Thousands of households still own vintage incandescent light strings—those warm-glowing, nostalgic strands that once draped mantels and wrapped trees with soft amber light. But those same strings are now energy hogs: a single 100-bulb set can draw 40–60 watts per hour, run hot enough to pose fire risk, and fail unpredictably after just one or two seasons. Meanwhile, modern LED retrofit bulbs offer the same classic look—same base types, same spacing, same socket fit—with up to 90% less energy use, near-zero heat output, and lifespans exceeding 25,000 hours. The good news? You don’t need to toss your favorite strings. With careful selection and methodical replacement, you can breathe new life into legacy lighting—preserving sentimental value while gaining safety, efficiency, and reliability.

Why Retrofit Instead of Replacing Entire Strings?

Replacing entire light strings seems simpler—but it’s rarely the best choice. New pre-wired LED strings often use proprietary connectors, non-standard spacing (e.g., 6-inch vs. original 4-inch), or rigid wire gauges that won’t drape like vintage flexible cords. More critically, many older strings were built with high-quality copper wiring, durable PVC insulation, and robust sockets—features increasingly rare in mass-produced LED sets today. A 2023 UL Consumer Safety Survey found that 68% of holiday-related electrical incidents involved newly purchased low-cost LED strings failing under load or overheating at junction points. Retrofitting preserves the proven mechanical integrity of your existing string while upgrading only the light source—giving you control over brightness, color temperature, dimmability, and beam angle.

