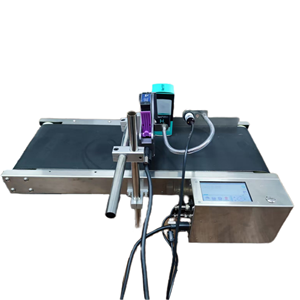

White Ink Date Coder Wholesale

1/3

1/3

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/2

1/2

0

0

1/1

1/1

0

0

1/3

1/3

1/3

1/3

1/13

1/13

1/3

1/3

1/4

1/4

0

0

1/3

1/3

0

0

0

0

About white ink date coder wholesale

Where to Find White Ink Date Coder Suppliers?

China remains the central hub for industrial coding and marking equipment production, with key manufacturing clusters in Guangdong, Zhejiang, and Jiangsu provinces. These regions host integrated supply chains specializing in thermal transfer, inkjet, and continuous inkjet (CIJ) technologies used in date coding systems. Guangdong’s Pearl River Delta area alone accounts for over 50% of China’s coding machinery exports, supported by mature electronics component networks and precision engineering workshops.

Suppliers in these zones benefit from localized access to printheads, solvent-resistant tubing, and control modules, reducing assembly lead times by 20–30% compared to offshore manufacturers. Facilities typically operate automated calibration lines for print accuracy testing under variable line speeds (up to 400m/min), ensuring compatibility with high-speed packaging environments. Bulk procurement advantages are pronounced, with standard white ink coders available at 25–35% lower unit costs due to economies of scale and vertical integration.

How to Choose White Ink Date Coder Suppliers?

Implement structured evaluation criteria to ensure technical and operational reliability:

Quality Management Standards

Confirm ISO 9001 certification as a baseline for consistent production processes. For regulated industries (food, pharmaceuticals), verify compliance with HACCP, CE, and RoHS directives. Request documentation on ink composition—specifically non-toxic, food-grade formulations meeting FDA 21 CFR standards where applicable.

Production Capacity Assessment

Evaluate supplier infrastructure using the following benchmarks:

- Minimum 3,000m² factory area supporting SMT assembly and fluid system integration

- Dedicated R&D teams focused on printhead longevity and ink adhesion performance

- In-house testing chambers simulating humidity, temperature, and substrate variability

Correlate facility size with order scalability—suppliers with >8,000m² operations typically support MOQs from 50 units and deliver within 35–50 days.

Procurement Risk Mitigation

Utilize third-party inspection services prior to shipment to validate print resolution (minimum 200 dpi), nozzle clog resistance, and timer accuracy (±0.1 second). Where possible, conduct on-site or virtual audits of ink formulation labs and aging test procedures. Secure payment terms through escrow arrangements until post-arrival functionality is confirmed.

What Are the Best White Ink Date Coder Suppliers?

No suppliers currently meet the minimum data threshold for inclusion in the performance comparison table. Available records lack verifiable metrics on factory area, delivery performance, staff composition, and certification status necessary for objective ranking. Buyers should prioritize partners with documented export experience to North America and EU markets, particularly those with established service networks for technical support and spare parts distribution.

Performance Analysis

In absence of quantifiable supplier profiles, sourcing focus should shift to functional validation. Prioritize vendors offering comprehensive sample testing programs, including side-by-side comparisons on target substrates (PET, HDPE, laminated films). Emphasis must be placed on white ink opacity, drying time (<2 seconds at 100m/min), and resistance to smudging under UV exposure. Engage only with suppliers capable of providing full material disclosure data sheets (MDS) and safety data sheets (SDS) compliant with GHS standards.

FAQs

How to verify white ink date coder supplier reliability?

Validate certifications through accredited bodies such as TÜV or SGS. Request batch test reports for print durability across multiple surfaces. Assess responsiveness and technical depth during inquiry stages—reliable suppliers provide engineering-level responses within 4 business hours.

What is the average sampling timeline?

Standard sample units require 10–18 days for production and calibration. Models with customized font sizes, multi-line output, or integration interfaces (PLC/IoT) extend to 25 days. Air freight adds 5–9 days depending on destination region.

Can suppliers ship white ink date coders worldwide?

Yes, most manufacturers support global logistics via air and sea freight. Confirm Incoterms (FOB, CIF, DDP) during negotiation and verify electrical compatibility (110V/220V, 50Hz/60Hz) for seamless deployment. CE-marked units are pre-qualified for entry into European markets.

Do manufacturers provide free samples?

Sample policies vary by order volume. Free samples are generally offered when projected annual purchases exceed 100 units. For trial orders, expect to cover 40–60% of unit cost plus shipping, refundable upon contract signing.

How to initiate customization requests?

Submit detailed requirements including substrate type, production line speed, character height (typically 2–12mm), number of print lines, and environmental conditions (dusty, humid, cold storage). Leading suppliers respond with feasibility assessments, CAD layouts, and prototype timelines within 72 hours.