What Is Die Casting Used To Make

Top sponsor listing

Top sponsor listing

About what is die casting used to make

What Is Die Casting Used to Make?

Die casting is a high-precision manufacturing process widely used to produce complex, dimensionally stable metal components under high pressure. It is primarily employed in industries requiring lightweight, durable parts with tight tolerances—such as automotive, aerospace, consumer electronics, and industrial machinery. Common applications include engine blocks, transmission housings, structural brackets, connector housings, heat sinks, and precision enclosures for power tools and lighting systems.

The process supports both aluminum and zinc alloys, with aluminum-based die casting dominating due to its favorable strength-to-weight ratio and corrosion resistance. Components produced via die casting offer superior surface finish and minimal need for secondary machining, reducing overall production costs. The scalability of the process allows for high-volume output—ideal for OEMs and contract manufacturers seeking consistent part quality across large batches.

Where Are Die Casting Machine Suppliers Located?

China remains the global epicenter for die casting machine manufacturing, with key supplier clusters concentrated in Zhejiang, Guangdong, and Anhui provinces. These regions host vertically integrated ecosystems that combine foundry operations, CNC machining centers, mold design studios, and assembly facilities within close proximity, enabling rapid prototyping and streamlined production cycles.

Zhejiang’s Taizhou region specializes in cold-chamber die casting machines optimized for aluminum alloy processing, while Jiangmen in Guangdong has emerged as a hub for turnkey machinery solutions, including full-line automation integration. Anhui’s Bengbu area focuses on high-tonnage models (500T–1000T), catering to automotive component producers. Proximity to raw material suppliers and port infrastructure reduces logistics lead times by 20–30% compared to offshore alternatives, particularly for buyers sourcing from Ningbo, Shenzhen, or Shanghai ports.

How to Choose Die Casting Machine Suppliers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional parameters:

Technical Capability Verification

Confirm suppliers offer machines compatible with required alloy types (e.g., cold-chamber for aluminum, hot-chamber for zinc). Evaluate available tonnage range—common models span 80T to 1000T—with higher capacity suited for large automotive or industrial parts. Request detailed specifications covering injection speed, plunger diameter, mold thickness, and energy consumption metrics.

Production Infrastructure Assessment

Prioritize suppliers with verified in-house engineering teams and R&D capabilities. Key indicators include:

- Minimum factory area exceeding 3,000m² for scalable production

- In-house mold design and testing facilities

- Demonstrated customization options: cycle time adjustment, material compatibility, color coding, labeling, packaging, and 3D drawing support

Cross-reference declared response times (ideally ≤2 hours) and on-time delivery performance (>97%) to assess operational reliability.

Quality & Transaction Assurance

While formal certifications like ISO 9001 are not explicitly listed in available data, prioritize suppliers demonstrating consistent reorder rates (≥50%) and short response windows (≤1h). Utilize third-party inspection services to validate machine condition, especially when purchasing used equipment. Escrow payment mechanisms should be employed until post-delivery verification is completed. For new machines, request test reports on hydraulic system stability, clamping force accuracy, and PLC control responsiveness.

What Are the Top Die Casting Machine Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|

| Jiangmen Zhenli Machinery Co., Ltd. | Guangdong, CN | Die Casting Machine, Metal Casting Machinery, Injection Molding Machines | US $70,000+ | 100% | ≤2h | <15% | Yes (cycle time, material, size, logo, packaging, 3D drawings) |

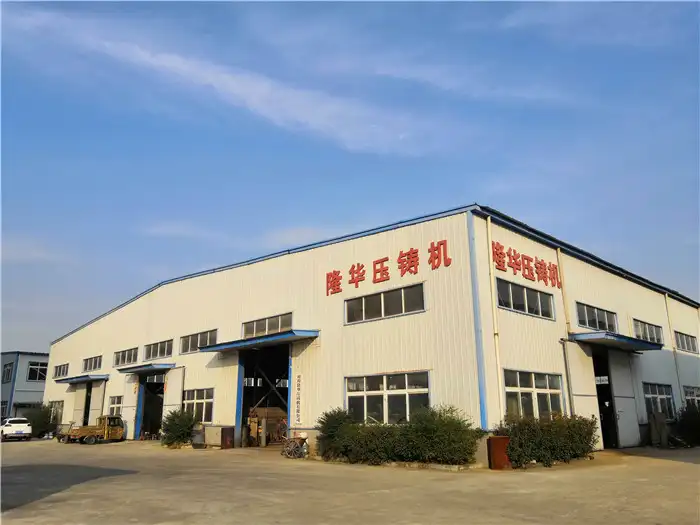

| Bengbu Longhua Die Casting Machine Co., Ltd. | Anhui, CN | Die Casting Machine (HPDC, HDC series) | US $880,000+ | 100% | ≤1h | 100% | Yes (color, size, logo, packaging, label) |

| Taizhou Jiuguan Machinery Technology Co., Ltd. | Zhejiang, CN | Die Casting Machine (Aluminum, Cold-Chamber) | Not specified | 100% | ≤1h | - | No explicit mention |

| Gz Risun Machine Company Limited | Guangdong, CN | Used Die Casting Machines, Injection Molding Machines | US $140,000+ | 100% | ≤9h | 50% | No explicit mention |

| Longnan City Brotherholding Protective Equipment Co., Ltd. | Jiangxi, CN | Used Die Casting Machines (LK, Haitian models) | US $5,000+ | 100% | ≤4h | 100% | No explicit mention |

Performance Analysis

Bengbu Longhua stands out with the highest online revenue (US $880,000+) and a 100% reorder rate, indicating strong customer satisfaction and repeat business—likely driven by responsive service (≤1h) and customization flexibility. Jiangmen Zhenli offers broad product diversification and solid throughput capacity, though its low reorder rate (<15%) suggests limited post-sale engagement or niche market positioning. Taizhou Jiuguan demonstrates fast responsiveness and full delivery compliance but lacks transparency on sales volume and customization scope.

Suppliers offering used machines—Gz Risun and Longnan City Brotherholding—cater to cost-sensitive buyers seeking entry-level or replacement units. Gz Risun’s 50% reorder rate reflects moderate buyer retention, while Longnan maintains perfect delivery records despite lower revenue, suggesting focused, small-batch operations. However, both report longer response times than leaders, which may impact service agility.

FAQs

What materials are compatible with die casting machines?

Most industrial die casting machines handle aluminum, zinc, and magnesium alloys. Cold-chamber machines are standard for high-melting-point metals like aluminum, while hot-chamber systems are optimized for zinc and low-pressure applications.

What is the typical MOQ and lead time?

Minimum order quantity is typically 1 set, especially for machinery. Lead time ranges from 15–30 days for standard configurations; customized or high-tonnage models may require 45–60 days depending on complexity and supplier workload.

Can suppliers provide custom die casting solutions?

Yes, leading suppliers such as Jiangmen Zhenli and Bengbu Longhua offer extensive customization—including machine type, mold weight, cycle parameters, and branding elements. Technical documentation, including 3D drawings and control schematics, is typically provided upon request.

Are used die casting machines reliable for production use?

Used machines from reputable brands (e.g., LK, TOYO, Haitian) can be viable if properly refurbished. Buyers should request maintenance logs, perform pre-shipment inspections, and verify functional testing results before acceptance.

How do I verify supplier credibility?

Evaluate on-time delivery history, response consistency, and transaction volume. Request facility videos or virtual audits to confirm production capabilities. Use secure payment methods with milestone-based releases tied to inspection outcomes.