Wire Loop Tool Exporter

1/23

1/23

1/1

1/1

1/12

1/12

1/6

1/6

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/1

1/1

1/3

1/3

0

0

1/20

1/20

1/16

1/16

0

0

1/3

1/3

1/24

1/24

1/3

1/3

About wire loop tool exporter

Where to Find Wire Loop Tool Exporters?

China remains the dominant manufacturing hub for wire loop tools, with key production clusters in Guangdong, Hebei, and Jiangsu provinces. These regions host vertically integrated supply chains that combine raw material processing, precision forging, heat treatment, and packaging under one ecosystem. Dongguan and Shenzhen in Guangdong specialize in high-precision hand tools used in jewelry making and electrical applications, leveraging automated CNC machining and quality control systems to support export volumes. Hebei’s industrial base focuses on heavy-duty wire rope slings and cable forming tools, benefiting from proximity to major steel producers, which reduces input costs by 15–20% compared to offshore alternatives.

The concentration of component suppliers, tooling workshops, and logistics networks within 50km radii enables rapid prototyping and scalable production. Exporters typically maintain lean lead times of 15–30 days for standard orders, with customization capabilities across material grade, diameter, length, and branding. Buyers benefit from competitive pricing—ranging from $0.28 to $2.49 per unit depending on specification—and flexible MOQs starting as low as 5–10 pieces for niche tool variants.

How to Choose Wire Loop Tool Exporters?

Selecting reliable exporters requires a structured evaluation of technical capability, transaction history, and operational responsiveness:

Quality Management Verification

While formal ISO 9001 certification is not universally declared among listed suppliers, performance metrics such as on-time delivery rates (ranging from 84% to 100%) and response times (≤1h to ≤8h) serve as indirect indicators of process discipline. Prioritize suppliers reporting ≥94% on-time delivery and sub-6-hour average response times, particularly for time-sensitive procurement cycles.

Production and Customization Capacity

Assess technical flexibility based on documented customization options:

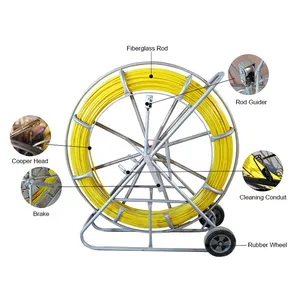

- Material specifications: carbon steel, galvanized steel, fiberglass-reinforced polymers

- Dimensional adaptability: cable diameter, loop spacing, total length, automatic tightening mechanisms

- Branding services: logo imprinting, custom packaging, label design, color coding

- Drawing-based manufacturing: ability to produce from technical blueprints or CAD files

Suppliers like Hebei Long Zhuo Trade Co., Ltd. and Shenzhen Ruize Technology Co., Ltd. explicitly list engineering support for OEM/ODM configurations, indicating stronger R&D integration.

Transaction Risk Mitigation

Evaluate reorder rates as a proxy for customer satisfaction—suppliers with ≥20% repeat order activity (e.g., Dongguan Xinrong Hardware Products Co., Ltd. at 31%, Shenzhen Ruize at 20%) demonstrate consistent product quality and service reliability. Cross-reference online revenue data where available; top-tier exporters report annual digital sales exceeding US $230,000, suggesting established international distribution channels.

What Are the Best Wire Loop Tool Exporters?

| Company Name | Location | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Min. Order Quantity | Price Range (USD) | Customization Support |

|---|---|---|---|---|---|---|---|---|

| Dongguan Xinrong Hardware Products Co., Ltd. | Guangdong, CN | 84% | ≤2h | 31% | $370,000+ | 70–100 pcs | $0.28–0.60 | Yes (size, material, packaging, logo) |

| Zhangjiagang Zhishi Hardware Tools Manufacturing Co., Ltd. | Jiangsu, CN | 100% | ≤6h | - | - | 10 pcs | $2.29–2.49 | Limited (product-specific) |

| Hebei Long Zhuo Trade Co., Ltd. | Hebei, CN | 100% | ≤2h | <15% | $230,000+ | 1–10 pcs | $8.50–68.00 | Yes (color, size, logo, packaging) |

| Shenzhen Ruize Technology Co., Ltd. | Guangdong, CN | 94% | ≤8h | 20% | $260,000+ | 5–10 pcs | $0.82–2.40 | Yes (material, size, logo, drawings) |

| CROSSEDGE CORPORATION | Unknown | 86% | ≤1h | - | $4,000+ | 2–5 pcs | $0.55–12.99 | Specialized (hair extension tools) |

Performance Analysis

Zhangjiagang Zhishi and Hebei Long Zhuo achieve perfect 100% on-time delivery records, signaling robust production planning despite differing market focuses—jewelry tools versus industrial pulling equipment. Dongguan Xinrong stands out with the highest reported reorder rate (31%) and strong digital revenue ($370K+), indicating sustained buyer trust and effective export operations. Shenzhen Ruize offers the lowest MOQs (5 pieces) and competitive pricing, making it suitable for small-batch trials or specialized tooling needs. CROSSEDGE CORPORATION caters to a niche segment (hair extension tools), reflected in ultra-low MOQs but limited scalability due to modest revenue volume.

FAQs

How to verify wire loop tool exporter reliability?

Analyze response consistency, on-time delivery history, and reorder rate trends. Request evidence of quality control processes, such as material test reports or finished product inspections. For high-volume contracts, conduct virtual factory audits to confirm production lines and inventory management systems.

What is the typical lead time for wire loop tool orders?

Standard order fulfillment ranges from 15 to 25 days after deposit confirmation. Custom designs may require an additional 7–14 days for tooling adjustments or sample validation. Air shipping adds 5–10 days globally; sea freight takes 25–40 days depending on destination port.

Can exporters provide free samples?

Sample availability depends on order intent. Many suppliers offer paid samples (priced at 1x–2x unit cost) refundable against future bulk orders. Truly free samples are rare but possible for high-potential buyers demonstrating long-term demand.

What materials are commonly used in wire loop tools?

Carbon steel dominates for strength and durability, especially in pliers and looping tools. Galvanized coatings enhance corrosion resistance for outdoor or marine applications. Fiberglass-reinforced polymers are used in electrician-grade puller kits to ensure non-conductivity.

How to initiate customization requests?

Submit detailed specifications including required dimensions (diameter, length, spacing), material type, load capacity, and visual branding elements. Suppliers with engineering teams can return technical drawings or 3D models within 3–5 business days for approval prior to production.