Static decorations have their place—clean lines, intentional stillness, minimalist appeal. But when a pine bough sways almost imperceptibly in a draft, or a paper crane tilts gently as if breathing, something shifts: the object stops being *decor* and starts feeling *alive*. That’s the power of subtle motion—not spectacle, but suggestion. Silent mini servo motors make this possible without compromising serenity. Unlike traditional servos that whine, chatter, or vibrate audibly, modern ultra-quiet variants (often rated below 25 dB at 30 cm) deliver micro-movements so refined they feel organic: a slow 3° tilt of a ceramic owl’s head, a 7-second arc of a suspended origami bird’s wing, a barely-there rotation of a brass compass rose on a mantel. This isn’t robotics for showrooms—it’s hushed kinetic craft for homes, galleries, retail displays, and seasonal installations where atmosphere matters more than mechanics.

Why “silent” matters—and what makes a servo truly quiet

Most hobby-grade servos produce audible noise from three sources: gear meshing (plastic or metal gears grinding), motor coil hum (especially under PWM control), and mechanical resonance (vibrations transmitted through mounting surfaces). “Silent” here doesn’t mean zero sound—it means operation that blends into ambient room noise: quieter than a refrigerator’s idle hum, softer than turning a page. True silence begins with design choices, not marketing labels.

Key engineering features that reduce noise:

- Coreless DC motors: Eliminate iron-core cogging, reducing torque ripple and high-frequency whine.

- Planetary or harmonic drive gearing: Distribute load across multiple contact points, minimizing gear slap and backlash.

- Integrated soft-start/soft-stop firmware: Prevents abrupt acceleration/deceleration that causes “thunk” or “clack” at motion endpoints.

- Low-noise potentiometers or magnetic encoders: Replace noisy mechanical wipers with contactless position sensing.

Not all “mini” servos qualify. A standard SG90 may draw attention with its buzz; a Power HD PDI-6221MG or FEETECH FS90R (with metal gears and optimized control ICs) operates at 22–24 dB—close to library-level quiet. Always verify decibel ratings in datasheets, not product titles.

Selecting the right servo for your decoration type

Choosing hinges on torque, size, speed, and mounting compatibility—not just silence. Overpowering creates unnecessary strain and noise; underpowering leads to stalling, heat buildup, and erratic movement. Below is a practical decision framework based on common decorative applications:

| Decoration Type | Recommended Servo Model Range | Max Torque (kg·cm) | Key Mounting Consideration |

|---|---|---|---|

| Paper or thin fabric ornaments (e.g., hanging snowflakes, layered doves) | FS90R, MG90S (micro) | 1.6–1.8 | Use laser-cut acrylic brackets to isolate vibration; avoid direct glue-to-paper attachment |

| Wood or ceramic figurines (e.g., rotating forest animals, nodding owls) | PDI-6221MG, TowerPro MG996R (standard size) | 6.5–10 | Mount inside hollow bases using rubber grommets to dampen transmission |

| Glass or mirrored elements (e.g., floating crystal mobiles, pivoting mirror tiles) | HiTec HS-422 (low-vibration analog) | 2.2 | Pair with ball-bearing pivot pins—never rely on servo horn alone for rotational stability |

| Textile-based installations (e.g., kinetic textile wall hangings, fluttering silk leaves) | Power HD 1501MG (high-torque micro) | 4.2 | Integrate servo behind backing board; use monofilament line routed through concealed channels |

Note: Torque requirements assume clean mechanical advantage. A 1.8 kg·cm servo can move a 300g paper ornament easily—but only if the pivot point is aligned and friction is minimized. Always prototype with temporary mounts first.

A real-world example: The whispering willow branch

In early December 2023, interior designer Lena Ruiz installed a kinetic centerpiece for a boutique hotel lobby in Portland: a 1.2-meter dried willow branch suspended horizontally above a marble console. Guests expected stillness—what they experienced was quiet aliveness. Every 90 seconds, the branch tilted 4.2° downward on its left side, held for 3 seconds, then returned—like a slow, deep breath.

Lena used two FS90R servos mounted inside a custom walnut cradle, each driving a 3D-printed cam that pressed against a low-friction Delrin bearing embedded in the branch’s base. She avoided gears or belts entirely—relying instead on direct cam-pressure motion. Power came from a hidden 5V/2A regulated supply, and timing was managed by an ESP32 programmed with randomized intervals (±12 seconds) to prevent rhythmic predictability. No wiring was visible: silicone-coated 30 AWG magnet wire ran through hollow dowels, soldered to gold-plated pogo pins for serviceability.

