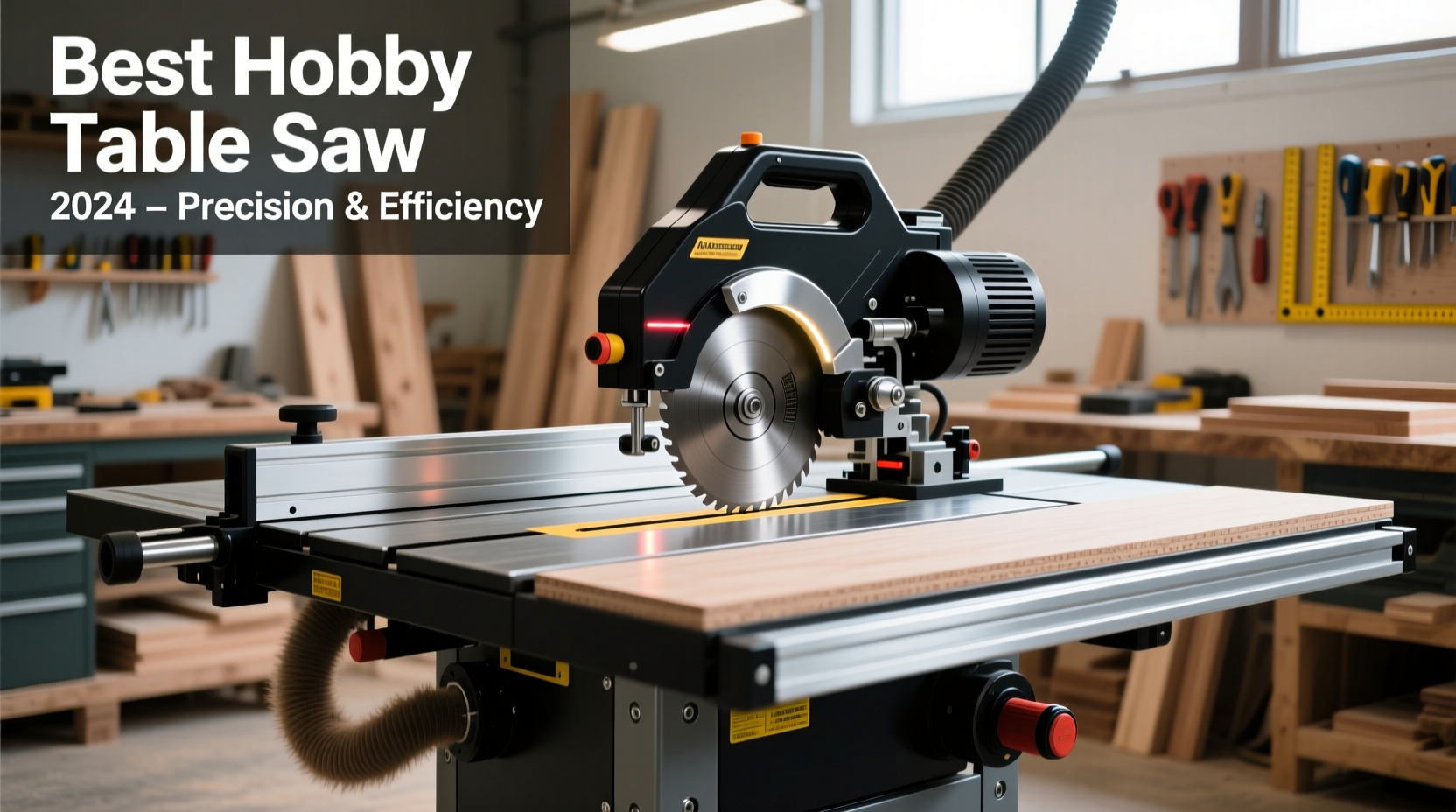

For woodworkers who operate in a home shop or garage, precision and efficiency are not luxuries—they’re necessities. Whether you're building fine furniture, crafting cabinetry, or creating intricate joinery, your tools must deliver accuracy, consistency, and safety. At the heart of most serious hobbyist workshops is the table saw, a machine that defines what’s possible in terms of cut quality and workflow speed. But not all table saws are created equal. For hobbyists balancing budget, space, and performance, selecting the right model can make the difference between frustration and fulfillment.

The best hobby table saw strikes a balance between power, accuracy, durability, and ease of use—without requiring industrial-level space or investment. This guide examines top contenders, key features to prioritize, and practical advice from experienced woodworkers to help you choose the ideal saw for your needs.

What Defines a Great Hobby Table Saw?

A hobbyist table saw isn’t just a smaller version of a contractor or cabinet saw—it’s engineered for a different kind of user. The ideal model should offer:

- Precision alignment: Fence systems and miter gauges that stay true over time.

- Sufficient power: A motor strong enough to handle hardwoods without bogging down.

- Compact footprint: Fits comfortably in a garage or basement workshop.

- User-friendly safety features: Blade guards, riving knives, and easy access to controls.

- Dust collection compatibility: Minimizes cleanup and improves air quality.

- Stability: Minimal vibration during operation ensures cleaner cuts.

