What Is Container In Docker

0

0

CN

CN

1/10

1/10

1/3

1/3

CN

CN

CN

CN

1/1

1/1

1/3

1/3

1/3

1/3

CN

CN

1/25

1/25

1/1

1/1

1/20

1/20

1/3

1/3

1/12

1/12

1/3

1/3

1/1

1/1

1/15

1/15

0

0

1/3

1/3

1/3

1/3

1/18

1/18

About what is container in docker

Where to Find Container in Docker Suppliers?

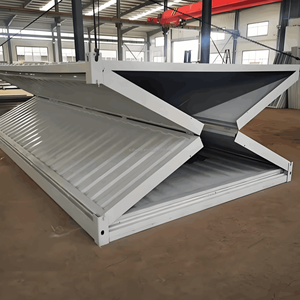

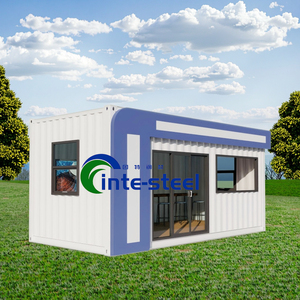

The term "container in Docker" commonly refers to software containers used in DevOps and cloud computing environments. However, supplier platforms interpret the keyword literally, listing physical container structures such as modular houses, portable kiosks, and prefabricated units that resemble shipping container-based constructions. These products are primarily manufactured in China, with key production clusters in Guangdong, Shandong, and Liaoning provinces. These regions host vertically integrated steel and prefab construction ecosystems, enabling rapid fabrication of containerized buildings using standardized ISO freight container dimensions.

Suppliers leverage automated cutting, welding, and assembly lines to produce modular units with lead times ranging from 15 to 30 days for standard configurations. The industrial base benefits from proximity to raw material sources—particularly cold-rolled steel and insulation composites—reducing input costs by 15–25% compared to Western fabricators. Buyers gain access to scalable production networks capable of fulfilling both single-unit pilot orders and bulk deployments exceeding 100 units. Common applications include mobile offices, pop-up retail stores, container cafes, and temporary housing solutions.

How to Choose Container in Docker Suppliers?

Selecting reliable suppliers requires rigorous evaluation across technical, operational, and transactional criteria:

Technical Specifications & Compliance

Verify structural compliance with international standards such as ISO 1496 for cargo container modifications and CE marking for construction products where applicable. Ensure fire resistance ratings (e.g., A-class non-combustible materials), wind load tolerance (≥120 km/h), and thermal insulation performance (U-value ≤0.35 W/m²K) are documented. For electrical installations in kitchen or office units, confirm adherence to IEC 60364 standards.

Production Capability Assessment

Evaluate core manufacturing indicators:

- Minimum factory area of 5,000m² to support batch production

- In-house capabilities in CNC cutting, MIG/TIG welding, and powder coating

- Dedicated R&D or design teams offering layout customization

Cross-reference listed product ranges with on-time delivery records (target ≥97%) and response times (ideally ≤5 hours).

Customization and Transaction Security

Prioritize suppliers advertising customization options for color, size, interior layout, and branding elements. Confirm packaging specifications (flat-pack vs. fully assembled) and export readiness. Utilize secure payment mechanisms such as escrow services or letters of credit. Request prototypes or site visits before large-scale orders. Validate after-sales support, including installation guidance and warranty terms (typically 1–2 years).

What Are the Best Container in Docker Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Guangzhou Perfect Dream Modular House Co., Ltd. | Guangdong, CN | Data not available | Data not available | Data not available | 100% | ≤5h | N/A | Not specified |

| Beike Steel Structure (Shandong) Co., Ltd. | Shandong, CN | Data not available | Data not available | Data not available | 100% | ≤3h | N/A | Not specified |

| Dalian Exxon Trading Co.,Ltd | Liaoning, CN | Data not available | Data not available | Data not available | 100% | ≤3h | N/A | <15% |

| usgowin LLC | Data not available | Data not available | Data not available | Data not available | Not specified | ≤2h | N/A | Not specified |

| DAZGLOR CREATIONS | Data not available | Data not available | Data not available | Data not available | Not specified | ≤4h | N/A | Not specified |

Performance Analysis

Guangzhou Perfect Dream and Beike Steel Structure demonstrate strong operational reliability with 100% on-time delivery and sub-5-hour average response times. Both companies offer extensive customization, particularly in layout and finish options, making them suitable for branded commercial deployments. Dalian Exxon stands out for price competitiveness, offering units starting below $1,000 per set, though its low reorder rate suggests limited customer retention. usgowin LLC provides mid-range pricing and fast responsiveness but lacks verified delivery metrics. DAZGLOR CREATIONS appears misaligned with structural container demand, listing small wooden storage boxes at $2–6 per piece, indicating keyword mismatch rather than relevant product expertise.

FAQs

How to verify container in Docker supplier reliability?

Cross-check company registration details and request evidence of past projects or client references. Demand third-party inspection reports (e.g., SGS or Bureau Veritas) covering structural integrity, material sourcing, and quality control processes. Analyze buyer feedback focusing on build quality, delivery accuracy, and post-purchase communication.

What is the average sampling timeline?

Standard sample production takes 10–20 days depending on complexity. Fully customized units with integrated utilities (plumbing, HVAC, electrical) may require 25–35 days. Air freight delivery adds 5–10 days internationally. Some suppliers offer digital 3D models within 72 hours for preliminary approval.

Can suppliers ship container units worldwide?

Yes, most established manufacturers manage global logistics via FOB, CIF, or DDP terms. Units are typically shipped by sea freight in 20ft or 40ft configurations. Confirm compliance with destination country building codes and customs classifications for prefabricated structures. Ro-Ro or containerized shipping methods are standard.

Do manufacturers provide free samples?

Full-unit samples are rarely offered free due to high production and shipping costs. Some suppliers waive sample fees for confirmed bulk orders (e.g., 10+ units). Digital renderings and virtual tours are often provided at no cost to evaluate design feasibility.

How to initiate customization requests?

Submit detailed requirements including exterior dimensions, door/window placement, insulation type, utility connections (water, electricity, sewage), and interior finishes. Reputable suppliers respond with CAD drawings or 3D visualizations within 3–5 business days and can adjust prototypes based on feedback prior to mass production.