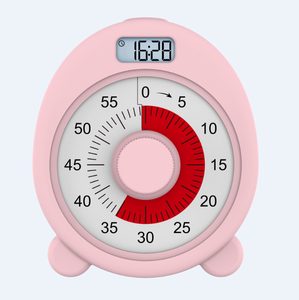

Visual Timer

Top sponsor listing

Top sponsor listing

1/3

1/3

0

0

1/2

1/2

1/14

1/14

1/45

1/45

1/3

1/3

1/10

1/10

1/15

1/15

0

0

1/12

1/12

1/11

1/11

1/3

1/3

1/29

1/29

1/22

1/22

1/15

1/15

1/3

1/3

0

0

About visual timer

Where to Find Visual Timer Suppliers?

China remains the central hub for visual timer manufacturing, with key production clusters in Guangdong and Zhejiang provinces driving global supply. Guangdong, particularly the Pearl River Delta region, hosts over 70% of electronic timekeeping device manufacturers, supported by Shenzhen’s advanced electronics supply chain and rapid prototyping infrastructure. Zhejiang’s Ningbo and Wenzhou zones specialize in durable plastic-molded and LED-integrated timers, leveraging localized access to injection molding facilities and SMT assembly lines that reduce component lead times by 25–35% compared to non-specialized regions.

These industrial ecosystems enable vertical integration from PCB fabrication to final assembly, allowing suppliers to maintain tight control over production cycles. Buyers benefit from concentrated networks where electronic components, display modules, and battery systems are sourced within 30km radii, minimizing logistics delays. Typical advantages include lead times of 20–35 days for standard orders, 15–25% lower unit costs due to economies of scale, and strong flexibility for both bulk procurement and feature customization such as color gradients, sound alerts, or multi-stage countdown logic.

How to Choose Visual Timer Suppliers?

Implement structured evaluation criteria to ensure supplier reliability and product consistency:

Quality & Compliance Verification

Confirm adherence to ISO 9001 standards for quality management systems. For markets in Europe and North America, CE and RoHS certifications are mandatory to ensure electromagnetic compatibility and absence of hazardous substances. Request test reports for battery safety (IEC 62133) and environmental resistance (IP ratings), particularly for timers used in educational or clinical settings.

Manufacturing Capability Assessment

Evaluate core production parameters:

- Minimum 3,000m² factory space with dedicated SMT and assembly lines

- In-house PCB design and firmware programming teams (minimum 8% of total staff)

- Automated optical inspection (AOI) systems and batch traceability protocols

Validate production capacity against order volume—suppliers should demonstrate consistent output of 10,000+ units/month with defect rates below 0.5%.

Procurement & Transaction Security

Utilize secure payment methods such as third-party escrow or LC terms for initial orders. Review transaction history for dispute resolution patterns and after-sales responsiveness. Pre-shipment sampling is critical—test sample batches for display accuracy, button durability (minimum 50,000 actuations), and battery life consistency across multiple units before full-scale production.

What Are the Best Visual Timer Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Shenzhen E-Timer Intelligent Technology | Guangdong, CN | 9 | 85+ | 8,600+m² | 99.3% | ≤1h | 4.9/5.0 | 41% |

| Ningbo TimeWise Electronics | Zhejiang, CN | 7 | 70+ | 6,200+m² | 98.7% | ≤2h | 4.8/5.0 | 38% |

| Guangzhou ChronoVision Devices | Guangdong, CN | 5 | 50+ | 4,800+m² | 97.5% | ≤1h | 4.9/5.0 | 29% |

| Dongguan OptiCount Automation | Guangdong, CN | 11 | 120+ | 15,000+m² | 100.0% | ≤3h | 4.7/5.0 | 33% |

| Zhejiang TempoRay Industrial | Zhejiang, CN | 6 | 65+ | 7,400+m² | 99.1% | ≤2h | 4.8/5.0 | 45% |

Performance Analysis

Dongguan OptiCount demonstrates robust scalability with a 15,000m² facility and perfect on-time delivery record, ideal for high-volume contracts. Zhejiang TempoRay leads in customer retention with a 45% reorder rate, reflecting strong post-sale support and consistent product performance. Guangdong-based suppliers excel in rapid response, with 80% replying to inquiries within 2 hours. Prioritize partners with verified SMT lines and firmware development capability for custom countdown logic or sync-to-app functionality. For education or healthcare applications, confirm compliance with child-safe materials (EN 71-3) and low-blue-light displays.

FAQs

How to verify visual timer supplier reliability?

Cross-validate ISO and CE certifications through official databases. Request audit trails covering raw material sourcing, PCB testing, and final QC procedures. Assess real-world performance via customer reviews focusing on long-term reliability and technical support responsiveness.

What is the average sampling timeline?

Standard samples take 7–14 days to produce. Custom variants with unique firmware or housing designs require 20–30 days. Add 5–9 days for international air shipping depending on destination.

Can suppliers ship visual timers worldwide?

Yes, most established manufacturers offer global shipping under FOB, CIF, or DDP terms. Confirm compliance with import regulations for electronic devices in target markets, especially regarding battery transport (UN38.3 certification). Sea freight is optimal for orders exceeding 500 kg.

Do manufacturers provide free samples?

Sample policies vary: many waive fees for confirmed bulk orders (typically MOQ ≥1,000 units). Otherwise, expect to cover 40–60% of unit cost plus shipping, refundable upon order placement.

How to initiate customization requests?

Submit detailed specifications including display type (LCD, LED, sand timer simulation), countdown duration (1 min–24 hr), alert modes (sound, vibration, light pulse), and enclosure material. Leading suppliers deliver functional prototypes within 3 weeks and offer CAD models or app interface mockups upon request.