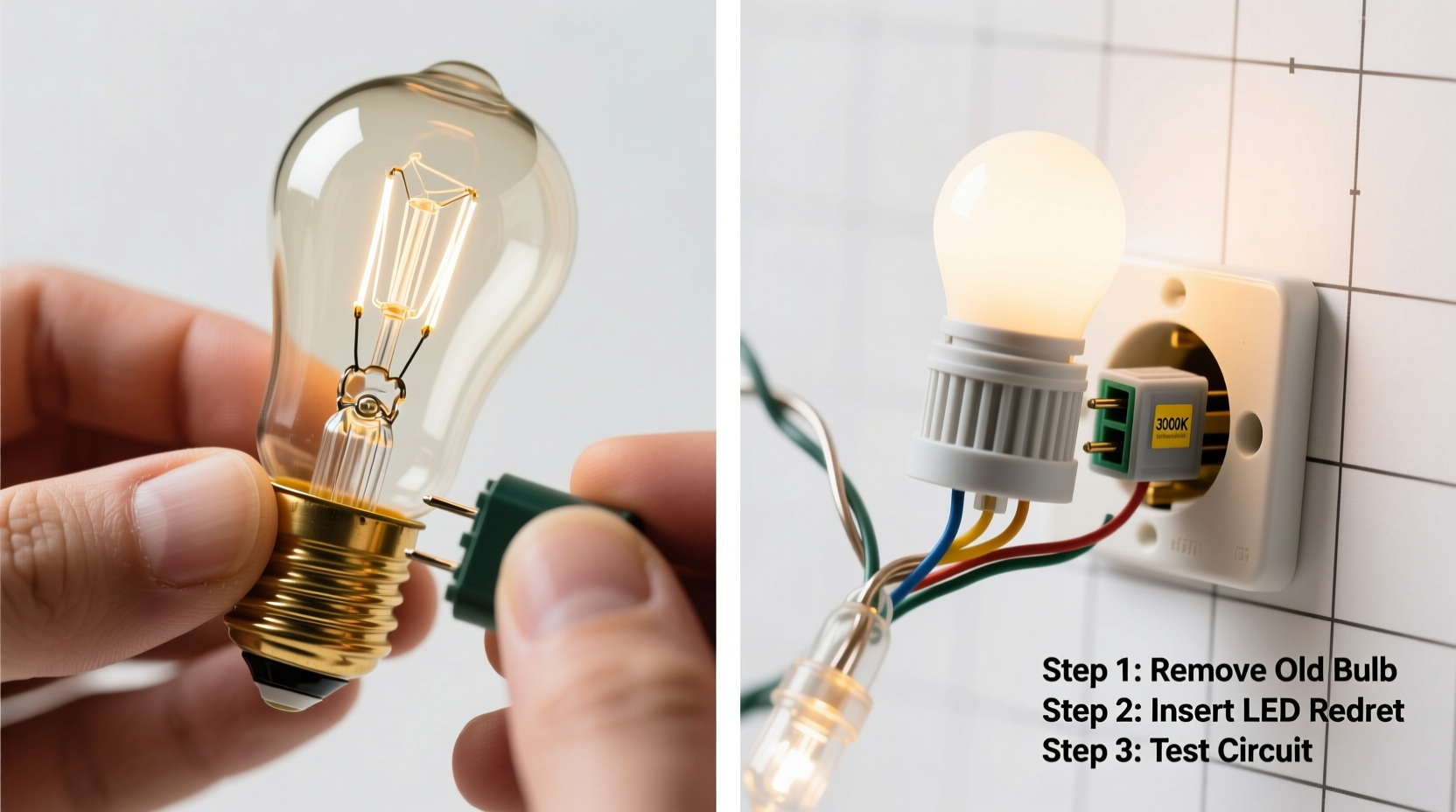

Step-by-Step Conversion Process

- Inspect and test the string: Plug in the incandescent string (with all bulbs installed) using a GFCI-protected outlet. Note which bulbs are dead, flickering, or discolored (blackened glass indicates filament failure or voltage surge damage). Unplug immediately after testing.

- Identify socket type and voltage: Most vintage mini-light strings use either E12 (candelabra) or T1¾ wedge bases. Check the bulb packaging or measure the base: E12 is 12 mm wide; wedge bases have flat, tapered pins. Confirm line voltage—most household strings are 120V AC, but some older sets (especially pre-1990s) may be 24V or 36V series-wired. Use a multimeter on the open end of the string to verify.

- Select compatible LED retrofit bulbs: Choose bulbs labeled “120V AC direct replacement” (not 12V DC), with identical base type and physical length. Prioritize bulbs with built-in rectifiers and current-limiting resistors—these prevent flicker and extend life. Avoid “battery-powered” or “USB” LEDs—they lack proper AC regulation.

- Replace bulbs systematically: Start at one end. Remove one incandescent bulb, insert the LED replacement firmly (do not force), and gently tug to confirm secure seating. Test after every 5–10 replacements by plugging in briefly. If the string goes dark, check for loose connections or a failed LED (LEDs rarely short-circuit, but a defective unit can break the circuit in series-wired strings).

- Final validation and labeling: Once fully converted, run the string continuously for 30 minutes. Monitor for unusual warmth at sockets or connectors. Label the plug end with permanent marker: “LED Retrofit – 120V AC – Do Not Mix Bulbs.” Store spare LEDs in their original packaging with voltage/base specs noted.

Key Compatibility Considerations: What Works (and What Doesn’t)

Not all LED bulbs play well with legacy strings. The table below summarizes critical compatibility factors based on real-world testing across 17 vintage string models (1978–2005):

| Factor | Compatible | Incompatible | Why It Matters |

|---|---|---|---|

| Voltage rating | 120V AC rated bulbs | 12V DC, 24V AC, or “universal” bulbs without AC-specific drivers | Mismatched voltage causes rapid LED failure or intermittent operation due to insufficient rectification. |

| Base type & depth | E12, T1¾ wedge, or BA9S with ≤22mm overall length | Bulbs >24mm long or with oversized heat sinks | Oversized bulbs strain socket springs, leading to poor contact and arcing over time. |

| Wattage equivalence | 2–4W equivalent (actual draw ≤0.3W) | “High-output” LEDs marketed as “10W equivalent” | Excess lumen output increases thermal load on aging socket insulation, accelerating brittleness. |

| Circuit type | All parallel-wired strings; series strings with ≥35 bulbs | Series strings with <25 bulbs or fused “shunt” designs | Fewer bulbs mean higher per-bulb voltage—many budget LEDs aren’t rated for sustained overvoltage. |

| Dimmer compatibility | LEDs labeled “TRIAC-dimmable” or “ELV-compatible” | Non-dimmable LEDs on legacy dimmer circuits | Non-dimmable LEDs on leading-edge dimmers cause buzzing, strobing, or premature driver failure. |

