Vendor Form Example

About vendor form example

Where to Find Vendor Form Example Suppliers?

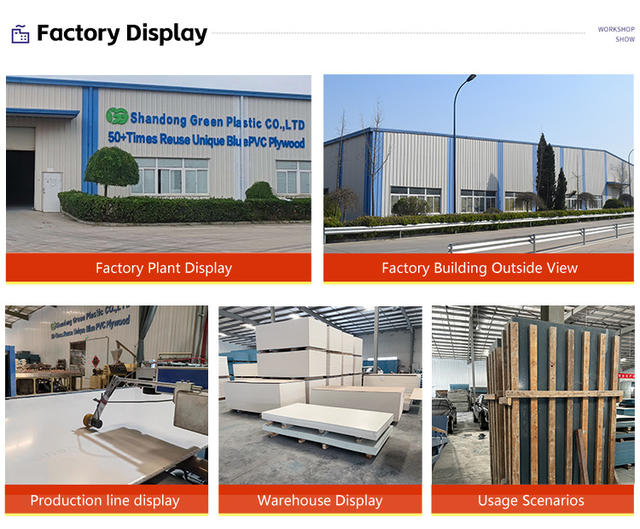

China remains the dominant source for prefabricated formwork systems, with key manufacturing clusters in Tianjin, Hubei, and Shandong provinces. These regions host vertically integrated production facilities specializing in steel, aluminum, and plastic-based formwork solutions. Tianjin and Qingdao serve as major export hubs due to proximity to deep-water ports, enabling efficient containerized shipping. Hubei has emerged as a center for aluminum formwork innovation, supported by localized extrusion and anodizing infrastructure that reduces material lead times by 10–15 days compared to offshore alternatives.

Suppliers in these industrial zones benefit from consolidated supply chains for raw materials—such as galvanized steel coils, 6061-T6 aluminum alloys, and high-impact polypropylene—allowing cost advantages of 20–35% over Western manufacturers. The concentration of component fabricators, CNC processing centers, and logistics providers within 50km radii enables rapid prototyping and scalable production. Standard order fulfillment typically ranges from 25 to 40 days, with customization options available across material grade, panel dimensions, and surface treatments.

How to Choose Vendor Form Example Suppliers?

Evaluate suppliers using the following criteria to ensure quality, compliance, and operational reliability:

Material & Technical Specifications

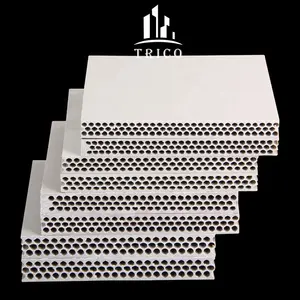

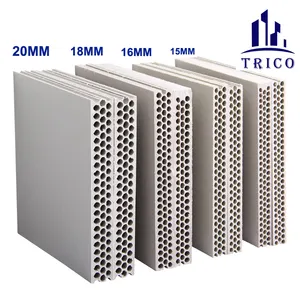

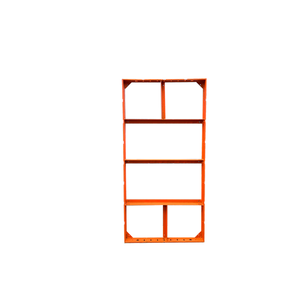

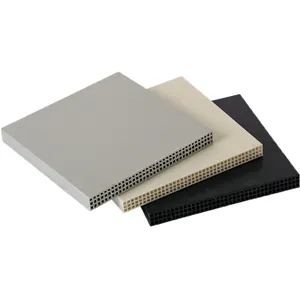

Confirm the base material type (steel, aluminum, or plastic) aligns with project durability and reuse requirements. Aluminum systems (e.g., 6061-T6) offer lightweight handling and 300+ reuse cycles, while galvanized steel forms provide higher load-bearing capacity for heavy-duty pours. Plastic forms are cost-effective for low-rise projects but may degrade after 50–80 uses under UV exposure.

