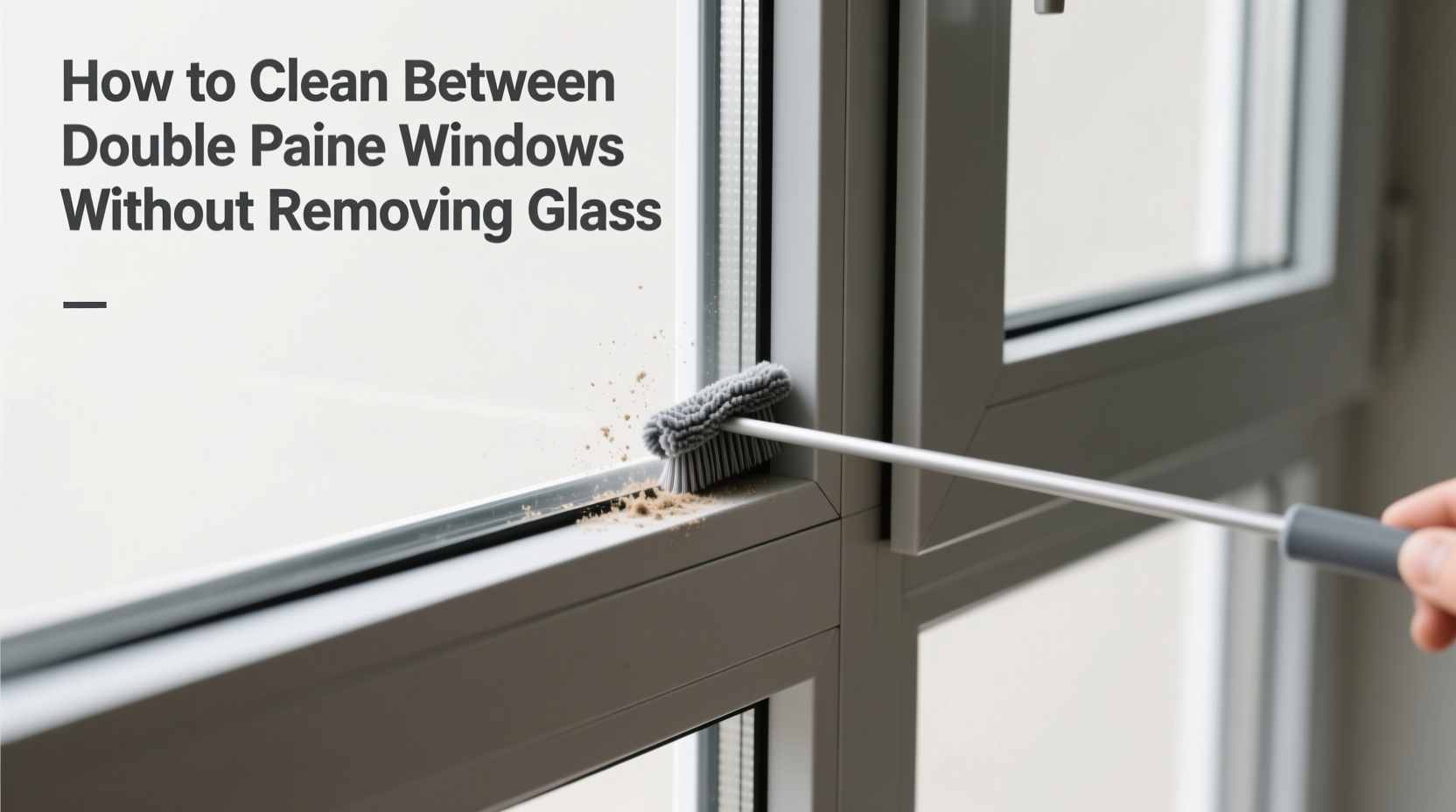

Double pane windows are a staple in modern homes, offering superior insulation, noise reduction, and energy efficiency. However, when moisture or dirt accumulates between the two panes, it can create foggy patches, streaks, or even mold—diminishing both visibility and aesthetic appeal. The common misconception is that once contamination occurs inside the sealed unit, replacement is the only option. That’s not always true. With the right techniques, it’s possible to clean between double pane windows without removing the glass, restoring clarity and extending the life of your windows.

