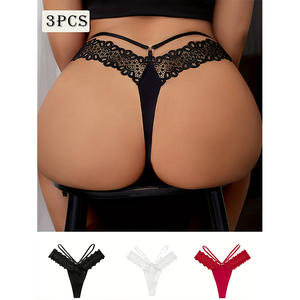

Why Is It Called A G String

Top sponsor listing

Top sponsor listing

About why is it called a g string

Where to Find G-String Underwear Suppliers?

China remains a dominant force in intimate apparel manufacturing, with key production hubs in Guangdong and Fujian provinces driving export-oriented supply chains. Cities such as Shantou, Guangzhou, and Shenzhen host vertically integrated garment facilities specializing in women’s lingerie, including g-string underwear. These clusters benefit from established textile ecosystems, access to synthetic fabrics like microfiber, spandex, and lace, and proximity to major ports, enabling efficient global distribution.

Suppliers in this sector operate within agile production models tailored for fast fashion and private-label demand. Many facilities support seamless knitting, laser cutting, and digital embroidery—techniques critical for producing low-irritation, form-fitting g-string designs. The concentration of dyeing units, trim suppliers, and packaging vendors within 50km radii reduces lead times and enhances customization responsiveness. Buyers typically experience MOQs ranging from 10 to 200 pieces per design, with average production cycles of 20–35 days depending on order complexity and fabric sourcing.

How to Choose G-String Underwear Suppliers?

Procurement decisions should be guided by structured evaluation criteria to ensure product quality, compliance, and operational reliability:

Production & Customization Capability

Assess whether suppliers offer end-to-end customization, including fabric selection (e.g., nylon-spandex blends, ice silk, mesh), color matching (Pantone standards), size grading (XS–XXL or custom charts), and branding options (woven labels, printed packaging, logo embossing). Leading manufacturers provide OEM/ODM services with digital mockup support and prototype sampling within 7–14 days.

Quality Assurance Metrics

Prioritize partners with documented quality control processes. Key performance indicators include:

- On-time delivery rates exceeding 95%

- Response times under 5 hours

- Reorder rates above 15%, indicating customer satisfaction

- Online transaction volumes exceeding US $50,000 annually as a proxy for market validation

While formal certifications (e.g., ISO 9001) are less commonly declared in this segment, consistent performance metrics serve as practical proxies for operational discipline.

Material Sourcing & Compliance

Verify that base materials meet international safety standards for skin contact. Request documentation on OEKO-TEX® certification or REACH compliance for dyes and textiles, particularly for EU and North American markets. Audit fabric durability through stretch recovery tests and seam strength assessments prior to bulk production.

Transaction Security

Utilize secure payment mechanisms such as escrow services when engaging new suppliers. Review historical transaction data where available, focusing on dispute resolution records and sample accuracy. Pre-shipment inspections remain essential for verifying color consistency, stitching integrity, and labeling correctness.

What Are the Top G-String Underwear Suppliers?

| Company Name | Main Products (Listings) | Customization Options | On-Time Delivery | Reorder Rate | Response Time | Annual Online Revenue |

|---|---|---|---|---|---|---|

| Shantou City Bell-Fenny Garments Co., Ltd. | Bras (456), Women's Panties (250) | Color, material, size, design, logo, packaging, label, graphic | 95% | 15% | ≤4h | US $110,000+ |

| Guangzhou Jiyue Apparel Co., Ltd. | Women's Panties (850), Bikinis (173) | Not specified | 100% | <15% | ≤5h | US $1,000+ |

| Guangzhou Cynthia International Trading Co., Ltd. | Women's Panties (496), Bra & Brief Sets (60) | Not specified | 97% | 15% | ≤2h | US $50,000+ |

| Shenzhen Embrace Underwear Co., Ltd. | Not specified | Color, material, size, fabric, seams, design, pattern, logo, mold, packaging, label, graphic | 100% | 20% | ≤3h | US $130,000+ |

| Shenzhen Lin Ge Lei Clothing Co., Ltd. | Women's Panties (335), Bras (188) | Not specified | 82% | <15% | ≤7h | US $3,000+ |

Performance Analysis

Shenzhen Embrace Underwear Co., Ltd. stands out with a 100% on-time delivery rate, 20% reorder rate, and comprehensive customization capabilities, supported by high annual revenue (US $130,000+), indicating strong market acceptance. Guangzhou Jiyue Apparel also reports perfect delivery performance and leads in product listings (850 panties SKUs), though its lower reorder rate suggests room for improvement in customer retention. Shantou City Bell-Fenny offers balanced diversification across bras and panties with solid responsiveness and mid-tier volume performance.

Suppliers based in Shenzhen and Guangzhou demonstrate faster response times (≤3h average), while those with higher reorder rates (>15%) correlate closely with broader customization offerings and established quality systems. Buyers seeking scalable, brand-aligned production should prioritize suppliers with documented design flexibility and proven logistics reliability.

FAQs

What is the typical MOQ for g-string underwear?

Minimum order quantities range from 3 to 200 pieces per style, depending on supplier policy and customization level. Basic styles start at 10–15 pieces, while fully customized designs may require 200+ units to cover setup costs.

How long does production take?

Standard orders require 20–30 days from confirmation to shipment. Custom development—including fabric sourcing, pattern making, and sampling—can extend timelines to 35 days. Expedited production may be available at a premium.

Can I request private labeling?

Yes, most suppliers support private labeling with custom logos, packaging, tags, and graphics. Full OEM/ODM services, including original design development, are offered by top-tier manufacturers like Shenzhen Embrace and Shantou Bell-Fenny.

Are samples available before bulk ordering?

Sample requests are standard. Expect 5–14 days for sample creation, with fees typically ranging from $20–$50 per design. Sample costs may be credited toward subsequent orders.

What materials are commonly used in g-string production?

Common materials include nylon-spandex blends, polyester-mesh, ice silk, and lace trims. Seamless knitting technology is widely used to minimize chafing and enhance fit. Suppliers often provide fabric swatches upon request for evaluation.