Production Capacity Verification

Assess infrastructure indicators:

- Minimum factory area exceeding 3,000m² for consistent output

- In-house CNC cutting, welding, and surface treatment lines

- Monthly production capacity above 10,000 square meters for bulk orders

Cross-reference online revenue metrics and reorder rates as proxies for market validation and customer retention.

Quality Assurance & Transaction Security

While formal ISO 9001 certification is not universally declared in available data, prioritize suppliers reporting 100% on-time delivery and response times under 2 hours as indirect indicators of operational discipline. Request test reports for weld integrity, deflection tolerance (< 1/500 span), and corrosion resistance (salt spray testing for coated metals). Utilize secure payment mechanisms and require sample validation before full-scale ordering.

What Are the Best Vendor Form Example Suppliers?

| Company Name | Main Material | Form Type | Min. Order Quantity | Avg. Price Range | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Tianjin Taishouxing International Co., Ltd. | Steel | Modular, Reusable, Heavy-Duty | 200 sqm / 200 pcs | $15–59.99 | 100.0% | ≤1h | 33% | $2.8M+ |

| Hubei ADTO Aluminum Formwork Manufacturing Co., Ltd. | Aluminum (6061-T6) | Wall, Slab, Column Systems | 50–100 sqm | $100–136 | 100.0% | ≤3h | <15% | $410K+ |

| MTM BUILDING MATERIALS CO.,LTD | Plastic | Insulating, Reusable, High-Strength | 3–100 pcs | $9–23.20 | 100.0% | ≤3h | 44% | $1.5M+ |

| Qingdao Qinyuan Steel Co., Ltd. | Steel, Timber | Painted Steel, Timber Frame | 100 pcs | $8–55 | 100.0% | ≤2h | <15% | $1.3M+ |

| Linyi Formwork New Material Co., Ltd. | Steel, Plywood | Euro-Style, Frame, Filler | 100 sqm / 100 pcs | $10–120 | 100.0% | ≤5h | - | - |

Performance Analysis

Tianjin Taishouxing stands out with the highest reported online revenue ($2.8M+) and fastest response time (≤1h), indicating strong operational efficiency and buyer engagement. Despite higher per-unit pricing, Hubei ADTO specializes in precision aluminum systems suited for high-rise construction, though its lower reorder rate suggests potential gaps in post-sale support. MTM Building Materials demonstrates strong market retention (44% reorder rate) with competitively priced plastic forms and extensive customization capabilities, including color, logo, and packaging options. Qingdao Qinyuan offers the widest material range, including timber alternatives, at entry-level price points. Linyi Formwork, while lacking financial disclosures, maintains a focused product line with Euro-standard compatibility, appealing to international contractors.

FAQs

What are typical MOQs for vendor form examples?

Minimum order quantities vary by material: steel and aluminum forms typically require 100–200 square meters, while plastic panels can be sourced in batches as small as 3–100 pieces. Some suppliers allow mixed-container orders to accommodate smaller buyers.

How long does production and shipping take?

Manufacturing lead time averages 25–40 days post-design approval. Sea freight to North America or Europe adds 25–35 days. Air shipping is not viable for bulk orders due to size and weight constraints.

Can I customize form dimensions and finishes?

Yes, most suppliers support dimensional adjustments, surface coatings (galvanized, painted, anodized), and branding (laser logos, labels). MTM Building Materials explicitly lists customization for color, size, and packaging, making it ideal for private-label procurement.

Are samples available before bulk ordering?

Sample availability depends on supplier policy. Smaller components (e.g., plastic form panels) may be provided at nominal cost, while full-scale steel or aluminum forms incur higher sampling fees. Expect 7–14 days for sample production and 5–10 days for express delivery.

What quality checks should be performed upon receipt?

Inspect for dimensional accuracy (±1mm tolerance), weld consistency, edge straightness, and surface defects. Conduct a dry assembly test to verify interlocking mechanism functionality. For aluminum forms, verify alloy grade via mill test reports. Retain samples for field performance benchmarking over multiple pour cycles.