When a problem arises in any process—be it on the factory floor, in software development, or during customer service delivery—the immediate reaction is often to fix the symptoms. But without addressing the underlying cause, the same issue tends to recur. The Five Whys Root Cause Analysis is a powerful yet simple technique developed to drill past surface-level symptoms and uncover the true origin of a problem. Originally pioneered by Toyota in their production system, this method has since been adopted across industries as a cornerstone of continuous improvement.

The strength of the Five Whys lies in its simplicity. It doesn’t require complex data analysis or statistical tools. Instead, it relies on structured questioning to peel back layers of causation. When applied correctly, it can transform reactive firefighting into proactive problem prevention.

What Is the Five Whys Technique?

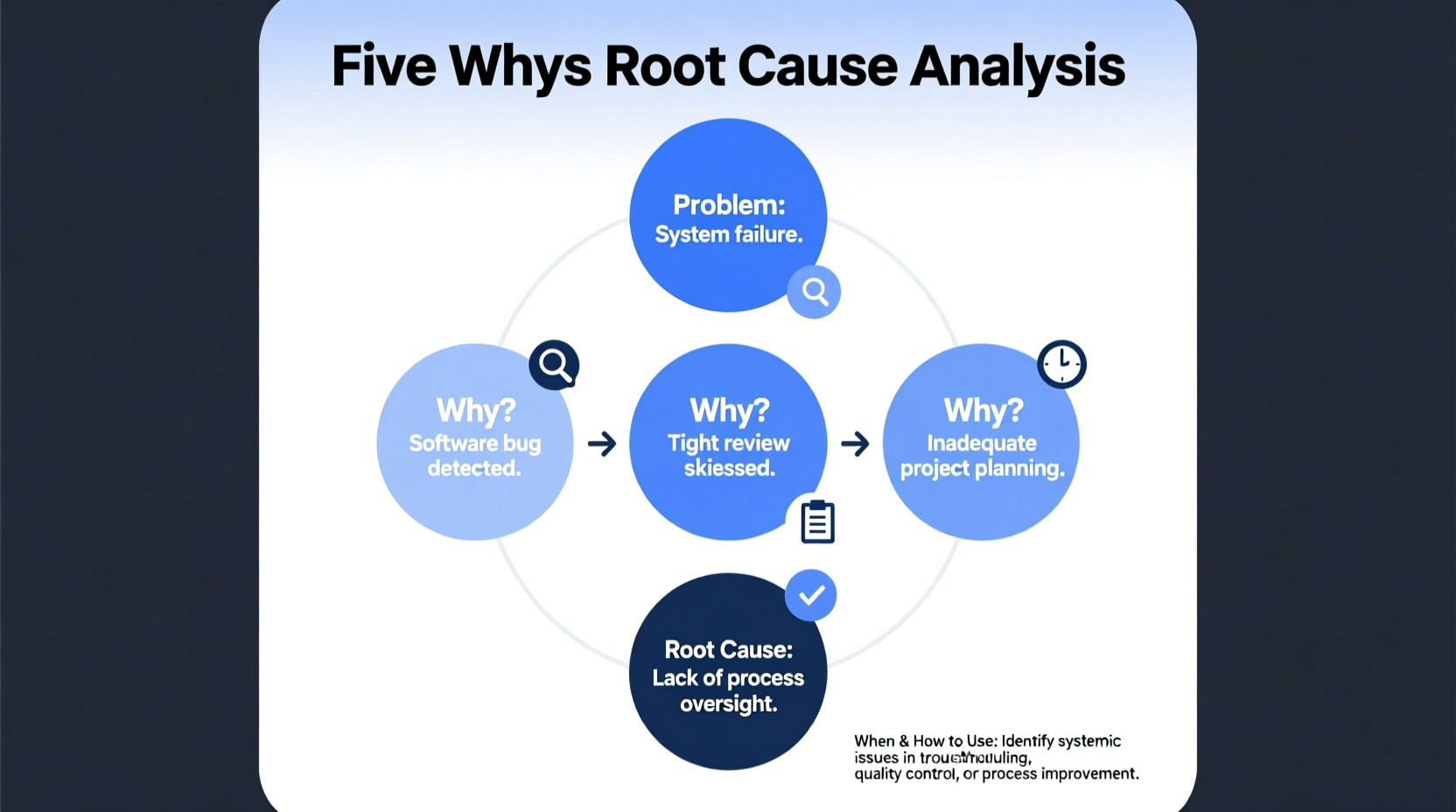

The Five Whys is an iterative interrogative method used to explore the cause-and-effect relationships underlying a particular problem. The primary goal is to determine the root cause of a defect or failure by repeatedly asking, “Why?” Each answer forms the basis of the next question. The “five” in the name is not prescriptive—it’s typical to ask why five times, but some problems may require fewer or more iterations to reach the core issue.

For example:

- Problem: The machine stopped working.

- Why? Because the circuit overloaded.

- Why? Because there wasn’t enough lubrication.

- Why? Because the lubrication pump was malfunctioning.

- Why? Because the pump’s shaft was worn out.

- Why? Because metal shavings clogged the filter—maintenance checks were skipped last month.