Guest feedback was telling: “I kept thinking there was a draft,” said one reviewer. “It felt like the room was breathing.” That’s the benchmark—not “cool tech,” but undetectable intentionality.

“Subtlety in motion isn’t about limiting range—it’s about honoring the viewer’s subconscious. When movement feels unforced and unhurried, it bypasses scrutiny and lands directly in the limbic system.” — Dr. Aris Thorne, Kinetic Design Researcher, MIT Media Lab

Step-by-step: Building a silent-motion pinecone pendant

This hands-on project demonstrates core principles—low-noise actuation, vibration isolation, and invisible integration—in under 90 minutes. It yields a 75mm-diameter pinecone that rotates slowly (one full turn every 4.5 minutes), powered by a single micro-servo.

- Gather materials: FS90R servo, 3D-printed servo mount (STL file available via GitHub link), 2mm brass rod (120 mm), pinecone (dried, hollowed core), matte black spray paint, rubber O-rings (3mm ID), 5V regulated USB power bank, micro-USB cable, fine sandpaper, epoxy putty.

- Prepare the pinecone: Drill a 2.2mm axial hole through the center, top to bottom. Lightly sand interior to remove debris. Spray-paint exterior matte black—this reduces glare during rotation and visually minimizes hardware.

- Build the drive shaft: Insert brass rod through pinecone. Secure with epoxy putty at top and bottom, leaving 10mm protruding above and 15mm below. Let cure fully (2 hours minimum).

- Mount the servo silently: Attach servo to 3D-printed mount using rubber O-rings instead of screws—this decouples vibration. Glue mount to underside of ceiling panel or shelf bracket using vibration-dampening adhesive (e.g., 3M VHB tape + silicone sealant bead).

- Connect & calibrate: Use a servo tester or Arduino sketch to set neutral position (0°) so the pinecone hangs perfectly vertical. Then program a 0.05°/second sweep over 4.5 minutes—no abrupt stops. Confirm motion is smooth and silent at all angles.

- Conceal and finalize: Wrap exposed brass rod below pinecone with black velvet cord. Route USB cable behind trim. Test for 24 hours to ensure thermal stability—servos should remain cool to touch.

Five critical mistakes—and how to avoid them

Even with quality components, execution flaws undermine silence and longevity. These are the most frequent pitfalls observed in professional installations:

- Mistake #1: Relying on servo horns for structural support → Solution: Use the horn only for initial positioning. Transfer load to a rigid axle, pivot pin, or bearing assembly. Horn plastic flexes and transmits resonance.

- Mistake #2: Powering servos directly from Arduino 5V pins → Solution: Use an external regulated 5V supply (≥2A) with separate ground return. Voltage sag causes jitter and audible stutter.

- Mistake #3: Ignoring thermal mass in enclosures → Solution: If embedding in wood or plaster, leave ≥3mm air gap around servo body. Heat buildup accelerates gear wear and increases coil resistance noise.

