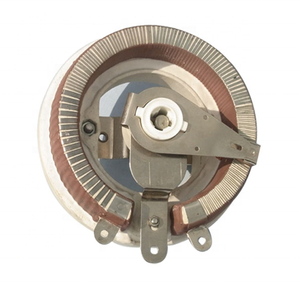

Variable Resistor

1/33

1/33

1/46

1/46

1/3

1/3

1/27

1/27

0

0

1/3

1/3

1/3

1/3

1/27

1/27

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/41

1/41

1/20

1/20

1/3

1/3

1/3

1/3

1/3

1/3

About variable resistor

Where to Find Variable Resistor Suppliers?

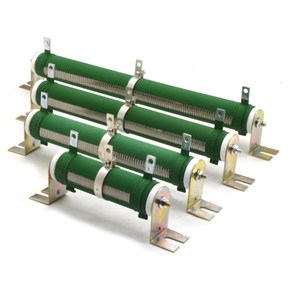

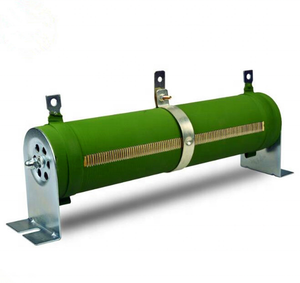

China remains the central hub for variable resistor manufacturing, with key production clusters in Guangdong, Jiangsu, and Hong Kong offering specialized capabilities. Shenzhen-based suppliers leverage proximity to electronics supply chains and export infrastructure, enabling rapid component integration and global distribution. Changzhou and Huizhou facilities focus on high-volume potentiometer and trimmer resistor production, benefiting from vertically integrated processes that reduce unit costs by 20–35% compared to Western alternatives.

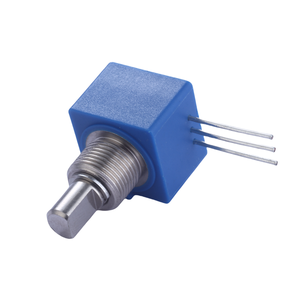

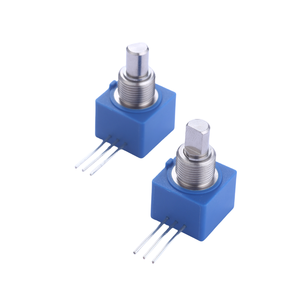

These industrial zones support mature ecosystems where material sourcing, precision winding, housing fabrication, and quality testing occur within tightly coordinated networks. Suppliers typically operate automated assembly lines capable of producing over 1 million units monthly, particularly for rotary and trimmer potentiometers. Buyers benefit from scalable output, with standard lead times averaging 15–25 days for bulk orders and localized logistics reducing shipping delays. The region’s dominance in consumer electronics and industrial controls ensures consistent innovation in materials (e.g., carbon film, wirewound alloys) and compact form factors.

How to Choose Variable Resistor Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical & Quality Compliance

Verify adherence to international standards such as IEC 60062 for resistance coding and RoHS for hazardous substance restrictions. For industrial or automotive applications, confirm compliance with AEC-Q200 stress test criteria. Request test reports for temperature coefficient stability, contact resistance variation, and lifecycle endurance (typically 5,000–500,000 rotation cycles).

Production Capacity Assessment

Evaluate supplier infrastructure based on:

- Monthly output capacity exceeding 500,000 units for high-volume procurement

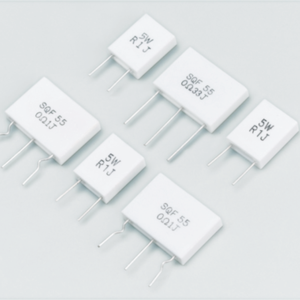

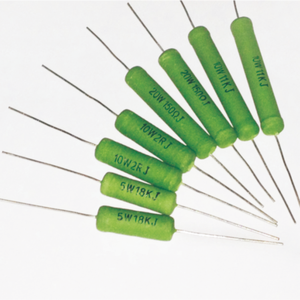

- In-house capability for wirewound coil winding, resistive track printing, and metal/aluminum housing fabrication

- Availability of laser trimming and automated calibration systems for precision tuning

Cross-reference delivery performance (target ≥95%) with response time (ideally ≤3 hours) to assess operational responsiveness.