The final answer reveals a procedural breakdown in maintenance scheduling—a systemic issue rather than a one-off mechanical failure. This insight allows organizations to implement preventive measures, such as updating maintenance protocols, rather than simply replacing parts.

When to Use the Five Whys

The Five Whys is most effective in situations where problems are moderately complex but not so technically intricate that they demand advanced analytical tools like fault tree analysis or Six Sigma methodologies. It works best when:

- A team observes a clear, tangible problem with a known starting point.

- The issue involves human processes or interactions (e.g., delays, errors, miscommunication).

- There is direct access to the process or environment where the failure occurred.

- The team has members with firsthand knowledge of the workflow.

Common applications include:

- Manufacturing line stoppages

- Software bug recurrence

- Customer complaint patterns

- Project timeline overruns

- Safety incidents

It is less suitable for highly technical engineering failures involving multiple independent variables or when deep statistical validation is required. In such cases, combining the Five Whys with other root cause analysis tools enhances accuracy.

How to Conduct a Five Whys Analysis: Step-by-Step

Conducting an effective Five Whys session requires preparation, focus, and collaboration. Follow this structured approach to maximize results:

- Gather the Right Team: Include individuals directly involved in the process. Their practical insights are invaluable.

- Define the Problem Clearly: Write a concise statement describing the issue. Avoid vague terms like “poor performance.” Instead, say “Order fulfillment delayed by 48 hours on June 10.”

- Ask 'Why?' Repeatedly: Begin with the problem and ask why it occurred. Use each answer to form the next question. Keep responses fact-based and grounded in evidence.

- Identify the Root Cause: Stop when further questioning no longer yields meaningful answers or reveals a process gap that can be addressed.

- Develop Corrective Actions: For the identified root cause, define specific, actionable steps to prevent recurrence.

- Implement and Monitor: Assign ownership of solutions and track effectiveness over time.

“Toyota’s philosophy is to go see, understand the situation, ask why five times, and take action based on facts, not assumptions.” — Taiichi Ohno, Father of the Toyota Production System

Real-World Example: Hospital Medication Error

A nurse administered the wrong dosage of medication to a patient. An investigation using the Five Whys revealed:

- Why? The nurse pulled the incorrect vial from storage.

- Why? The vials were stored side by side with similar labels.

- Why? The pharmacy had repackaged medications without color-coding high-risk drugs.

- Why? There was no standardized labeling protocol for repackaged items.

- Why? Staff training on safe medication handling hadn’t been updated in two years.

The root cause was outdated training and lack of standardization—not individual negligence. As a result, the hospital revised its safety training, introduced color-coded bins, and implemented monthly audits. Medication errors dropped by 78% over the next quarter.

Best Practices and Common Pitfalls

To ensure your Five Whys sessions lead to real improvements, follow these guidelines:

| Do’s | Don’ts |

|---|---|

| Base answers on observation and data | Accept guesses or assumptions as answers |

| Involve frontline staff in the analysis | Let managers dictate the cause without input |

| Stop when a systemic flaw is uncovered | Stop at the first convenient answer |

| Document findings and actions taken | Fail to follow up on corrective measures |

| Use visuals like flowcharts to map the chain | Allow the discussion to become unfocused |

Checklist: Running an Effective Five Whys Session

- ✅ Define the problem in writing with specific details (who, what, when, where)

- ✅ Assemble a cross-functional team familiar with the process

- ✅ Start with the symptom and ask “Why?” aloud for each layer

- ✅ Write down each answer clearly before moving to the next “Why?”

- ✅ Verify answers with evidence, not opinion

- ✅ Identify the root cause when further questioning adds no value

- ✅ Assign corrective actions with deadlines and owners

- ✅ Schedule a review to confirm the solution worked

Frequently Asked Questions

Can the Five Whys be used alone, or should it be combined with other tools?

The Five Whys is effective for straightforward issues, especially those involving human or process factors. However, for complex problems with multiple contributing causes, it’s best combined with tools like fishbone diagrams (Ishikawa), Pareto charts, or Failure Mode and Effects Analysis (FMEA). These help structure broader inputs before narrowing down with the Five Whys.

What if we reach different root causes with different teams?

Variations can occur if teams lack complete information or interpret answers subjectively. To reduce inconsistency, ground each “why” in verifiable facts. Record observations, timelines, and witness statements. Facilitate sessions with a neutral moderator to maintain objectivity.

Is five the exact number of questions needed?

No. Some problems resolve in three whys; others may take seven or more. The key is to continue until you reach a process or system weakness that can be improved. If the answer leads to a controllable action, you’ve likely found the root cause.

Conclusion: Turn Problems into Progress

The Five Whys Root Cause Analysis is more than a troubleshooting tool—it’s a mindset shift from reaction to prevention. By consistently asking “why,” teams move beyond temporary fixes and begin building resilient systems. Whether in healthcare, IT, logistics, or customer service, the ability to uncover true causes separates high-performing organizations from those stuck in cycles of repetition.

Mastery comes not from perfecting the method, but from practicing it regularly. Start small: apply the Five Whys to your next minor setback. Document the process. Share insights. Over time, this habit transforms organizational culture—one question at a time.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?