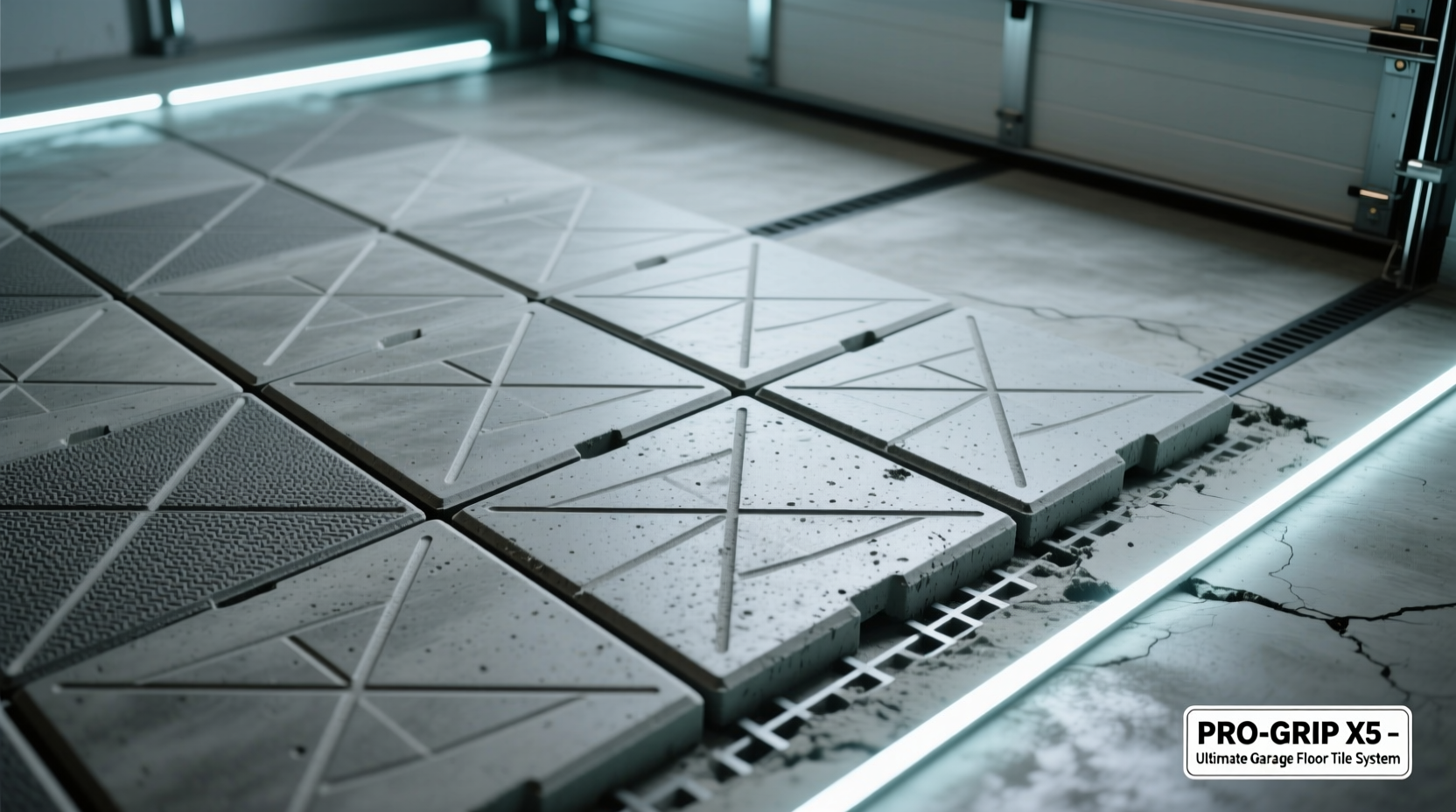

A garage is more than just a parking space—it's a workshop, storage area, and sometimes even a gym or hobby room. With such varied demands, your garage floor must be tough, low-maintenance, and visually appealing. Choosing the right flooring can dramatically improve functionality and durability. Among the top contenders, interlocking tiles stand out as one of the most practical solutions for homeowners seeking long-term value without complex installation.

Why Garage Floor Material Matters

The garage floor endures extreme conditions: temperature swings, oil spills, heavy vehicle traffic, and dropped tools. Concrete, while common, cracks over time and stains easily. A superior flooring solution should resist these challenges while offering comfort underfoot and aesthetic improvement.

Durability, ease of installation, moisture resistance, and slip safety are critical factors. The best garage floor tiles combine industrial-grade resilience with DIY-friendly design—allowing homeowners to upgrade their space in a weekend without professional help.

Top 5 Durable & Easy-to-Install Garage Flooring Options

Not all garage tiles are created equal. Here’s a breakdown of the most reliable types available today, evaluated on strength, installation speed, cost, and longevity.

- Polypropylene Interlocking Tiles – Impact-resistant, UV-stable, and ideal for high-traffic areas.

- EPDM Rubber Tiles – Excellent shock absorption and noise reduction; great for home gyms.

- PVC Modular Tiles – Budget-friendly and water-resistant but less rigid under heavy loads.

- Epoxy-Coated Concrete – Seamless finish with chemical resistance, though requires surface prep and curing time.

- Urethane Hybrid Tiles – Premium blend offering flexibility, thermal stability, and industrial toughness.

Among these, polypropylene and urethane hybrid tiles consistently rank highest for overall performance in independent durability tests.