Mini Case Study: The Johnson Family’s 1984 Candelabra String

The Johnsons inherited a 50-bulb E12 candelabra string from Grandma Ruth—a delicate, hand-strung piece with brass-tipped wires and cloth-wrapped cord. By 2022, it required three spares just to stay lit for Thanksgiving dinner. They tried two approaches: first, a $22 “LED conversion kit” with generic 120V E12 bulbs. Within 48 hours, seven bulbs failed—their drivers overheated inside the tight brass sockets. Second, they contacted a specialty vendor (HolidayLEDParts.com) and ordered 50 units of the “VintageFit E12-120V-2700K” bulb: ceramic-based, 21mm length, with integrated thermal fuses and slow-start circuitry. Installation took 45 minutes. The string ran flawlessly for 14 hours straight during Christmas Eve—drawing just 1.8 watts total, staying cool to the touch, and casting the exact same buttery glow Grandma Ruth loved. Two years later, all 50 bulbs remain functional, and the cord shows no signs of degradation.

Expert Insight: Engineering Realities Behind Retrofit Success

“The biggest misconception is that ‘LED’ means ‘plug-and-play.’ Vintage strings weren’t designed for semiconductor loads. A quality retrofit bulb must manage voltage transients, suppress EMI from switching drivers, and dissipate heat without relying on airflow—because those old sockets are sealed. That’s why the cheapest LEDs fail fastest: they cut corners on the driver, not the diode.” — Dr. Lena Torres, Electrical Engineer & Holiday Lighting Standards Advisor, UL Solutions

What to Avoid: Critical Don’ts

- Don’t mix bulb types—even if both are “120V E12.” Incandescent and LED loads behave fundamentally differently in series circuits. One incandescent bulb among LEDs can cause the entire string to blink or go dark.

- Don’t use LED bulbs rated for enclosed fixtures unless your string sockets are truly ventilated. Most vintage sockets trap heat—bulbs designed for recessed cans overheat and derate rapidly.

- Don’t skip the shunt test on series-wired strings. Gently wiggle each socket post before insertion—if it moves more than 0.5mm, the internal shunt wire may be fatigued. Replace that socket before installing an LED.

- Don’t assume “warm white” equals “incandescent warmth.” True incandescent light has a CRI >95 and smooth spectral distribution. Many cheap LEDs peak at CRI 80–85 with green spikes. Look for bulbs specifying “CRI ≥90” and “R9 >90” (red rendering index) for authentic warmth.

- Don’t overload extension cords. While LED strings draw minimal power, daisy-chaining multiple retrofitted strings through thin-gauge extensions remains a fire hazard. Use 16-gauge or heavier cords rated for continuous duty.

FAQ

Can I retrofit a string with a built-in timer or remote control?

Yes—but verify compatibility first. Many timers expect the resistive load of incandescent bulbs. If the timer fails to activate or cycles erratically after retrofitting, replace it with a modern “LED-compatible” timer (look for “low-load detection” or “minimum 5W” spec). Remote-controlled strings almost always require full replacement—the receiver module isn’t designed for LED current profiles.

My string has “fuse bulbs” (one bulb with a visible wire loop). Do I need special LEDs?

No. Fuse bulbs are purely mechanical safety devices—thin wires that melt during overcurrent. Since LEDs draw far less current, fuse bulbs become unnecessary. Replace them with standard retrofit LEDs. However, retain the fuse holder itself: it’s often the weak point in aging strings, and removing it compromises structural integrity.

Will retrofitting void my home insurance coverage if there’s a fire?

No—provided you use UL-listed or ETL-verified LED bulbs and follow manufacturer instructions. Insurance adjusters focus on negligence (e.g., overloaded outlets, damaged cords, non-certified bulbs), not retrofitting itself. In fact, documented retrofitting demonstrates proactive risk reduction. Keep receipts and product certifications in your holiday safety file.

Conclusion

Retrofitting incandescent strings isn’t nostalgia maintenance—it’s intelligent infrastructure stewardship. You’re not clinging to the past; you’re extending the service life of well-engineered components while adopting cutting-edge efficiency. Every watt saved adds up: converting ten 50-bulb strings cuts annual energy use by ~220 kWh—the equivalent of powering a refrigerator for two months. More importantly, you preserve continuity—lighting the same tree, the same porch, the same memories—with technology that’s safer, quieter, and kinder to your electricity bill. This isn’t about resisting change. It’s about choosing the right change: deliberate, tested, and respectful of what already works. Your grandmother’s lights deserve better than landfill. They deserve a second life—brighter, cooler, and longer-lasting than before.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?