Top Contenders: Comparing Leading Hobby Table Saws

After evaluating dozens of models based on performance, build quality, and user feedback, five stand out as exceptional choices for hobby woodworkers.

| Model | Horsepower | Fence Type | Dust Collection | Price Range | Best For |

|---|---|---|---|---|---|

| DEWALT DWE7491RS | 15 Amp | Rack-and-pinion | Yes (3.5” port) | $400–$500 | Mobility & accuracy |

| Bosch REAXX JS1000A | 15 Amp (with Auto-Stop) | XT-ACT Adjust | Yes (integrated) | $800–$900 | Safety-focused users |

| SKIL TS6307-00 | 15 Amp | Steel-reinforced | Limited (2.5”) | $250–$300 | Budget-conscious beginners |

| Hitachi C10RJL (Now Metabo HPT) | 15 Amp | Sliding rail | Yes (3.25”) | $500–$600 | Crosscutting accuracy |

| RIDGID R4512 | 15 Amp | Cast aluminum fence | Yes (3.5”) | $500–$600 | All-around performance |

The DEWALT DWE7491RS consistently ranks high among weekend warriors for its excellent fence system and wheeled stand, making it both accurate and portable. Meanwhile, the Bosch REAXX introduces an innovative retraction system that pulls the blade below the table in milliseconds upon contact—a game-changer for injury prevention.

“Even at the hobby level, investing in a reliable fence system pays off immediately in joint quality and reduced material waste.” — Mark Thompson, Woodworking Instructor & Cabinetmaker

Key Features That Matter Most

When comparing models, don’t get distracted by flashy extras. Focus instead on components that directly affect performance.

Fence System Accuracy and Durability

The fence is arguably the most critical component after the blade itself. A poorly aligned or flimsy fence leads to inconsistent rip cuts, binding, and dangerous kickback. Look for fully adjustable, dual-point locking fences like those found on the RIDGID R4512 or DEWALT models. These allow micro-adjustments and remain rigid under pressure.

Blade Quality and Arbor Runout

Many entry-level saws come with low-grade blades that tear rather than cut cleanly. Plan to upgrade to a premium combination or crosscut blade (e.g., Forrest, Freud, or Diablo) within your first few projects. Also, test arbor runout—if it exceeds 0.003”, expect vibration and poor cut quality.

Dust Extraction Efficiency

A powerful dust port connected to a shop vacuum or cyclone system keeps your workspace clean and reduces respiratory risks. Models like the Bosch REAXX include internal shrouds that capture over 90% of fine particles, a major advantage for indoor shops.

Real-World Example: Building a Workbench with the DEWALT DWE7491RS

Tom Reynolds, a mechanical engineer and weekend woodworker from Portland, recently built a 4’ x 8’ Roubo-style bench using only his DEWALT DWE7491RS and hand tools. Despite working in a 12x14 ft garage, he achieved consistent 3/4” rip cuts across 12-ft Douglas fir beams.

“I was skeptical about a jobsite saw handling thick stock,” Tom said. “But with sharp blades and slow feed rates, it powered through. The rack-and-pinion fence never drifted more than 1/64” over 30 feet of cumulative cutting. I saved $600 compared to a cabinet saw and gained mobility when I need to store it.”

His experience underscores a growing trend: modern hobby saws, when paired with good technique, can rival larger, heavier machines in real-world output.

Step-by-Step Guide to Setting Up Your Hobby Table Saw

Proper setup is essential for long-term accuracy and safety. Follow this sequence when installing or tuning your saw:

- Level the saw: Place it on a stable surface and use a machinist’s level to ensure the tabletop is flat in all directions.

- Align the blade to the miter slot: Use a dial indicator or precision square to set the blade parallel within 0.002”.

- Calibrate the fence: Lock it at 24” from the blade and measure front and back distances. Adjust until identical.

- Test the riving knife: Ensure it aligns with the blade and moves up/down with the blade assembly.

- Install a zero-clearance insert: Reduces splintering and supports small workpieces.

- Connect dust extraction: Seal all gaps with foil tape if necessary to maximize suction.

- Run a test cut: Use scrap plywood to evaluate smoothness and squareness.

Checklist: Before You Buy a Hobby Table Saw

- ✅ Measure available space including clearance for full sheet goods

- ✅ Confirm motor amps (15A minimum for hardwoods)

- ✅ Inspect fence rigidity and adjustability

- ✅ Verify dust port size (3.5” preferred)

- ✅ Test blade elevation and tilt mechanisms for smoothness

- ✅ Check warranty and local service support

- ✅ Read recent owner reviews focusing on long-term reliability

Frequently Asked Questions

Can a hobby table saw handle hardwoods like oak or maple?

Yes, provided it has a 15-amp motor and a sharp blade. Feed the wood steadily but slowly, avoiding forcing the cut. Pre-cutting oversized stock into manageable widths also helps reduce strain.

Is a sliding table saw worth it for hobbyists?

Sliding saws offer superior crosscut accuracy but are typically more expensive and require more space. For most hobbyists, a high-quality miter gauge or crosscut sled delivers similar results at lower cost.

How often should I maintain my table saw?

Perform basic cleaning after every 5–10 uses. Lubricate elevation gears every six months and recheck alignment quarterly. Replace belts or damaged parts immediately.

Final Thoughts: Choosing Confidence Over Compromise

The best hobby table saw doesn’t have to be the largest or most expensive—but it should inspire confidence every time you power it on. Precision begins with stability, clarity, and control. Whether you choose the value-packed SKIL model for learning fundamentals or invest in the safety-forward Bosch REAXX, your decision should reflect how you work, what you build, and how seriously you take craftsmanship.

Woodworking is as much about process as it is about product. With the right saw, even modest spaces become studios of possibility. Choose wisely, set it up meticulously, and let every cut bring you closer to mastery.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?