Understanding the true power output of an engine is essential for performance tuning, vehicle comparison, and mechanical diagnostics. Horsepower—the unit that measures an engine’s ability to perform work over time—is more than just a number on a spec sheet. Accurately measuring it requires the right tools, techniques, and awareness of influencing factors. Whether you're a car enthusiast, mechanic, or DIY builder, knowing how to find horsepower reliably can transform your approach to vehicle performance.

This guide walks through proven methods to measure horsepower with precision, from professional dynamometer testing to accessible estimation techniques. You’ll learn what affects accuracy, how to interpret results, and how to apply this knowledge in real-world scenarios.

Understanding Horsepower: The Basics

Horsepower (hp) was originally coined by James Watt to compare steam engines to draft horses. Today, it quantifies how much work an engine can do per minute. One mechanical horsepower equals 550 foot-pounds per second, or about 745.7 watts. In automotive terms, horsepower reflects how quickly a vehicle can accelerate, climb hills, or maintain speed under load.

There are two primary types of horsepower measurements:

- Brake Horsepower (bhp): Measured at the engine’s crankshaft, without accounting for drivetrain losses.

- Wheel Horsepower (whp): Measured at the drive wheels, reflecting real-world usable power after transmission, differential, and friction losses.

The difference between bhp and whp typically ranges from 15% to 20%, depending on the drivetrain configuration (FWD, RWD, AWD) and efficiency.

“Many people quote engine specs, but wheel horsepower tells the real story of performance.” — Carlos Mendez, Automotive Dyno Specialist

Methods to Measure Horsepower Accurately

Several methods exist to determine horsepower, each with varying degrees of precision, cost, and accessibility. Choosing the right one depends on your goals, budget, and technical comfort level.

1. Using a Dynamometer (Dyno)

A dynamometer is the gold standard for measuring horsepower. It applies controlled resistance to the engine or wheels and calculates power based on torque and rotational speed.

Two main types are used in practice:

| Type | Measurement Point | Accuracy | Best For |

|---|---|---|---|

| Engine Dyno | Crankshaft (bhp) | Very High | Race shops, engine builders |

| Chassis Dyno | Drive wheels (whp) | High | Tuners, performance garages |

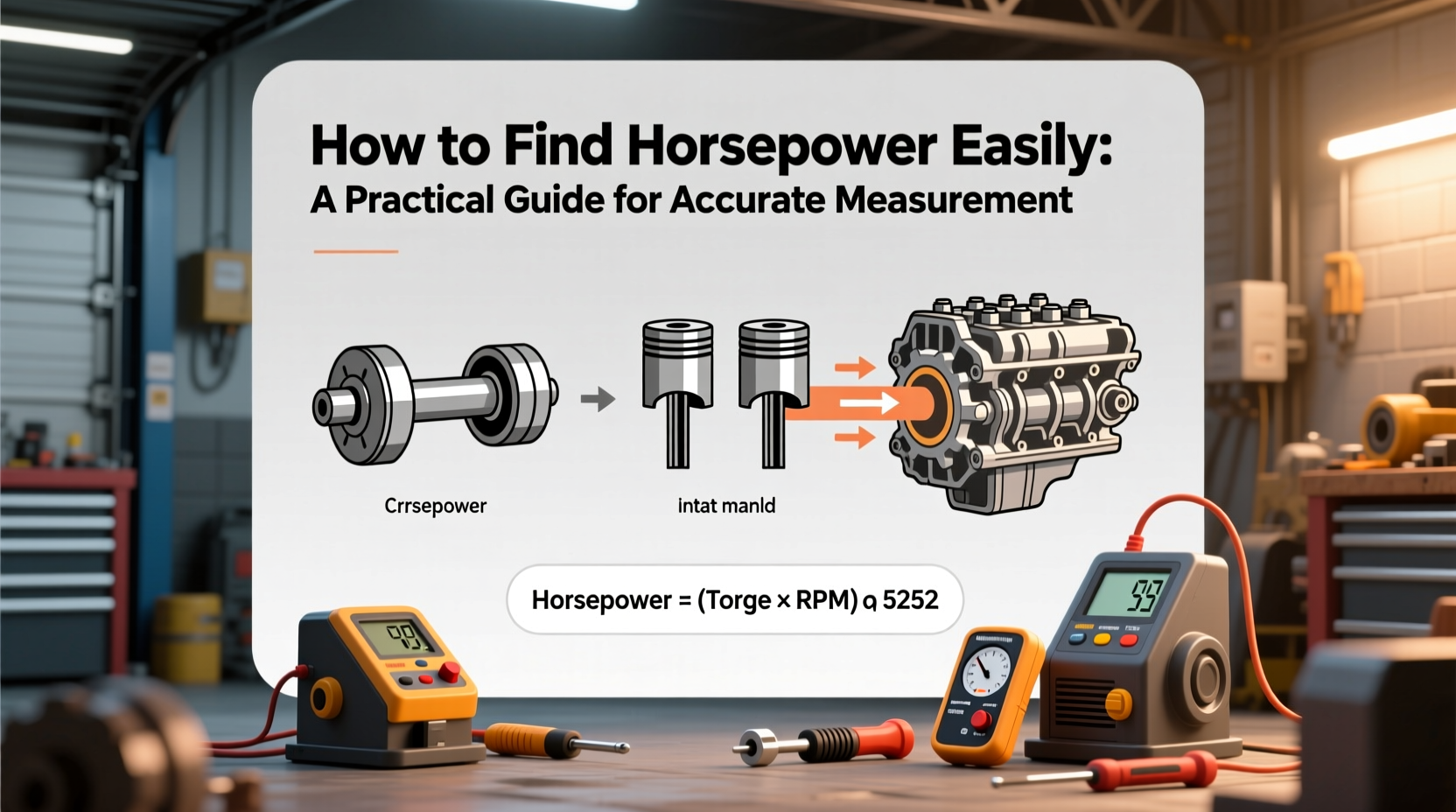

During a dyno test, the vehicle is secured, and the driver performs a full-throttle run in a single gear. Software records torque and RPM, then calculates horsepower using the formula:

Horsepower = (Torque × RPM) / 5252

Professional dynos also account for atmospheric conditions (temperature, humidity, pressure), applying correction factors (like SAE or STP) to ensure consistent readings across different environments.