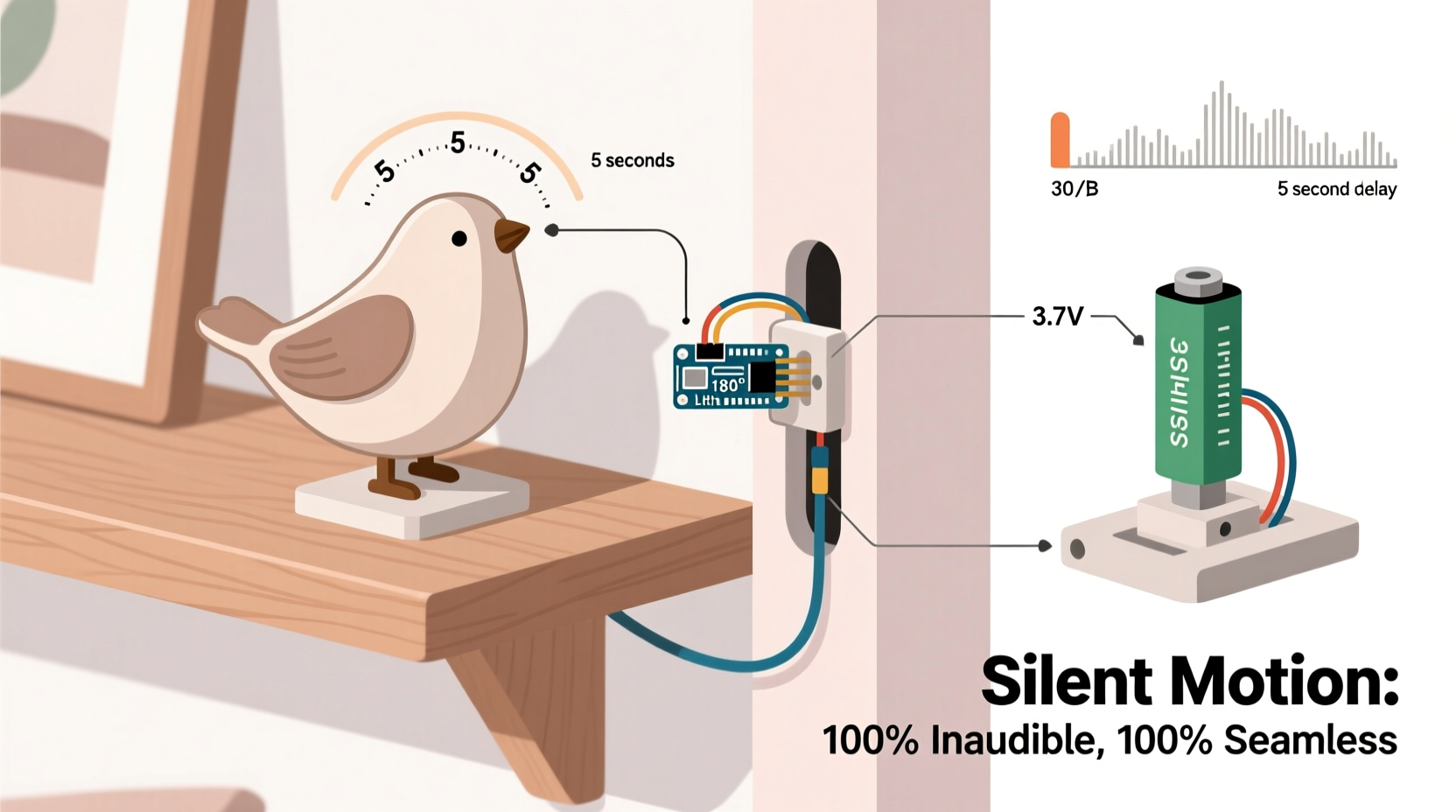

- Mistake #4: Using full 180° sweeps unnecessarily → Solution: Restrict motion to 10–30° arcs unless required. Smaller ranges reduce gear stress, lower current draw, and minimize endpoint “thump.”

- Mistake #5: Skipping positional calibration → Solution: Always run a calibration routine at startup (e.g., move to known home position using limit switch or optical sensor) rather than assuming 0° = neutral. Drift accumulates.

FAQ: Practical questions from makers and decorators

Can I run multiple silent servos from one power supply?

Yes—but calculate total current draw conservatively. An FS90R draws ~100 mA idle and up to 650 mA under load. For five units, budget ≥4A continuous capacity. Use star-wiring (individual leads back to supply) instead of daisy-chaining to prevent voltage drop and crosstalk noise.

How do I hide wiring in a wooden mantelpiece without drilling visible holes?

Drill shallow, 2mm-wide kerfs (≤3mm deep) along existing grain lines using a jeweler’s saw or Dremel with cutoff wheel. Route 30 AWG enameled wire into kerf, then fill with tinted wood filler matching the grain. Sand flush. The seam disappears visually and acoustically—no rattling in grooves.

Will humidity affect performance in seasonal displays?

Yes—especially for paper, fabric, or untreated wood. Humidity changes cause material swelling/shrinking, increasing friction on pivots. Mitigate by sealing moving joints with dry-film lubricant (e.g., DuPont Teflon Dry-Film), not oil or grease, which attracts dust and hardens over time.

Conclusion: Motion as mindful detail

Adding motion to static objects isn’t about novelty—it’s about deepening presence. A silent servo doesn’t shout “look at me”; it invites pause, reflection, and quiet recognition. That pinecone doesn’t spin to impress. It turns because turning is part of its nature now—gentle, inevitable, unhurried. The same applies to your mantel, your gallery wall, your holiday table. You don’t need complex coding or industrial parts. You need intention, careful listening (to both sound and silence), and respect for materials. Start small: choose one decoration you love but rarely notice. Give it breath. Give it rhythm. Give it the dignity of quiet life.

Then step back—not to admire the mechanism, but to witness how the room changes when stillness learns to sigh.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?