What Is Automation In Production

Top sponsor listing

Top sponsor listing

1/7

1/7

1/4

1/4

1/25

1/25

About what is automation in production

What Is Automation in Production?

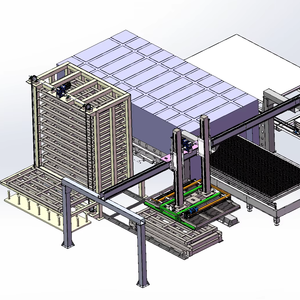

Automation in production refers to the integration of control systems, machinery, and software to perform manufacturing tasks with minimal human intervention. This includes technologies such as programmable logic controllers (PLCs), robotic arms, conveyor systems, machine vision inspection, and automated storage solutions. The primary objectives are to enhance operational efficiency, improve product consistency, reduce labor costs, and enable scalable output across industries ranging from automotive to electronics and logistics.

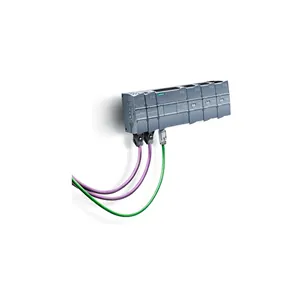

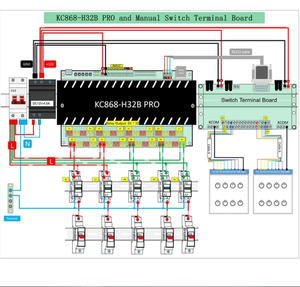

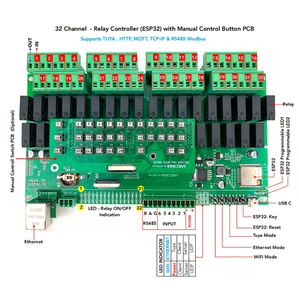

Industrial automation leverages real-time data monitoring, feedback loops, and process optimization algorithms to synchronize assembly lines, material handling, and quality assurance protocols. Key components include sensors, actuators, human-machine interfaces (HMIs), and industrial PCs that communicate via standardized networks like PROFINET or Modbus. As global demand for smart manufacturing grows, automation systems are increasingly incorporating AI-driven vision systems and IoT-enabled predictive maintenance to support Industry 4.0 initiatives.

Where Are Automation Systems Manufactured?

China remains a dominant hub for automation system manufacturing, with concentrated supplier clusters in Fujian, Shanghai, Guangdong, and Shandong provinces. These regions host vertically integrated ecosystems where component fabrication, system integration, and final testing occur within proximity, reducing lead times and logistics overhead. Quanzhou and Huizhou, for example, specialize in electromechanical drive systems and linear guide conveyors, while Shanghai excels in high-precision PLCs and industrial controllers.

Suppliers in these zones benefit from localized access to steel, aluminum, PCBs, motors, and electronic controls, enabling rapid prototyping and cost-effective scaling. Facilities typically range from 5,000m² to over 24,000m², supporting batch production and custom engineering projects. Export-ready infrastructure ensures compliance with international shipping standards, with many suppliers experienced in delivering turnkey automation lines to North America, Europe, and Southeast Asia.

How to Choose Automation System Suppliers?

Selecting reliable partners requires structured evaluation across technical, operational, and transactional dimensions:

Technical Capability Verification

Confirm expertise in core automation domains: programmable controllers, motion control, robotic integration, or vision-based inspection. Prioritize suppliers offering documented design schematics, system validation reports, and compatibility with industrial communication protocols (e.g., PROFINET, EtherCAT). For safety-critical applications, CE marking and adherence to IEC 61131-3 for PLC programming are essential.

Production Infrastructure Assessment

Evaluate key indicators of manufacturing maturity:

- Facility size exceeding 3,000m² to support full-line assembly

- In-house engineering teams capable of customization (e.g., adjustable speed drives, solar-powered gate operators)

- Integrated processing capabilities including CNC machining, sheet metal forming, and control board assembly

Cross-reference on-time delivery rates (target ≥98%) and response times (ideally ≤2 hours) as proxies for operational reliability.

Quality & Transaction Assurance

Require evidence of systematic quality management—preferably ISO 9001 certification. Utilize secure payment mechanisms tied to milestone verification, especially for capital-intensive systems priced above $15,000. Conduct pre-shipment inspections or request factory audit videos to validate production conditions. For complex integrations, insist on pilot testing or simulation models before full deployment.