Customization & Transaction Security

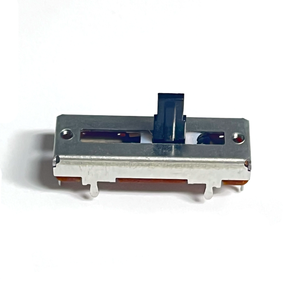

Prioritize suppliers offering configurable parameters including taper type (linear/logarithmic), shaft diameter, resistance range (1kΩ–1MΩ), and power rating (0.5W–50W). Confirm packaging, labeling, and branding customization options. Utilize secure payment mechanisms and verify order history through documented transaction volumes. Pre-shipment inspection and sample validation are critical—test at least three units per batch for electrical consistency and mechanical durability.

What Are the Best Variable Resistor Suppliers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Main Product Focus | Min. Order Flexibility |

|---|---|---|---|---|---|---|---|---|

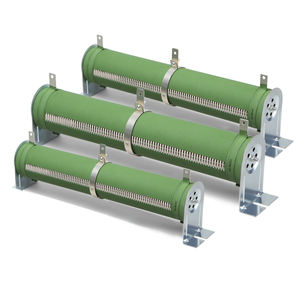

| Shenzhen Jianhong Jitai Technology Co., Ltd. | Guangdong, CN | Custom Manufacturer | US $20,000+ | 100% | ≤3h | 21% | Wirewound Power Resistors, Elevator Braking Units | 1 piece/set |

| Changzhou Kennon Electronics Co., Ltd. | Jiangsu, CN | Custom Manufacturer | US $80,000+ | 100% | ≤4h | 15% | Trimmer Potentiometers, Precision Adjusters | 1,000–20,000 pieces |

| YU WAH (HK) LIMITED | Hong Kong | - | US $30,000+ | 100% | ≤1h | 16% | Rotary Potentiometers, Carbon Film Trimmers | 5,000 pieces |

| POLYSHINE HOLDINGS LIMITED | Hong Kong | Custom Manufacturer | US $10,000+ | 95% | ≤1h | <15% | Audio Potentiometers, Dual-Shaft Controls | 1–10 pieces |

| Shimeng Electronic (Huizhou) Co., LTD. | Huizhou, CN | - | Not disclosed | 100% | ≤9h | Not available | Adjustable Aluminum-Housed Resistors | 10–100 pieces |

Performance Analysis

Shenzhen Jianhong Jitai and Changzhou Kennon lead in engineering-driven customization, supporting industrial-grade power resistors and precision trimmers with verified manufacturing status. YU WAH (HK) LIMITED excels in responsiveness (≤1h average reply) and offers competitive pricing for carbon-film rotary types. POLYSHINE stands out for low MOQs, enabling prototyping and small-batch procurement. Shimeng Electronic provides cost-effective solutions with flexible ordering but limited reorder metrics. Suppliers with US $30,000+ annual online revenue demonstrate market validation and consistent export activity. Prioritize partners with documented customization workflows and proven delivery reliability for mission-critical applications.

FAQs

How to verify variable resistor supplier reliability?

Cross-check certifications (ISO 9001, RoHS) and request product compliance documentation. Analyze supplier performance data including on-time delivery rate, response time, and reorder frequency. Conduct factory audits via video tours to confirm production lines and quality control stations.

What is the typical sampling timeline?

Standard samples ship within 7–14 days. Custom configurations (e.g., non-standard tapers or housings) may require 20–30 days. Expect additional 5–10 days for international express delivery.

Can suppliers accommodate small orders?

Yes, several suppliers offer MOQs as low as 1 piece for select models (e.g., audio potentiometers). High-volume items like trimmer resistors typically require 1,000–5,000 units. Negotiate pricing tiers based on volume commitments.

Do manufacturers provide free samples?

Sample policies vary. Some suppliers offer paid samples refundable against future orders. Free samples are rare but possible for high-potential buyers. Budget $0.05–$15 per unit depending on type and complexity.

How to initiate customization requests?

Submit detailed specifications including resistance value, power rating, taper curve, shaft dimensions, terminal type, and environmental requirements (IP rating, operating temperature). Reputable suppliers respond with technical feasibility assessments and CAD drawings within 48–72 hours.