Wire Harness Assembly Automation

Top sponsor listing

Top sponsor listing

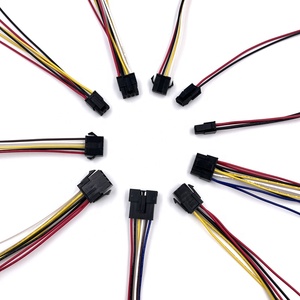

About wire harness assembly automation

Where to Find Wire Harness Assembly Automation Suppliers?

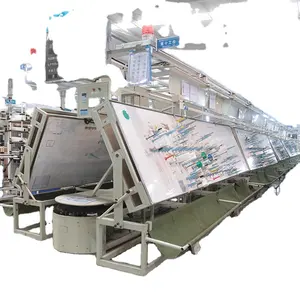

China remains the global epicenter for wire harness assembly automation manufacturing, with key production hubs concentrated in Guangdong and Jiangsu provinces. Shenzhen and Dongguan in Guangdong province host advanced electronics manufacturing clusters, integrating automated assembly equipment with precision wiring component production. These regions benefit from mature supply chains for connectors, terminals, and insulating materials, enabling rapid prototyping and scalable production runs. Proximity to Tier-1 automotive and industrial electronics OEMs drives innovation in semi-automated and fully automated harness assembly systems.

The industrial ecosystem supports both component-level manufacturing and turnkey automation solutions. Suppliers leverage vertical integration—combining CNC stamping, molding, crimping, and testing under one roof—to reduce lead times by up to 30% compared to fragmented international sourcing. Buyers gain access to facilities equipped with automated insertion, laser marking, and continuity testing systems, ensuring consistent quality across high-volume orders. Typical advantages include MOQ flexibility (as low as 5–10 pieces for prototypes), competitive pricing due to localized labor and material costs, and fast turnaround for custom engineering projects.

How to Choose Wire Harness Assembly Automation Suppliers?

Selecting reliable partners requires a structured evaluation of technical capability, operational efficiency, and transactional reliability:

Technical and Production Capabilities

Prioritize suppliers with demonstrated experience in automated wire processing, including terminal crimping, ultrasonic welding, and inline inspection systems. Verify access to semi-automatic or fully automatic machinery such as wire cut-strip machines, crimping presses, and shrink-tube insertion units. For custom automation solutions, confirm in-house engineering teams capable of designing bespoke assembly lines tailored to specific harness geometries and volume requirements.

Quality Assurance and Compliance

Ensure adherence to IPC/WHMA-A-620 standards for cable and wire harness assemblies. While formal ISO 9001 certification may not be explicitly listed in all supplier profiles, consistent on-time delivery rates (≥97%) and documented testing procedures—including continuity, insulation resistance, and pull-force testing—are strong proxies for process control. RoHS compliance is standard for export-ready components.

Operational Metrics and Responsiveness

Evaluate performance indicators:

- On-time delivery rate ≥98% indicates reliable logistics management

- Average response time ≤2 hours reflects proactive customer engagement

- Reorder rates above 30% suggest high client retention and satisfaction

- Online revenue exceeding US $100,000 signals established market presence

Cross-reference product listings with actual machine offerings and customization options to assess specialization depth. Request facility videos or audit reports when scaling to high-volume contracts.

What Are the Best Wire Harness Assembly Automation Suppliers?

| Company Name | Main Products | Automation Offerings | On-Time Delivery | Response Time | Reorder Rate | Revenue Tier | Customization Support |

|---|---|---|---|---|---|---|---|

| DONGGUAN KAWEEI ELECTRONIC CO.,LTD | Custom Cable Assemblies, Electronic Wire Harnesses | Automated assembly for automotive and industrial applications | 100% | ≤2h | 100% | US $120,000+ | Color, size, drawing, logo, packaging, label |

| Taixing Haozhuo Precision Photoelectric Technology Co., Ltd. | Wiring Harness, Connectors, Power Cables | High-volume automated transmission and 12V harness production | 100% | ≤1h | 33% | US $1,000+ | OEM/ODM supported |

| Shenzhen Changyingtong Precision Electronics Co., Ltd. | Wiring Harness, Connectors | Custom automotive and energy harnesses with automated testing | 100% | ≤2h | 20% | US $30,000+ | OEM/ODM supported |

| Shenzhen Tecfd Technology Co., Ltd. | Cable Manufacturing Equipment, Crimping Machines | Semi-automatic and full-auto wire harness assembly machines | 100% | ≤5h | 18% | US $10,000+ | Machine customization available |

| Shenzhen Syikai Electronics Co., Ltd. | Wiring Harness, Terminal Blocks, Cables | Standard and custom harnesses with basic automation support | 56% | ≤6h | 20% | US $40,000+ | Limited customization |

Performance Analysis

DONGGUAN KAWEEI stands out with a 100% reorder rate and comprehensive customization capabilities, indicating strong customer loyalty and flexible production planning. Taixing Haozhuo leads in responsiveness (≤1h) and maintains a robust 33% reorder rate, reflecting consistent service quality. Shenzhen-based manufacturers offer diverse product portfolios but vary significantly in delivery reliability—Tecfd provides automation equipment directly, positioning it as a solution provider rather than a harness producer. Suppliers with 100% on-time delivery records demonstrate disciplined workflow management, critical for just-in-time manufacturing environments. For buyers seeking integrated automation solutions, prioritize companies offering both harness fabrication and machine supply to streamline integration and maintenance.

FAQs

How to verify wire harness automation supplier reliability?

Assess on-time delivery history, response speed, and reorder rate as key performance indicators. Request evidence of in-house testing protocols, such as electrical continuity checks and mechanical durability tests. For automation equipment suppliers, verify machine specifications against industry standards like CE or IEC 60204-1.

What are typical MOQs and pricing structures?

MOQs range from 5–100 pieces depending on complexity. Simple harnesses start at $0.10/unit, while engineered solutions (e.g., transmission or EV harnesses) range from $0.80–$10.00. Automation machines have higher entry costs ($199–$1,999 per set), typically sold in multi-set configurations.

Do suppliers support customization?

Yes, most suppliers offer OEM/ODM services including connector type selection, wire gauge specification, jacket color, labeling, and packaging. Full customization requires technical drawings or samples; lead time varies from 15–30 days based on design complexity.

What is the average lead time for samples and bulk orders?

Sample production takes 7–15 days. Bulk order fulfillment averages 20–35 days, depending on automation level and inspection requirements. Expedited processing is available with confirmed purchase commitments.

Can suppliers handle global shipping and compliance?

Yes, experienced exporters manage international logistics via air or sea freight. Confirm packaging standards (ESD-safe, moisture barrier) and documentation for customs clearance. Most products comply with RoHS; additional certifications (UL, CSA) require prior agreement and may extend lead time.