What Are the Leading Automation System Suppliers?

| Company Name | Location | Supplier Type | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate |

|---|---|---|---|---|---|---|---|

| Quanzhou Autoga Machinery Co., Ltd. | Fujian, CN | Custom Manufacturer | Automatic Door Operators, Gate Operators, Control Boards, Solar-Powered Systems | US $90,000+ | 98% | ≤7h | 27% |

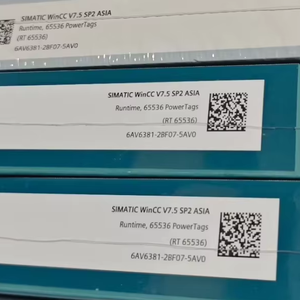

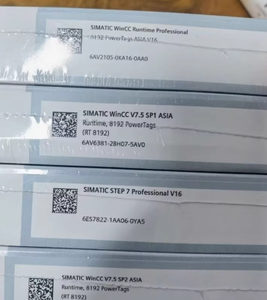

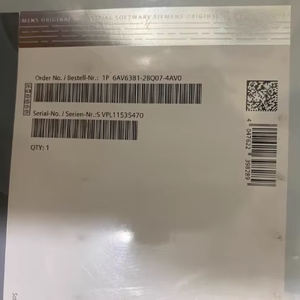

| Shanghai Pouwell Technology Co., Ltd. | Shanghai, CN | Trading & Manufacturing | PLCs, PROFINET Switches, Industrial Controllers, Relays | US $60,000+ | 100% | ≤1h | 57% |

| SENSOVISION SYSTEMS PRIVATE LIMITED | India | Specialized Manufacturer | Machine Vision Inspection Systems, AI Optical Sorting, AOI Equipment | Not Disclosed | Not Available | ≤9h | Not Available |

| Huizhou Zhenji Automation Technology Co., Ltd. | Guangdong, CN | Custom Manufacturer | Conveyor Systems, Linear Guides, Assembly Lines, Precision Guide Rails | US $10,000+ | 100% | ≤1h | 50% |

| Jinan Chuangyi Intelligent Equipment Co., Ltd. | Shandong, CN | Integrated Solutions Provider | Automated Storage Warehouses, Sheet Metal Processing Lines, Articulated Robots | US $2,000+ | 100% | ≤2h | <15% |

Performance Analysis

Shanghai Pouwell and Huizhou Zhenji demonstrate strong responsiveness (≤1h average reply time) and perfect on-time delivery records, indicating robust internal coordination. Shanghai Pouwell’s 57% reorder rate reflects high customer retention in the industrial control segment, while Quanzhou Autoga offers broad customization in motorized door and gate systems. SENSOVISION specializes in high-value AI-driven optical inspection systems priced at $15,000+ per unit, targeting quality-critical sectors like automotive and electronics. Jinan Chuangyi provides large-scale automated warehousing solutions but shows a lower reorder rate, suggesting niche market positioning or longer procurement cycles.

FAQs

What certifications should automation system suppliers have?

At minimum, ISO 9001 for quality management is expected. For export to regulated markets, CE certification (EU), UL listing (North America), or RoHS compliance for hazardous substances may be required, particularly for electrical and control components.

What is the typical MOQ and lead time?

Minimum order quantities are often set at 1 unit for fully assembled systems. Lead times vary by complexity: standard PLCs or relays ship within 7–15 days, while custom conveyor or warehouse systems require 30–60 days for fabrication and testing.

Can automation systems be customized?

Yes, most suppliers offer configuration options such as variable speed controls, waterproof enclosures, solar operation, smartphone connectivity, and integration with existing SCADA systems. Custom mechanical dimensions (e.g., rack length, load capacity) are commonly supported upon technical review.

How are high-value automation systems shipped internationally?

Suppliers typically offer FOB or CIF shipping terms. Large systems are crated and containerized for sea freight, while smaller controllers may be air-shipped. Buyers should confirm packaging standards, insurance coverage, and import compliance documentation prior to shipment.

Do suppliers provide technical support after delivery?

Support levels vary. Leading suppliers offer wiring diagrams, user manuals, remote troubleshooting, and in some cases, on-site commissioning. Verify post-sale service scope—including warranty duration (typically 12 months)—before procurement.