2. Onboard OBD2 Devices and Apps

Modern vehicles equipped with OBD2 ports allow access to real-time engine data, including RPM and torque. Some advanced scan tools and smartphone apps estimate horsepower using factory sensor inputs.

While not as precise as a dyno, these tools offer a convenient way to track relative changes—such as before and after installing a cold air intake or performance chip.

Popular devices like the OBDeleven, Torque Pro, or HP Tuners can log data and calculate estimated wheel horsepower when paired with GPS-based acceleration tracking.

3. GPS-Based Acceleration Calculators

This method uses the physics of motion to estimate power. By measuring how fast a vehicle accelerates over a set distance (e.g., 0–60 mph or 1/4 mile), and knowing its weight, you can derive approximate horsepower.

The basic formula involves:

- Measuring elapsed time (ET) over a known distance (e.g., 1/4 mile).

- Determining total vehicle weight (including driver and fuel).

- Using empirical formulas like the Huntington Formula:

hp ≈ (Weight^(2/3)) × (Speed / 225.06)

Or simpler online calculators that take ET and weight to return estimated horsepower.

While less accurate than a dyno, this method is free, repeatable, and useful for spotting performance trends.

Step-by-Step Guide to Measuring Horsepower at a Dyno Shop

If you’re planning a professional dyno session, follow this sequence to ensure reliable results:

- Schedule with a reputable shop – Choose one with updated equipment and experience in your vehicle type.

- Prepare your vehicle – Ensure proper fluid levels, tire pressure, and no check-engine lights.

- Warm up thoroughly – Run the engine until operating temperature stabilizes.

- Secure the vehicle – Technicians will strap it down and connect cooling fans to prevent overheating.

- Perform baseline runs – Usually 2–3 pulls to establish consistency.

- Analyze the data – Review the hp and torque curves, noting peak values and shape.

- Compare corrected vs. uncorrected numbers – Ask for both; corrected figures normalize environmental variables.

After the test, you’ll receive a printout showing horsepower and torque across the RPM range—a valuable tool for tuning decisions.

Common Mistakes That Skew Horsepower Readings

Even with the right tools, inaccurate measurements happen due to avoidable errors. Be aware of these pitfalls:

- Inconsistent testing conditions: Temperature swings affect air density and engine output.

- Short warm-up periods: Cold oil and coolant reduce efficiency and power delivery.

- Incorrect tire pressure or traction: Wheel slip during a dyno run inflates RPM without real power gain.

- Ignoring altitude: Higher elevations reduce oxygen, lowering horsepower unless corrected.

- Using uncalibrated equipment: Consumer-grade sensors may drift over time.

Mini Case Study: Tuning a Modified Civic

Jamal, a Honda enthusiast, installed a performance exhaust, cold air intake, and ECU tune on his 2018 Civic Si. Before and after modifications, he visited a local dyno shop.

The first run showed 185 wheel horsepower—slightly below stock expectations due to high ambient temperature. After correcting for conditions, the technician reported 192 hp, close to factory claims.

Post-modification, Jamal returned under similar conditions. The new runs averaged 218 wheel horsepower, confirming a real 26 hp gain. Without the baseline comparison and environmental correction, he might have misjudged the upgrade’s impact.

This example highlights why controlled, repeatable testing matters—especially when investing in performance parts.

Checklist: How to Get Reliable Horsepower Measurements

Use this checklist before any measurement session:

- ✅ Verify all vehicle systems are functioning (no error codes)

- ✅ Check tire pressure and condition

- ✅ Use a full tank of the same fuel grade for consistency

- ✅ Warm up engine and drivetrain to normal operating temperature

- ✅ Record ambient temperature, humidity, and barometric pressure

- ✅ Perform multiple runs to ensure repeatability

- ✅ Request corrected horsepower data (SAE or STP standard)

Frequently Asked Questions

Can I measure horsepower at home without a dyno?

Yes, using GPS-based timing apps like Dragy or RaceRender combined with your vehicle’s weight can give a reasonable estimate. While not lab-grade accurate, it’s effective for tracking changes over time.

Why is my wheel horsepower lower than the manufacturer's claimed horsepower?

Manufacturers usually report engine horsepower (bhp), measured at the crankshaft. Wheel horsepower accounts for drivetrain losses—typically 15–20% in automatics and 12–15% in manuals—so a lower number is normal and expected.

How often should I test my vehicle’s horsepower?

Test whenever you make a significant modification, notice performance drops, or as part of annual maintenance for tuned or high-performance vehicles. Regular testing helps catch issues like clogged intakes or failing turbos early.

Conclusion: Take Control of Your Vehicle’s Performance

Knowing how to find horsepower easily and accurately empowers you to make informed decisions about upgrades, maintenance, and tuning. Whether you use a professional dyno, onboard diagnostics, or physics-based calculations, consistency and context are key. Focus on repeatable methods, control external variables, and always interpret numbers relative to real-world conditions.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4

Comments

No comments yet. Why don't you start the discussion?