unit cost for sampling, refundable upon contract execution.

How to initiate customization for upstream O2 sensors?

Provide detailed technical requirements: OEM reference numbers, connector type (1–4 wires), thread diameter (M12, M18, etc.), cable length, and calibration protocol. Reputable suppliers will respond with compatibility confirmation, CAD schematics, or pinout diagrams within 24–48 hours.