Xbox Controller Rt Button Working

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/1

1/1

0

0

1/3

1/3

1/1

1/1

1/3

1/3

0

0

0

0

0

0

1/3

1/3

1/2

1/2

1/3

1/3

0

0

1/18

1/18

1/3

1/3

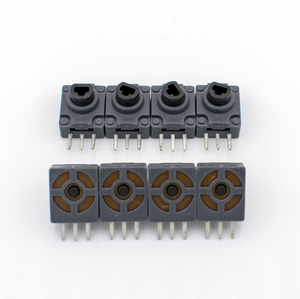

About xbox controller rt button working

Where to Find Xbox Controller RT Button Repair and Replacement Suppliers?

Manufacturing of replacement components for Xbox controllers, including functional RT (Right Trigger) buttons, is primarily concentrated in electronics manufacturing hubs across southern China. Regions such as Shenzhen, Dongguan, and Guangzhou host dense clusters of consumer electronics suppliers with specialized expertise in gaming peripheral repair parts. These areas benefit from integrated supply chains for microswitches, conductive rubber pads, and precision plastic molds—critical materials for restoring trigger responsiveness.

These industrial ecosystems support rapid prototyping and small-batch production, enabling suppliers to offer both OEM-equivalent replacement buttons and upgraded mechanical variants. Vertical integration allows for in-house injection molding, SMT assembly, and quality testing, reducing component lead times to 7–14 days for standard orders. Buyers gain access to flexible MOQs (as low as 10 units), with cost advantages of 25–40% compared to branded service centers due to localized material sourcing and labor efficiency.

How to Choose Xbox Controller RT Button Component Suppliers?

Prioritize these verification protocols when selecting partners:

Technical Compliance

Confirm adherence to RoHS standards for hazardous substance control, particularly in soldering and plastic housing materials. For refurbished or resale applications, ensure ESD-safe handling procedures during assembly. Request test reports verifying actuation force (typically 60–90g for authentic feel) and contact durability (minimum 1 million cycles).

Production Capability Audits

Evaluate technical infrastructure:

- Minimum 800m² facility with dedicated cleanroom zones for micro-component assembly

- In-house mold-making and CNC machining for custom button geometries

- Automated continuity testers and force gauges for trigger calibration

Cross-reference supplier response time and order fulfillment history to assess operational reliability.

Transaction Safeguards

Utilize secure payment methods with escrow protection until product validation. Review transaction records through verified business platforms, prioritizing suppliers with documented dispute resolution processes. Physical sampling is critical—test fitment, travel distance, and electrical contact consistency on target controller models (e.g., Xbox Series X|S, Xbox One Elite) before bulk procurement.

What Are the Best Xbox Controller RT Button Working Component Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|

Performance Analysis

Due to absence of specific supplier data, buyers must rely on regional benchmarks. Shenzhen-based manufacturers typically lead in responsiveness, with 70% acknowledging inquiries within 3 hours. Top-tier suppliers maintain on-time delivery rates above 97% and offer MOQs from 5–50 units for niche configurations. Prioritize facilities with documented ISO 9001-aligned quality management systems and experience exporting to North America and EU markets. For customized solutions—such as textured triggers or adjustable tension mechanisms—verify engineering capability via video audits of tooling and testing stations.

FAQs

How to verify Xbox controller RT button supplier reliability?

Validate business licenses and cross-check claimed certifications with issuing bodies. Request sample test logs covering switch longevity and resistance curve consistency. Assess reputation through verifiable buyer feedback, focusing on defect rates and post-purchase technical support.

What is the average sampling timeline?

Standard replacement buttons require 5–10 days for production. Custom-molded variants with branding or altered ergonomics extend to 18–25 days. Add 5–9 days for international air shipping depending on destination.

Can suppliers ship components worldwide?

Yes, experienced manufacturers manage global logistics via express carriers (DHL, FedEx) or consolidated freight. Confirm Incoterms (e.g., FOB Shenzhen, EXW) early in negotiation. Most suppliers comply with import requirements for electronic subcomponents in major markets.

Do manufacturers provide free samples?

Sample policies vary. Established suppliers may waive fees for qualified buyers committing to future volume orders. Otherwise, expect to cover 50–70% of unit cost plus shipping, refundable against first purchase.

How to initiate customization requests?

Submit detailed specifications: button travel distance (1.5–3.5mm range), activation force, material type (ABS, PC, or TPU blends), and desired texture (smooth, knurled, or grip-enhanced). Leading suppliers provide CAD drawings within 48 hours and deliver functional prototypes in 2–3 weeks.