Comparing Key Features: Garage Tile Showdown

| Material | Installation Time | Load Capacity | Water Resistance | Lifespan |

|---|---|---|---|---|

| Polypropylene | 2–4 hours | High (up to 10,000 psi) | Excellent | 15+ years |

| EPDM Rubber | 3–5 hours | Moderate | Very Good | 10–12 years |

| PVC | 2–3 hours | Low-Moderate | Good | 5–8 years |

| Epoxy Coating | 2–3 days (incl. cure) | High | Excellent | 7–10 years |

| Urethane Hybrid | 3–4 hours | Very High | Excellent | 15–20 years |

While epoxy provides a sleek, seamless look, its multi-day installation and sensitivity to improper application make it less beginner-friendly. In contrast, modular tiles offer immediate results and future adaptability.

Step-by-Step: Installing Interlocking Garage Floor Tiles

One of the biggest advantages of modern garage tiles is their tool-free, snap-together design. Follow this sequence for a flawless result:

- Clear and Clean the Floor – Remove all items, sweep debris, and degrease oily spots using trisodium phosphate (TSP) or a concrete cleaner.

- Inspect for Damage – Repair major cracks or uneven surfaces. Small imperfections are acceptable due to tile flexibility.

- Start from the Front Corner – Begin near the garage door, placing the first tile flush against both walls.

- Connect Subsequent Tiles – Press edges together firmly until they lock. Use a rubber mallet if needed.

- Cut Edge Tiles as Needed – Measure and mark tiles for walls or obstructions. Score with a utility knife and snap or cut with a jigsaw.

- Install Edge Trims (Optional) – Secure perimeter pieces for a finished look and added safety.

- Wait 24 Hours Before Heavy Use – Allows slight expansion to stabilize in place.

No adhesives or grouting required. If reconfiguration is ever needed—say, for plumbing access—you can lift sections and reinstall them later.

“Modular tiles have revolutionized residential garage upgrades. Their resilience under fluctuating temperatures and minimal maintenance needs make them the smart choice for most homeowners.” — James Rutherford, Industrial Flooring Consultant

Real-World Example: Transforming a 2-Car Garage in One Weekend

Mark T., a homeowner in Colorado, replaced his cracked, stained concrete garage floor with black-and-gray polypropylene tiles. His garage sees frequent use: two vehicles, power tools, and seasonal gear storage. After cleaning the slab and letting it dry for 48 hours, he laid 36 square meters of 1” thick interlocking tiles over two days with help from his son.

The result? A clean, modern-looking floor that resists oil drips and doesn’t show tire marks. He noted improved lighting reflection and no cold radiating through work boots during winter projects. When a shelf collapsed and scratched one tile, he simply popped it out and replaced it—a repair that took five minutes.

“I’ve spent less time maintaining this floor than I did scrubbing the old concrete,” Mark said. “And it looks like a pro job.”

Expert Tips for Maximizing Longevity

- Vacuum or sweep monthly to prevent grit buildup that can scratch tile surfaces.

- Use a mild detergent and hose down annually for deep cleaning.

- Avoid dragging sharp metal objects directly across the surface.

- Check edge connectors every year to ensure no loosening has occurred.

- Store chemicals in sealed containers on shelves, not directly on the floor.

Common Mistakes to Avoid

Even simple installations can go wrong without attention to detail. These pitfalls undermine performance and appearance:

- Skipping floor prep – Dust, oil, or moisture trapped beneath tiles causes warping or odor.

- Starting in the wrong spot – Begin at the most visible corner to maintain symmetry.

- Forcing misaligned tiles – This stresses connectors and leads to premature failure.

- Ignoring expansion gaps – Especially important in climates with wide temperature swings.

- Using cheap, thin tiles – Often lack structural support and wear quickly under vehicles.

Frequently Asked Questions

Can I install garage tiles over existing cracks in concrete?

Yes, as long as the cracks are stable and not actively expanding. Most interlocking tiles span minor imperfections due to their rigidity and floating design. For large cracks, fill with a concrete patching compound first.

Are garage floor tiles safe for jack stands or lifts?

High-density polypropylene and urethane hybrid tiles can safely support jack stands when used with load-distributing pads. However, avoid permanent hydraulic lifts unless anchored into the concrete below the tiles.

Do interlocking tiles emit fumes in hot garages?

Quality tiles made from non-toxic, UV-stabilized polymers do not off-gas under normal conditions. Look for certifications like ASTM F963 or REACH compliance to ensure safety.

Final Checklist Before You Buy

Use this quick guide to select the best product for your needs:

- ✅ Confirmed UV resistance (for garages with sun exposure)

- ✅ Minimum thickness of 3/8” (10 mm) for vehicle support

- ✅ Interlock mechanism with tight tolerance (no wobbling)

- ✅ Chemical and oil resistance rating

- ✅ Warranty of at least 10 years

- ✅ Available edge trim and ramp pieces

- ✅ Made by a reputable brand with customer support

Conclusion: Upgrade Your Garage Floor with Confidence

The best tile for garage floor isn't just about durability—it's about transforming an overlooked space into one that’s functional, attractive, and built to last. With today’s advanced materials, you no longer need to choose between strength and simplicity. Interlocking polypropylene and urethane hybrid systems deliver both, empowering DIYers to achieve professional-grade results in hours.

Whether you're protecting tools, storing seasonal gear, or building a workshop, investing in a high-performance garage floor pays off in comfort, cleanliness, and long-term savings. Evaluate your usage patterns, climate, and budget, then take the next step: measure your space, order samples, and begin your upgrade.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?