Wire Terminal Connectors Producer

Top sponsor listing

Top sponsor listing

About wire terminal connectors producer

Where to Find Wire Terminal Connectors Producers?

China remains the dominant hub for wire terminal connectors manufacturing, with key industrial clusters concentrated in Zhejiang and Guangdong provinces. Wenzhou and Yueqing in Zhejiang province host a high density of electrical component manufacturers, supported by mature supply chains for copper, nylon insulation materials, and precision stamping equipment. These regions benefit from vertically integrated production ecosystems—enabling seamless transitions from raw material sourcing to final assembly within localized networks.

The cluster advantage translates into operational efficiencies: lead times for standard orders average 15–25 days, while customized configurations can be fulfilled within 30 days. Localized access to tooling workshops, plating facilities, and packaging suppliers reduces production costs by 20–30% compared to offshore alternatives. Buyers also gain flexibility in order volume, with many producers accommodating MOQs as low as 100 pieces for insulated terminals and crimp connectors.

How to Choose Wire Terminal Connectors Producers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Quality & Compliance Verification

Prioritize suppliers providing evidence of compliance with international standards such as CE, RoHS, and ISO 9001. While not all producers list formal certifications in public profiles, consistent adherence to these benchmarks is indicated by product conformity declarations, material traceability, and standardized testing protocols for conductivity, tensile strength, and insulation resistance.

Production Capability Assessment

Evaluate core manufacturing competencies through the following indicators:

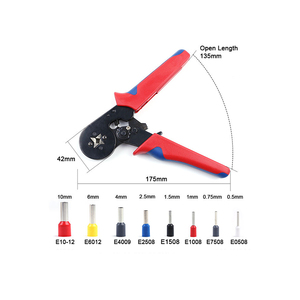

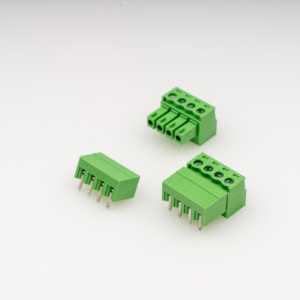

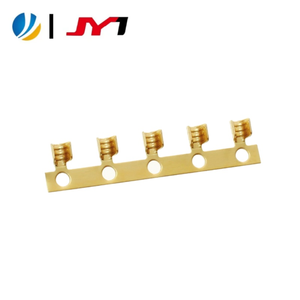

- Customization capacity: Support for variable parameters including wire gauge (AWG 16–24 typical), terminal color coding, plating type (tin, nickel, or silver), and packaging configuration

- In-house tooling and stamping lines to support rapid prototyping and design iteration

- Minimum facility output exceeding 500,000 units per month for reliable scalability

- Integration of automated inspection systems for batch consistency

Cross-reference on-time delivery performance (target ≥95%) and response time (ideally ≤3 hours) to assess operational reliability.

Procurement Risk Mitigation

Utilize structured sampling procedures before bulk ordering—request physical samples to verify material quality, crimp integrity, and insulation durability under thermal cycling. Confirm reorder policies and return conditions upfront. For high-volume contracts, initiate production audits via video walkthroughs to validate factory infrastructure and workflow organization.

What Are the Leading Wire Terminal Connectors Producers?

| Company Name | Verified Type | Main Products | Customization Options | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|

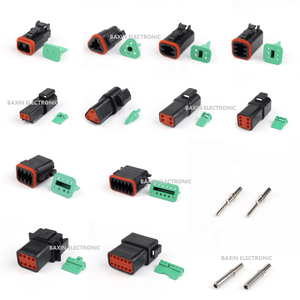

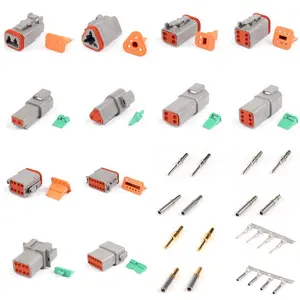

| Wenzhou Baxin Import & Export Co., Ltd. | Custom Manufacturer | Connectors, Terminals, Plier, Wiring Harness, Auto Connectors | Color, material, size, logo, packaging, label, graphic | 100% | ≤3h | <15% | US $140,000+ |

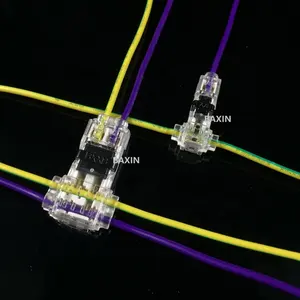

| Ningbo Selamp Electronic Tech Co., Ltd. | Brand Holder | Wire Terminal Connectors, PCB Edge Clamps, T-Type Splitters | Cable range, color, size, packaging, label | 100% | ≤2h | <15% | US $20,000+ |

| Yueqing Hoored Electric Co., Ltd. | Unspecified | Terminals, Cable Ties, Terminal Blocks, Connectors | Limited data | 95% | ≤2h | 33% | US $10,000+ |

| Yueqing Guchuan Eletric Co., Ltd. | Unspecified | U-Shape Terminals, Bullet Connectors, Crimp Terminals | Limited data | 95% | ≤5h | <15% | US $60,000+ |

| Yueqing Rendian Electric Appliance Co., Ltd. | Unspecified | Insulated Terminals, Copper Boots, Power Cables | Limited data | 33% | ≤4h | 33% | US $1,000+ |

Performance Analysis

Wenzhou Baxin and Ningbo Selamp demonstrate strong reliability with 100% on-time delivery and sub-3-hour response times, positioning them as preferred partners for time-sensitive procurement. Wenzhou Baxin leads in customization breadth and online sales volume, indicating robust production infrastructure. Ningbo Selamp’s brand holder status suggests potential IP ownership or exclusive distribution rights, advantageous for private labeling.

Yueqing-based manufacturers show mixed performance: while Hoored and Guchuan maintain 95% delivery rates, Rendian's 33% on-time fulfillment raises concerns about production consistency despite comparable reorder rates. Suppliers with lower reorder rates (<15%) may focus on one-off export transactions rather than long-term buyer relationships, which can impact post-sale support availability.

FAQs

What materials are commonly used in wire terminal connectors?

Copper (especially tin-plated copper) is standard for conductive components due to its high conductivity and corrosion resistance. Insulation sleeves typically use nylon or PVC, with operating temperature ranges from -40°C to 105°C. High-grade variants may incorporate phosphor bronze for enhanced spring characteristics in quick-disconnect terminals.

What are typical MOQs and pricing ranges?

MOQs vary by supplier and product type: basic insulated terminals start at 100 pieces ($0.01–$0.08/unit), while specialized connectors (e.g., PCB clamps or boot terminals) may require 500–1,000 units at $0.13–$2.50 per piece. Bulk pricing is negotiable for orders exceeding 10,000 units, with discounts averaging 10–20%.

Can suppliers provide custom branding and packaging?

Yes, leading producers offer OEM services including custom color coding, laser logo marking, branded packaging, and multi-language labels. Minimum requirements for full customization typically begin at 5,000 units per SKU.

How long does sample production take?

Standard samples are dispatched within 5–7 days. Custom designs requiring new molds or plating specifications take 10–15 days. Air shipping adds 3–7 days depending on destination region.

What are key considerations for global shipping?

Confirm Incoterms (FOB, CIF, or DDP) during negotiation. Most suppliers handle export documentation and partner with freight forwarders for sea or air consolidation. For regulated markets (EU, US), ensure products meet RoHS and REACH compliance for customs clearance. Use tracked logistics with insurance coverage for high-value shipments.