This guide walks through practical, non-invasive methods backed by window restoration professionals, detailing tools, step-by-step procedures, and long-term maintenance strategies to keep your windows clear and functional for years.

Understanding Double Pane Window Structure

Before attempting any cleaning method, it's essential to understand how double pane (or insulated) glass units work. These windows consist of two panes of glass separated by a spacer, creating an air or gas-filled gap—typically argon or krypton—that enhances thermal performance. The edges are sealed with butyl or silicone-based sealants to prevent moisture and air from entering.

Over time, exposure to temperature fluctuations, UV radiation, and poor installation can cause the seal to degrade. Once compromised, humid air infiltrates the space between the panes, leading to condensation, mineral deposits, and sometimes microbial growth. This internal fogging is often mistaken for permanent damage, prompting unnecessary replacements.

“Many homeowners assume fogged windows must be replaced, but seal repair and venting methods can restore clarity in over 70% of cases.” — Daniel Reeves, Window Restoration Specialist, National Glass Preservation Society

Can You Really Clean Between the Panes?

The short answer: yes—but with conditions. If the seal has failed and moisture has entered, you’re not cleaning a vacuum-sealed chamber. Instead, you're accessing the inter-pane space through micro-drilling or venting techniques designed to extract contaminants and re-establish airflow.

These methods do not require removing the entire window unit from the frame, preserving structural integrity and avoiding costly labor. While they won’t work on severely damaged or cracked units, they are highly effective for windows with minor to moderate fogging.

When Cleaning Is Possible vs. When Replacement Is Needed

| Condition | Cleanable? | Recommended Action |

|---|---|---|

| Light fogging, no visible residue | Yes | Venting with moisture absorption |

| Visible dust, debris, or streaks between panes | Yes | Micro-drilling and flushing |

| Cracked or broken glass | No | Full unit replacement |

| Severe mold or black residue | Possibly | Professional assessment required |

| Recent fogging after weather changes | Yes | Monitor; may resolve naturally |

Step-by-Step Guide to Cleaning Between Double Pane Windows

Cleaning the space between panes involves controlled access, contaminant removal, and moisture management. Follow this professional-grade process to achieve optimal results without damaging the window.

- Evaluate the Window Condition

Inspect both interior and exterior surfaces to confirm that the haze is inside the unit. Wipe down all accessible areas—if the fog remains, it's trapped internally. - Gather Tools and Materials

You’ll need:- Small drill with 1/8-inch carbide bit

- Compressed air can or small air pump

- Flexible plastic tubing (2–3 mm diameter)

- Isopropyl alcohol (90% or higher)

- Desiccant packets or silica gel

- Clear epoxy or sealant

- Rubber stopper or plug (optional)

- Select Drilling Points

Choose two locations on the outer edge of the outer pane—typically the top and bottom corners. Mark them lightly with a grease pencil. These will serve as entry and exit vents. - Drill Entry and Exit Holes

Using light pressure, drill through the outer pane at the marked points. Avoid cracking the glass by applying water as a coolant during drilling. Keep holes as small as possible—just large enough for the tubing. - Flush Out Debris and Moisture

Insert the tubing into the lower hole. Connect the other end to a compressed air source. Gently blow air into the cavity while tilting the window slightly downward to allow moisture and particles to drain. For stubborn residue, inject a few drops of isopropyl alcohol via syringe, then flush with air. - Dry the Interior Thoroughly

After flushing, leave the window open to airflow for 24–48 hours. Place desiccant packs near the holes to accelerate moisture absorption. Alternatively, use a hairdryer on cool setting held several inches away to encourage evaporation—never apply heat directly. - Seal the Holes

Once completely dry, seal the drilled holes with clear epoxy or UV-curing resin. Smooth the surface to match the glass contour. Some kits include rubber plugs for temporary sealing, but permanent closure ensures durability. - Monitor Results

Wait 3–5 days before assessing clarity. Condensation may reappear briefly due to residual humidity but should dissipate within a week under normal conditions.

