Yoyofactory String

1/15

1/15

1/19

1/19

1/3

1/3

About yoyofactory string

Where to Find Yoyofactory String Suppliers?

China remains the central hub for manufacturing performance-grade strings under the yoyofactory designation, with key suppliers concentrated in Guangdong and Zhejiang provinces. These regions host vertically integrated production networks specializing in precision-wound string assemblies for musical instruments and yo-yo accessories. Shenzhen and Guangzhou-based firms leverage proximity to raw material hubs—particularly nickel alloys, phosphor bronze, and synthetic polymers—enabling tighter control over material consistency and coating processes such as nano-coating and pure silver plating.

Suppliers operate within mature industrial ecosystems where component sourcing, winding technology, and packaging are co-located, reducing lead times by up to 30% compared to offshore alternatives. The average production cycle for standard string sets ranges from 15–25 days post-order confirmation, with MOQs typically starting at 5–20 units depending on product type. Bulk orders benefit from automated winding lines capable of maintaining ±0.01mm gauge tolerance across high-volume runs. Export infrastructure supports global distribution, with primary buyers located in North America, Europe, and Southeast Asia.

How to Choose Yoyofactory String Suppliers?

Procurement decisions should be guided by objective evaluation criteria focused on quality assurance, operational responsiveness, and transactional reliability:

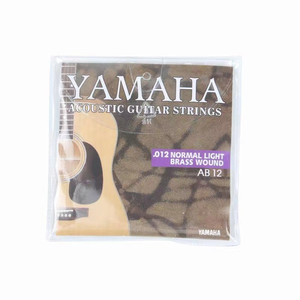

Material & Technical Specifications

Verify wire composition (e.g., nickel alloy, pure silver, stainless steel) and gauge accuracy through supplier-provided test reports or third-party lab verification. For electric guitar or bass strings, confirm anti-corrosion treatments like nano-coating or polymer encapsulation. Yo-yo replacement strings require tensile strength ratings compatible with high-speed play; request durability testing data where applicable.

Production and Quality Control

Assess supplier capabilities based on the following indicators:

- On-time delivery rate exceeding 97%

- Response time under 12 hours (top-tier suppliers respond within ≤1–5 hours)

- Evidence of consistent reorder rates (indicative of customer satisfaction)

- Customization capacity for gauge, length, winding pattern, and packaging

Certifications such as ISO 9001 are not explicitly listed but can be inferred from disciplined process metrics. Prioritize suppliers with documented quality inspection protocols, especially those offering batch-specific consistency.

Transaction Security and Sampling

Utilize secure payment mechanisms such as escrow services to mitigate risk. Request physical samples before large-scale orders to evaluate tactile performance, tuning stability, and packaging integrity. Note that sample costs vary—from $0.30 to $17.20 per unit—depending on material complexity (e.g., pure silver violin strings command premium pricing). Lead time for sampling averages 7–14 days, including international shipping via express courier.

What Are the Best Yoyofactory String Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Min. Order | Price Range (USD) |

|---|---|---|---|---|---|---|---|

| Shenzhen Donlis Electric-Sound Technology Co., Ltd. | Guitar Strings, Bass Strings, Instrument Accessories | US $180,000+ | 98% | 28% | ≤5h | 10–20 pcs/sets | $1.06–$4.58 |

| Guangzhou Zhanqiao Musical Instrument Co., Ltd. | Violin Strings, Banjo Strings, Electric Bass Sets | US $6,000+ | 98% | 15% | ≤1h | 5 pcs/sets | $0.56–$17.20 |

| Shantou Chenghai Zhuochen Trading Firm | Yo-Yo Kits, Replacement Strings (Bulk Packaging) | US $860,000+ | 100% | 33% | ≤3h | 480–720 boxes | $0.29–$0.42 |

| Shenzhen Qiyu Technology Co., Ltd. | Yoyo Strings, Professional Spin Tops, Accessories | US $20,000+ | 90% | <15% | ≤7h | 2–50 pcs | $0.99–$7.49 |

| Yiwu Aiyue Musical Instrument Co., Ltd. | Violin Strings, Guitar Strings, Custom Packaging | US $700,000+ | 99% | <15% | ≤12h | 2–100 cartons | $1.10–$4.87 |

Performance Analysis

Shenzhen Donlis stands out for balanced pricing and reliable fulfillment in the musical instrument string segment, particularly for nickel-alloy electric sets. Guangzhou Zhanqiao offers the lowest entry MOQs and fastest response times, ideal for small retailers or niche importers, though its lower reorder rate suggests potential gaps in long-term satisfaction. Shantou Chenghai Zhuochen leads in bulk yo-yo string supply with a perfect on-time delivery record and high reorder volume, indicating strong logistics execution despite minimal customization focus. Yiwu Aiyue demonstrates extensive export experience with the highest online revenue among peers and supports full customization—including color, logo, and packaging—making it optimal for private-label procurement. Shenzhen Qiyu caters to performance-grade yo-yo markets with higher-priced competitive models, though its sub-15% reorder rate warrants due diligence into post-sale support.

FAQs

How to verify yoyofactory string supplier reliability?

Evaluate on-time delivery history, reorder rate, and response speed as proxies for operational discipline. Request product specifications, material certifications, and sample batches to assess consistency. Confirm packaging standards and labeling compliance for destination-market retail readiness.

What is the typical MOQ for string products?

MOQ varies by product type: 5–20 pieces/sets for individual string packs, 480+ boxes for promotional yo-yo kits, and 100+ cartons for wholesale instrument strings. Some suppliers allow mixed SKUs at incremental cost.

Can suppliers customize string packaging and branding?

Yes, select manufacturers like Yiwu Aiyue offer full customization options including color, logo imprinting, material selection, and graphic design for retail-ready packaging. Minimum thresholds may apply.

What are common materials used in yoyofactory strings?

Guitar and bass strings commonly use nickel alloy, pure nickel, or stainless steel. Violin strings may feature pure silver winding or synthetic cores. Yo-yo replacement strings are typically made from durable nylon or polyester fibers calibrated for tensile strength.

Are samples available before placing bulk orders?

Most suppliers provide samples at quoted prices, often refundable upon order placement. Sample lead time is typically 7–14 days, with express shipping recommended for timely evaluation.