All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(2984 products available)

Dense foam comes in different types. They include:

Memory Foam

Memory foam is also referred to as viscoelastic foam. It is renowned forits ability to conform to body shape. It evenly distributes weight thus alleviating pressure points. This feature makes it popular for foams for beds and cushions. Memory foam also regains its original shape after use. This gives it a high-density rating. However, its density can vary, generally ranging between 4 to 6 pounds per cubic foot.

Polyurethane Foam

High-resilient (HR) polyurethane foam is manufactured by altering the typical polyurethanecell structure.This results in a denser, more supportive material. The density of this foam normally ranges from 2 to 4 pounds per cubic foot. Polyurethane foam is widely used in a variety of applications that include furniture, automotive seating, and insulation.

Latex Foam

Latex foam can be manufactured from natural rubber tree sap or synthetic materials. It offers exceptional support and durability. Also, it has a higher density compared to conventional foams. Generally, latex foam comes in two types. They are Dunaprocessed as well as Talalay latex foam. Dunaprocessed foam is thicker and denser. It enhances the firmness of mattresses. On the other hand, Talalay latex foam comes with a lighter texture. It adds a gentler feel.

Acoustic Foams

Sound foam features open-cell structures that are designed for sound absorption. This helps in minimizing echo and noise. Acoustic foamhas a density ranging from 1 to 3 pounds per cubic foot. Its main purpose isused in recording studios, cinemas, and auditoriums. This is due to its exceptional soundproofing abilities.

Memory Gel Foam

This foam integrates the properties of memory foam and gel technology. It offers enhanced breathability and temperature regulation. The gel particles dissipate heat. Therefore, the foam remains cool and comfortable, even after extended use. Typically, memory gel foam has a density of approximately 3 to 5 pounds per cubic foot.

High-density foam is packed with numerous features. They include:

Exceptional Support

High-density foam provides unparalleled support. It does this by conforming to the body’s contours. This feature ensures proper spinal alignment. Also, it alleviates pressure points. As a result, users enjoy superior comfort. It is ideal for cushions for chair and mattresses where support is key.

Durability and Longevity

The notable resistance to sagging enhances its durability. This allows the foam to retain its shape and performance over a long period. Users can therefore invest in high-density foam products without the worry of needing replacements too soon.

Versatility

High-density foam is remarkably versatile. It is widely used in furniture, automotive interiors, and even medical applications. Its adaptability makes it a preferred choice across multiple industries. This caters to both commercial and residential customers alike.

Hygienic and Allergy-Free

The closed-cell structure of high-density foam inhibits the accumulation of dust mites, allergens, and bacteria. This quality promotes a healthier living environment. It makes it a choice for those with allergies or respiratory issues. Also, it is low-maintenance and easy to clean.

Energy Absorption

This feature helps in reducing impact forces. It is essential in applications such as sports gear and automotive seats where safety is a major concern. Also, it adds to the overall comfort in seating and sleeping products.

There are diverse applications of memory foam mattress in commercial settings. They include:

Furniture Industry

High-density foam is a key component in the production of upscale furniture. It is notably used in sofa cushions and upholstery. The foam offers a resilient, luxurious filling that ensures both comfort and support. This allows users to enjoy a seating surface that remains plush and inviting, even with regular use.

Automotive Interiors

Automakers incorporate high-density foam in car seats to enhance passenger experience. Since this foam contours to the body, it provides ergonomic support during long drives. Its durability extends the lifespan of the seats. In addition, the foam withstands heavy usage without losing its shape.

Mattresses and Bedding

High-density foam plays a pivotal role in the mattress industry. Manufacturers use it to create memory foam mattresses which have a supportive, sleep-friendly surface. The deep conforming ability provides pressure relief. Therefore, customers enjoy a restful night’s sleep. Additionally, bedding companies use the foam in mattress toppers and pillows for added comfort.

Sports and Fitness Gear

High-density foam cushionsareused in gym mats, balance boards, and other fitness equipment. These cushions offer support during workouts. They absorb impact and reduce strain on the body. This feature promotes safety and comfort during intense training sessions.

Healthcare Applications

Hospitals and care facilities use high-density open cell foam in medical seating and bedding. The foam helps prevent pressure ulcers in patients who are bedridden for long periods. It evenly distributes body weight. Thus, minimizing pressure on vulnerable areas. This promotes patient comfort and aids in injury prevention.

When buying high-density foam sheets for resale, buyers should keep in mind the following factors to ensure they get varieties that will sell well, based on different customers’ needs.

Density rating

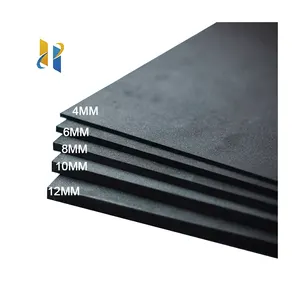

Buyers should consider the density of the foams as it determines the level of support a foam mattress provides. They should get options with high-density ratings, over five pounds as softer foams that have a lower density are ideal for short use only. At the same time, they should get low-density foams. These are softer and more comfortable, suitable for people who prefer soft and cushy seats.

Customizations

Buyers should look for manufacturers who offer customized foams. Depending on the intended uses, buyers may choose materials of different firmness levels, thicknesses, and densities. They should also get foams in various shapes to cater to different requirements, especially if they intend to serve specialized markets.

Types

Buyers should choose memory foams with open-cell and closed-cell structures to serve different needs. Open-cell memory foam has a porous structure, contributing to breathability and air permeability. This makes it an ideal option for people with respiratory conditions. Closed-cell memory foam has a denser structure that offers firm support. This type of foam acts as a strong cushion for heavy items and provides excellent insulation.

Test

Buyers should prioritize quality over cost. They should test different options by sitting on them. If the business will be catering to specialized markets such as medical use, buyers should consider special options like egg crate foam that helps prevent bed sores.

Interactive foams

Although many businesses use high-density memory foam, tablet buyers cater to customers who use specialized and interactive products. Memory foam is known for its conforming capacity as it contours to the user's shape. This feature gives the person the required support. In contrast, traditional foam cannot be molded and thus provides less effective support.

Firmness

Buyers should get high-density memory foams in various firmness levels as it helps customers select the option that meets their needs. They should target the most favored firmness levels, which normally range between three and eight. The firmness levels depend on the weight of the person using the foam. The firmness level is also influenced by the position they prefer when sleeping.

Support and comfort

Buyers should seek high-density memory foam that provides great support and comfort. They should choose memory foam with a high indentation load deflection. This will ensure that the foam will not compress even with heavy loads. Also, when the body sinks into memory foam, it means less pressure is exerted on the body's pressure points, providing comfort.

High-density foam refers to cushioning foams that are used to offer support to people or heavy items. High-density foam is made of viscoelastic polymeric substance cellular blocks of flexible polyurethane foam. These viscoelastic polymers rearrange their molecular structure according to the pressure exerted on foam. Once the pressure is released, the polymer returns to its original state.

High-density foam comes with numerous benefits. These include:

When buying high-density foam for resale online, buyers should consider the seller's reputation to ensure they get quality products. They should also get the options in various densities, firmness levels, and qualities to cater to different customers' requirements. Since the target market is mainly business buyers, buyers should get foams that are suitable for various purposes such as medical use, head cushions, insulation, and buoyancy. Before placing bulk orders, buyers should start by ordering samples and testing them.

Polyurethane foam has a close stoic structure and thus is difficult for air and moisture to pass through. This makes it ideal for insulation applications. Unfortunately, the foam is not fire resilient. However, some manufacturers add special chemicals to increase its fire resistance.