Alternative: Professional Defogging Kits

For DIYers seeking a structured approach, commercial defogging kits like FogKlear or ClearView offer pre-packaged tools and instructions. These typically include micro-tubing, suction devices, drying agents, and sealants. While more expensive than raw materials, they reduce trial-and-error and improve success rates.

Real Example: Restoring a 10-Year-Old Bay Window

In suburban Ohio, homeowner Maria Thompson noticed persistent fogging in her living room bay window after a harsh winter. Believing replacement was inevitable, she received a $1,200 quote from a local contractor. Skeptical, she researched alternatives and attempted the micro-venting method described above.

Using a $35 drill bit and $10 in supplies, she carefully drilled two holes in the outer pane of each affected section. After flushing with compressed air and allowing three days of natural drying, the fog cleared significantly. She sealed the holes with marine-grade epoxy and reported 90% visibility restored. Over two years later, the windows remain clear, saving her over $1,000.

Maria’s experience reflects a growing trend: informed homeowners leveraging accessible techniques to extend window life. Her advice? “Don’t panic at the first sign of fog. Try a low-cost fix before writing off the whole unit.”

Common Mistakes to Avoid

- Using excessive force when drilling: This can crack the glass or damage the seal further.

- Skipping the drying phase: Sealing too soon traps moisture, causing fog to return quickly.

- Applying heat directly: Thermal shock can shatter tempered glass.

- Ignoring safety precautions: Wear goggles and gloves when drilling glass.

- Assuming all fog is permanent: Temporary condensation due to seasonal shifts often resolves on its own.

Do’s and Don’ts Summary

| Action | Do | Don't |

|---|---|---|

| Drilling | Use a diamond-coated bit with water cooling | Apply heavy pressure or use standard metal bits |

| Drying | Allow 24–72 hours with airflow and desiccants | Seal immediately after flushing |

| Cleaning Solution | Use isopropyl alcohol sparingly | Pour water or household cleaners into the gap |

| Sealing | Use optically clear epoxy rated for glass | Leave holes unsealed or use opaque caulk |

Frequently Asked Questions

Will drilling holes ruin the appearance of my window?

When done correctly, the holes are nearly invisible—about the size of a pinprick. Once sealed with clear epoxy, they blend into the glass surface. Most observers won’t notice them unless pointed out.

How long does a cleaned window stay clear?

If the original seal failure was minor and the drying process thorough, results can last 3–7 years. In some cases, especially with proper climate control indoors, clarity persists indefinitely. However, if the spacer or frame continues to degrade, re-fogging may occur.

Can I clean energy-efficient windows with gas fill the same way?

Yes, but with caveats. Argon or krypton-filled units lose their insulating gas when vented. While this reduces efficiency slightly (by about 10–15%), the improvement in visibility and elimination of moisture damage often outweighs the loss. The remaining air layer still provides better insulation than single-pane glass.

Final Checklist Before You Begin

- Confirm fog is between panes, not on surfaces.

- Check for cracks or physical damage—replace if present.

- Gather all tools: drill, tubing, air source, sealant, safety gear.

- Choose a dry, warm day with low humidity.

- Mark drilling points on the outer pane edge.

- Drill slowly with water cooling to prevent cracks.

- Flush cavity with air (and optional alcohol).

- Dry thoroughly for at least 24 hours.

- Seal holes with clear, durable epoxy.

- Monitor for 3–5 days for final results.

Conclusion: Clarity Without Costly Replacement

Cleaning between double pane windows without removing the glass is not only possible—it’s a smart, sustainable alternative to full replacement. By understanding the causes of internal fogging and applying precise, minimally invasive techniques, homeowners can restore window clarity, maintain energy efficiency, and avoid thousands in unnecessary renovation costs.

The key lies in early detection, careful execution, and realistic expectations. Not every fogged window can be saved, but many can. With the right knowledge and tools, you’re equipped to make that determination yourself.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?