Wire Net Making Machine

CN

CN

About wire net making machine

Where to Find Wire Net Making Machine Suppliers?

China remains the global epicenter for wire net making machine manufacturing, with key production clusters concentrated in Hebei and Shandong provinces. These regions host vertically integrated supply chains that combine raw material processing, precision machining, and final assembly under one ecosystem. Anping County in Hebei alone accounts for over 70% of China’s wire mesh machinery output, supported by a dense network of component suppliers and metallurgical service providers within a 50km radius.

The industrial infrastructure enables rapid prototyping and scalable production, with lead times averaging 30–45 days for standard configurations. Localized access to steel mills and motor manufacturers reduces material procurement costs by 18–25% compared to offshore alternatives. Buyers benefit from flexible MOQs—most suppliers offer single-set orders—while maintaining cost efficiency through standardized modular designs. The region also supports high degrees of customization in mesh geometry, wire diameter (ranging from 0.5mm to 6mm), and automation levels, catering to diverse applications such as fencing, construction reinforcement, and agricultural netting.

How to Choose Wire Net Making Machine Suppliers?

Selecting reliable suppliers requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Design Capability

Confirm adherence to international safety and performance benchmarks, including CE marking for electrical systems and ISO-compliant quality control processes. Evaluate design flexibility: leading suppliers support customizations in mesh size, wire type (GI, PVC-coated, stainless steel), machine width, and automation level (semi-automatic to fully automatic). Request detailed technical drawings and verify compatibility with required inlet/outlet wire diameters and power specifications.

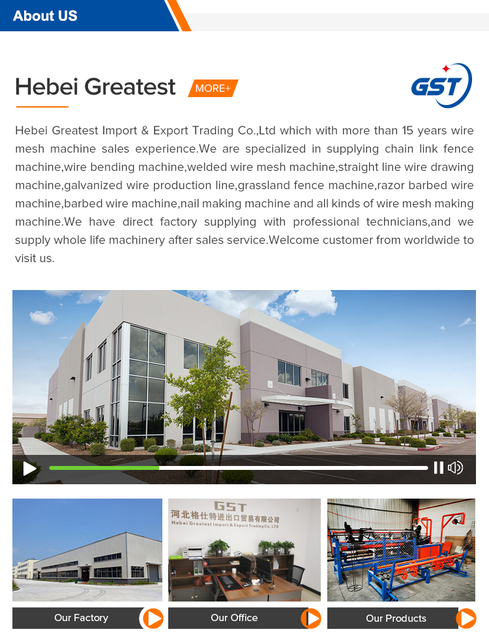

Production Infrastructure Assessment

Prioritize manufacturers with documented engineering capacity and end-to-end production control. Key indicators include:

- In-house R&D teams capable of adapting machine configurations

- Integrated fabrication capabilities (CNC machining, welding, gearbox assembly)

- Minimum factory area exceeding 3,000m² for stable batch production

Cross-reference these metrics with on-time delivery rates—target suppliers maintaining ≥98% fulfillment punctuality.

Quality Assurance and Transaction Security

Demand verifiable quality management practices, including pre-shipment inspection protocols and testing documentation for critical components like motors and drive systems. Utilize secure payment mechanisms such as trade assurance or escrow services to mitigate risk. Conduct sample testing to validate mesh consistency, weld strength, and operational stability before full-scale ordering.

What Are the Best Wire Net Making Machine Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Tangshan Shuoen International Trade Co., Ltd. | Tangshan, CN | Wire Mesh Machines, Steel Mesh | US $4.1M+ | 100% | ≤2h | 36% | Yes | $1,800–3,000 |

| Shijiazhuang Tops Hardware Manufacturing Co., Ltd. | Shijiazhuang, CN | Wire Mesh Machines, Hardware | US $770K+ | 100% | ≤2h | 100% | Yes | $480–21,500 |

| Hebei Houhong Metal Wire Mesh Products Co., Ltd. | Anping, CN | Wire Mesh Making Machines (148) | Not disclosed | 100% | ≤2h | Not available | Limited | $3,000–5,000 |

| Anping County Laien Wire Mesh Machine Manufacturing Co., Ltd. | Anping, CN | Welded Mesh Machines, Fence Equipment | US $30K+ | 100% | ≤1h | <15% | Yes | $5,000–38,000 |

| Hebei Shunmao Technology Co., Ltd. | Hebei, CN | Wire Mesh Machines (78), Coating Machinery | US $200+ | 100% | ≤4h | Not available | Yes | $8,500–35,000 |

Performance Analysis

Tangshan Shuoen and Shijiazhuang Tops demonstrate strong market traction, with high reorder rates (36% and 100%, respectively) indicating customer satisfaction and product reliability. Shijiazhuang Tops stands out for its wide price range and full customization support, serving both entry-level and industrial-grade requirements. Hebei Houhong offers volume-focused production with 148 listed machine variants, though limited reorder data suggests lower repeat engagement. Anping Laien excels in responsiveness (≤1h average reply time) and high-end automation solutions, with machines reaching up to $38,000 for BRC welded mesh systems. Hebei Shunmao targets specialized applications like gabion and barbed wire production, commanding premium pricing backed by robust build quality.

FAQs

How to verify wire net making machine supplier reliability?

Validate certifications (CE, ISO), request facility audit reports, and analyze historical transaction data. Assess responsiveness, order fulfillment consistency, and technical documentation availability. Prioritize suppliers with transparent communication and proven export experience.

What is the typical lead time for wire net making machines?

Standard models are typically delivered within 30–45 days after order confirmation. Custom-built systems may require 50–70 days depending on complexity. Air freight options reduce shipping time to 5–10 days but increase logistics costs significantly.

Do suppliers offer customization for mesh specifications?

Yes, most established suppliers provide full customization for mesh size, wire diameter (0.5–6mm), material type (galvanized iron, stainless steel, PVC-coated), machine width, and automation level. Technical drawings and operational parameters must be submitted for accurate quoting.

Can I request a sample or prototype before bulk ordering?

Suppliers generally allow sample production runs for validation. Costs vary based on machine type, with partial reimbursement upon placement of full orders. Prototype development typically takes 20–30 days, including design review and testing phases.

What are common payment and shipping terms?

Common payment methods include T/T, L/C, and platform-backed trade assurance. FOB terms are standard, with CIF available upon request. Sea freight is recommended for heavy machinery due to cost efficiency, while air shipping suits urgent sample deliveries.