Wholesale Automated Sorting Systems

0

0

1/3

1/3

1/31

1/31

1/3

1/3

0

0

CN

CN

1/2

1/2

0

0

1/1

1/1

CN

CN

1/3

1/3

0

0

1/3

1/3

1/3

1/3

0

0

1/11

1/11

0

0

1/3

1/3

1/12

1/12

About wholesale automated sorting systems

Where to Find Wholesale Automated Sorting Systems Suppliers?

China remains the global hub for automated sorting systems manufacturing, with key production clusters in Guangdong, Anhui, and Jiangsu provinces. Dongguan and Shenzhen in Guangdong specialize in conveyor-based intelligent sorting solutions for logistics and warehouse automation, leveraging proximity to electronics component suppliers for rapid integration of sensors, AI-driven vision systems, and control modules. Hefei in Anhui has emerged as a center for optical and color sorting technology, particularly for agricultural and food processing applications, supported by regional expertise in optoelectronics and machine learning algorithms.

These industrial ecosystems enable vertically integrated production, where suppliers manage everything from structural fabrication to software calibration in-house. This integration reduces component lead times and supports customization at scale. Buyers benefit from competitive pricing due to localized supply chains—particularly in sensor arrays and servo mechanisms—and access to modular designs that can be adapted across industries including agriculture, recycling, e-commerce logistics, and mining. Typical lead times range from 20–45 days depending on system complexity, with bulk orders often fulfilled within six weeks.

How to Choose Wholesale Automated Sorting Systems Suppliers?

Selecting reliable suppliers requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Capabilities & Compliance

Verify that suppliers offer systems compliant with international safety and performance standards such as CE or ISO 9001. For optical sorters using CCD or AI-based detection, confirm validation reports for accuracy rates (typically >98% for high-end models). In food-grade applications, ensure materials meet FDA or equivalent hygiene requirements. Demand detailed specifications on camera resolution, belt speed, rejection mechanisms, and compatibility with existing production lines.

Production Infrastructure Assessment

Evaluate supplier capacity based on physical and engineering resources:

- Minimum factory area of 3,000m² to support assembly of large-scale sorting lines

- In-house R&D teams focused on software development and mechanical design

- Integrated testing facilities for dry-run validation before shipment

Cross-reference online revenue metrics and reorder rates: suppliers with reorder rates above 20% indicate customer satisfaction and product reliability.

Customization and After-Sales Support

Confirm capability for tailored configurations—including size, throughput capacity, material compatibility, and branding options. Prioritize suppliers offering remote diagnostics, multilingual technical documentation, and on-site installation guidance. Response time under 4 hours is indicative of strong customer service infrastructure.

What Are the Best Wholesale Automated Sorting Systems Suppliers?

| Company Name | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|---|

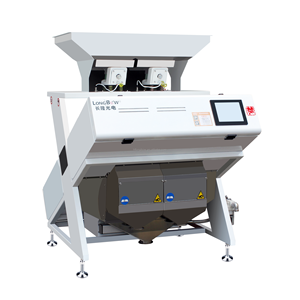

| Hefei Longbow Optoelectronic Technology Co., Ltd. | Color Sorter, Optical Sorting Machines | $5,500–$9,200 | 1 set | 33% | ≤6h | 66% | US $170,000+ | Material-specific tuning, AI integration |

| Dongguan Mingwei Conveyor Technology Co., Ltd. | DWS Systems, Cross-Belt Conveyors | $7,999–$12,999 | 1 set | 100% | ≤4h | 20% | US $720,000+ | Full system customization, logo, size, color |

| Tonten Machinery Limited | Waste Sorting Plants, Recycling Equipment | $60,000–$90,000 | 5 sets | 100% | ≤3h | <15% | US $100,000+ | Limited customization, standard plant models |

| Lerford Machine LLC | Fruit & Vegetable Sorters, Color Graders | $1,079–$5,499 | 1 unit | - | ≤2h | - | - | Basic model variations |

Performance Analysis

Dongguan Mingwei stands out for its 100% on-time delivery rate and comprehensive customization capabilities, making it a strategic partner for buyers requiring bespoke DWS or cross-belt sorting systems. Despite a moderate reorder rate, its high online revenue suggests strong market penetration in logistics automation. Hefei Longbow demonstrates exceptional customer retention (66% reorder rate), indicating robust performance in optical sorting machines for rice, coffee, and grains, though its lower on-time delivery rate warrants closer logistics coordination. Tonten Machinery targets high-capacity waste processing with substantial minimum orders, suitable for municipal or industrial clients needing full-scale plants. Lerford Machine offers entry-level fruit grading equipment at competitive prices but lacks verifiable performance metrics, presenting higher risk for mission-critical deployments.

FAQs

How to verify automated sorting system supplier reliability?

Request proof of certifications (CE, ISO) and third-party inspection reports. Conduct virtual factory audits to assess production lines and quality control procedures. Analyze transaction history, focusing on consistent on-time delivery and post-sale support responsiveness.

What is the typical MOQ and pricing structure?

MOQ varies by application: single units are available for small agricultural sorters ($1,000–$5,500), while industrial waste or logistics systems require 5+ sets with prices exceeding $60,000. Volume discounts are common beyond 10 units, especially for standardized models.

Can suppliers provide customized sorting solutions?

Yes, leading suppliers like Dongguan Mingwei offer full customization of conveyor dimensions, sensor types, sorting logic, and user interface. Provide technical drawings or operational requirements to receive configuration proposals and 3D layouts within 3–5 business days.

What are standard lead times for production and shipping?

Manufacturing lead time averages 25–40 days post-deposit. Air freight takes 5–8 days for sample units; sea freight for full containers requires 20–35 days depending on destination port. Expedited production may reduce build time by 25% with premium fees.

Do suppliers support after-installation maintenance?

Most suppliers offer remote troubleshooting and software updates. Some provide on-site technician dispatch for initial setup or annual maintenance, typically billed separately. Ensure warranty terms cover critical components like cameras, motors, and control boards for at least 12 months.